ECO-CCE - AstralPool

ECO-CCE - AstralPool

ECO-CCE - AstralPool

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ECO</strong> COUNTER-CURRENT EQUIPMENT<br />

king glands (37) in place gently pull the two<br />

conduits so that thay do not remain bent inside<br />

the case. Lead the control conduit (22) to the<br />

control cabinet and set it up inside the wall conduit.<br />

Put the air inlet valve (20) onto the end of<br />

the suction tube (14), its design allowing it to be<br />

fixed onto the wall above the water level.<br />

If you cannot get to the back end of the housing<br />

case then the suction and control conduits (14)<br />

and (22) must be sealed from inside the housing<br />

case. Put the two packing glands PG16<br />

(37) with the seals onto the conduits and pass<br />

them through the packing gland holes and protection<br />

tubes (assembled before-hand in the<br />

housing case. See (Fig. 3). Put the return inlet<br />

unit next to the return pipe (31) and before<br />

fixing the packing glands slide through the conduits,<br />

leaving the least possible length free to<br />

fix the packing glands, so that when you introduce<br />

the return inlet unit fully into the housing<br />

case the conduits (14) and (22) don't bend.<br />

Lead the control conduit (22) to the control<br />

cabinet and assemble it inside the wall conduit.<br />

Put the valve (20) onto the end of the suction<br />

tube (14).<br />

The propulsion outlet unit is situated right<br />

against the pool wall, fix it in place using 4<br />

screws depending on the thickness of the surface<br />

finish.The assembly allows a tolerance of<br />

0-70 mm.<br />

Glue the PVC piping from the flange connection<br />

to the siting of the pump, the installation of<br />

valves is recommended here for future maintainance<br />

operations.<br />

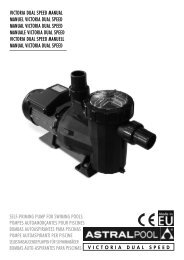

The pump is fixed onto the floor on cushions<br />

and in a horitzontal position. The 2 outlets of<br />

the pump will be connected to the tubes<br />

coming from the housing case.<br />

2c. Assembly of the unit in liner pools<br />

For this installation, a set of fittings composed<br />

(48), of the flange and sealing gaskets is required.<br />

Installation of the unit is the same as described<br />

beforehand.<br />

2d. Installation of the unit in pre-fabricated<br />

pools<br />

For installation of the unit in pre-fab. pools,<br />

a set of fittings (48), composed of a flange<br />

and sealing gaskets is required. For<br />

assembly instructions procede as described<br />

beforehand.<br />

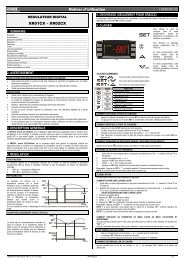

3. ELECTRICAL INSTALLATION<br />

The electrical installation must be made in<br />

accordance with the regulations concerning<br />

electrical protection in force in each country.<br />

The installation should be made by an<br />

authorised installer. Check that the voltage<br />

coincides with the specifications plaque of the<br />

pump. Use a power cable of 5x4 mm². for the<br />

pump 3,3 kW., of 5x2,5 mm². for the pump 2,6<br />

kW. and 3x2,5 mm². for the 1,5 kW. pump. For<br />

protection, install 16 amp. fuses, and without<br />

fail a circuit breaker of 25/0.03 A. (30 mA).<br />

The control cabinet comes with the following<br />

components: A thermal relay to ensure the protection<br />

of the motor, which must be correctly<br />

regulated, according to the current consump-<br />

5<br />

ENGLISH<br />

<strong>ECO</strong> <strong>CCE</strong>