CURVAMATIC-2 - Ega Master

CURVAMATIC-2 - Ega Master

CURVAMATIC-2 - Ega Master

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

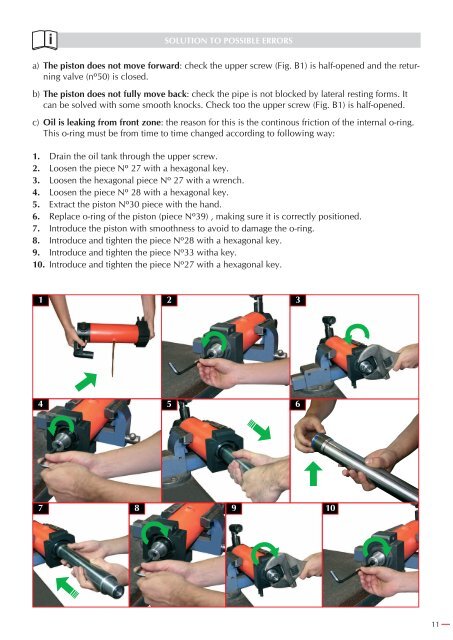

SOLUTION TO POSSIBLE ERRORSa) The piston does not move forward: check the upper screw (Fig. B1) is half-opened and the returningvalve (nº50) is closed.b) The piston does not fully move back: check the pipe is not blocked by lateral resting forms. Itcan be solved with some smooth knocks. Check too the upper screw (Fig. B1) is half-opened.c) Oil is leaking from front zone: the reason for this is the continous friction of the internal o-ring.This o-ring must be from time to time changed according to following way:1. Drain the oil tank through the upper screw.2. Loosen the piece Nº 27 with a hexagonal key.3. Loosen the hexagonal piece Nº 27 with a wrench.4. Loosen the piece Nº 28 with a hexagonal key.5. Extract the piston Nº30 piece with the hand.6. Replace o-ring of the piston (piece Nº39) , making sure it is correctly positioned.7. Introduce the piston with smoothness to avoid to damage the o-ring.8. Introduce and tighten the piece Nº28 with a hexagonal key.9. Introduce and tighten the piece Nº33 witha key.10. Introduce and tighten the piece Nº27 with a hexagonal key.1 2 34 5 67 8 9 1011