SINGLE-LAYER ROLLER KILN HORNO DE ... - Sacmi Forni

SINGLE-LAYER ROLLER KILN HORNO DE ... - Sacmi Forni

SINGLE-LAYER ROLLER KILN HORNO DE ... - Sacmi Forni

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

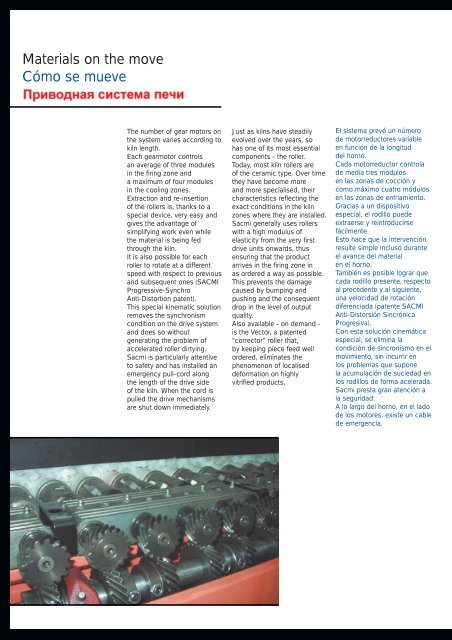

Materials on the moveCómo se mueveThe number of gear motors onthe system varies according tokiln length.Each gearmotor controlsan average of three modulesin the firing zone anda maximum of four modulesin the cooling zones.Extraction and re-insertionof the rollers is, thanks to aspecial device, very easy andgives the advantage ofsimplifying work even whilethe material is being fedthrough the kiln.It is also possible for eachroller to rotate at a differentspeed with respect to previousand subsequent ones (SACMIProgressive-SynchroAnti-Distortion patent).This special kinematic solutionremoves the synchronismcondition on the drive systemand does so withoutgenerating the problem ofaccelerated roller dirtying.<strong>Sacmi</strong> is particularly attentiveto safety and has installed anemergency pull-cord alongthe length of the drive sideof the kiln. When the cord ispulled the drive mechanismsare shut down immediately.Just as kilns have steadilyevolved over the years, sohas one of its most essentialcomponents - the roller.Today, most kiln rollers areof the ceramic type. Over timethey have become moreand more specialised, theircharacteristics reflecting theexact conditions in the kilnzones where they are installed.<strong>Sacmi</strong> generally uses rollerswith a high modulus ofelasticity from the very firstdrive units onwards, thusensuring that the productarrives in the firing zone inas ordered a way as possible.This prevents the damagecaused by bumping andpushing and the consequentdrop in the level of outputquality.Also available - on demand -is the Vector, a patented“corrector” roller that,by keeping piece feed wellordered, eliminates thephenomenon of localiseddeformation on highlyvitrified products.El sistema prevé un númerode motorreductores variableen función de la longituddel horno.Cada motorreductor controlade media tres módulosen las zonas de cocción ycomo máximo cuatro módulosen las zonas de enfriamiento.Gracias a un dispositivoespecial, el rodillo puedeextraerse y reintroducirsefácilmente.Esto hace que la intervenciónresulte simple incluso duranteel avance del materialen el horno.También es posible lograr quecada rodillo presente, respectoal precedente y al siguiente,una velocidad de rotacióndiferenciada (patente SACMIAnti-Distorsión SincrónicaProgresiva).Con esta solución cinemáticaespecial, se elimina lacondición de sincronismo en elmovimiento, sin incurrir enlos problemas que suponela acumulación de suciedad enlos rodillos de forma acelerada.<strong>Sacmi</strong> presta gran atención ala seguridad:A lo largo del horno, en el ladode los motores, existe un cablede emergencia.