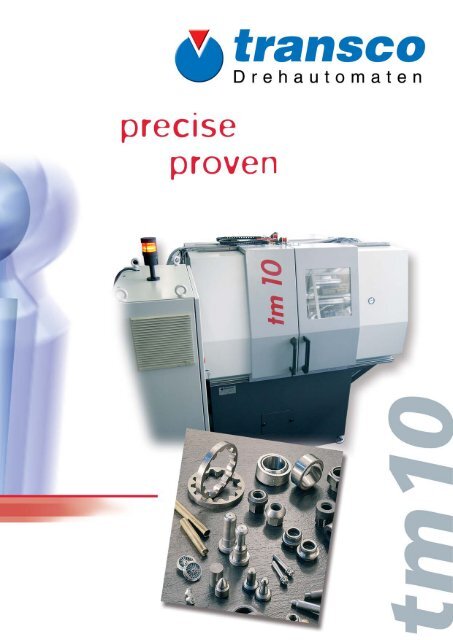

tm 10 single spindle automatic lathe - Transco Drehautomaten

tm 10 single spindle automatic lathe - Transco Drehautomaten

tm 10 single spindle automatic lathe - Transco Drehautomaten

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

technology performance<br />

The machine series AUDREMA® <strong>tm</strong><strong>10</strong><br />

is based on the successes of the proved<br />

AUDREMA 8032. With this development<br />

the requirements of second operation<br />

machining standards in repetitive<br />

production were particularly taken into<br />

consideration. Most remarkable detail of<br />

the new machine series <strong>tm</strong><strong>10</strong> is the new<br />

designed protective hood.<br />

Combined with this new development<br />

extensive modifications were carried out<br />

on the machine bed, the handling of<br />

work pieces as well as chips separation,<br />

which finally also leads to an extension<br />

of the manufacturing spectrum.<br />

Beyond that ergonomic improvements<br />

result for the operation of the machine.<br />

The combination of high performance<br />

and precise repeatability correspond to<br />

the requirements of second operation<br />

machining in the medium and large<br />

batch production. It goes without saying<br />

that existing machinery equipment of<br />

the predecessor series 8032 can still be<br />

used with the new <strong>tm</strong><strong>10</strong>. The machinery<br />

variety of the new <strong>tm</strong><strong>10</strong> provides the<br />

customer with optimum machine layout<br />

for production.<br />

<strong>tm</strong><strong>10</strong><br />

transco <strong>Drehautomaten</strong> GmbH<br />

Kemptener Strasse 75<br />

D - 87629 Füssen<br />

Phone (++49) (+8362) 9186 - 0<br />

Fax (++49) (+8362) 9186 - 99<br />

info@transco-gmbh.de<br />

www.transco-gmbh.de<br />

� loading times with collet chucking<br />

free drop < 1,0 sec.<br />

guided drop < 1,5 sec<br />

� loading times with 3-jaw chucking<br />

guided drop < 2 sec.<br />

� capacity of up to 35 parts per minute<br />

� maintenance-free precision <strong>spindle</strong> bearings<br />

� PLC control for master functions<br />

� high performance drives of up to 9 kW<br />

� independent camshaft speed<br />

multiple variable during cycle<br />

� mechanical feed cams<br />

� interchangeable chucking devices<br />

pull collet / push collet<br />

overhead chuck<br />

power-operated <strong>lathe</strong> arbor<br />

special chucking devices<br />

on request<br />

� interchangeable tool carriers<br />

radial slides<br />

cross-slide radial-axial<br />

multiple cross-slide with guide ruler<br />

straight-turning slide<br />

<strong>spindle</strong> sleeve tools for<br />

drilling operations<br />

hydraulic ball turning unit<br />

� extensive program of feeding systems for:<br />

parts with head, discs, rollers, pins,<br />

headless parts etc.<br />

position identification and position<br />

change in the intake possible<br />

multiple chucking possible<br />

� Spindle sleeve tool for drilling- and<br />

tapping operations<br />

� Standard size range: Length up to 140 mm (120<br />

mm shank + 20 mm head) diameter up to 30 mm<br />

� Optional clamping tools on request