WiN woodworking INTERNATIONAL 2020/3

- Text

- Woodworking magazine

- Woodworking

- August

- Products

- Materials

- Circular

- Robot

- Blades

- Profiles

- Briquetting

- Extraction

- Harnischcom

SAFETY Höcker

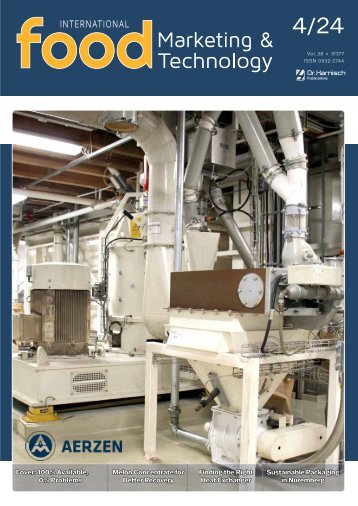

SAFETY Höcker Polytechnik now utilises the highest efficiency category IE5 permanent magnet motor 25 % improved chip particle extraction The cost of energy production is growing from year to year - reduced energy costs thus become a decisive competitive advantage. When the processing machine is started in production, the dust collector also operates in parallel. A reduction in power consumption for dust and chip extraction can therefore quickly pay for itself. Dedusting at the highest energy efficiency level Vacumobil JP350 with IE5 efficiency power pack with jet/compressed air pulse cleaning and integrated briquetting press. Höcker Polytechnik, one of the leading companies for extraction and filter technology, has been able to reduce the power consumption of its Vacumobil dust extractors considerably by using the modern IE5 permanent magnet motor technology. Motor of the highest efficiency class IE5 The newly developed IE5 Efficiency Powerpack offers an efficiency advantage through reduced power costs with increased extraction capacity of up to 25 percent. This leap in performance is made possible by using permanent magnet motors of the highest IE5 efficiency class in conjunction with specially parameterised frequency inverters. Energy efficiency class 5, or Ultra Premium Efficiency, is currently the highest efficiency class for electric motors. In the Vacumobil dust collectors, this ultra-modern motor type, which is also often used in electric cars, ensures a considerable increase in efficiency. Höcker Polytechnik has coupled the permanent magnet motor with a frequency converter and adapted the control electronics especially for this motor type. These three ultra-modern components make the 1000 times proven Vacumobiles to the probably most economical dust collectors on the market. Successfully tested in practice A Vacumobil 350 dust collector with such an IE5 power pack was tested in a six-month stress test at a furniture manufacturer in real working conditions. The result was convincing: the Vacumobil with the 11 kW permanent magnet motor (IE5) reliably took over the job for which a Vacumobil with a frequency-controlled 15 kW asynchronous motor (IE3) was previously required. However, it effectively consumes 2.5 kW less power. In annual terms, the additional cost of using a Vacumobil with IE5 Efficiency Powerpack can therefore already be recouped. The increased suction capacity offers additional added value. Energy efficiency is not only rewarded by a lower electricity bill, the purchase of this IE5 Vacumobil dust collector is supported by the Bafa subsidy program. The new IE5 Efficiency Powerpack is available in combination with the Vacumobil models 350 (11 kW/IE5), 300 (7.5 kW/ IE5) or 250 (5.5 kW/IE5). www.hoecker-polytechnik.de Red Dot Design Award Explosion safety systems win for the first time When it comes to the winners of design awards, most people think of futuristic automobiles, furnishings or everyday objects. However, for the first time, protection systems have now also received an award. Two in-house developments from the German safety manufacturer REMBE, known as the world market leader on the explosion safety scene, have received the Red Dot Design Award: the Q-Bic extinguishing barrier and the design study for a new generation of the EXKOP quench valve, both products for explosion isolation. The REMBE engineers have thus demonstrated that, besides the highest standards of safety and reliability, they also have an eye for the visual. However, not only does the new Q-Bic isolation system look good but the design has been developed with functional and hygienic aspects in mind. The Q-Bic extinguishing barrier offers a variety of visible and invisible highlights: the firmly attached transport handles, which allow safe installation and transport of the extinguishing barriers, are obvious. They are very helpful, especially when the Q-Bic is installed in hard-to-reach places or at high altitudes. Thanks to the convex dirt protection cap, neither water nor dust deposits can accumulate on the Q-Bic. The “inner values” of the Q-Bic are also remarkable: the blue-green extinguishing powder QXP prevents cross-contamination and the patented SJX nozzle ensures an optimum application of the extinguishing powder. Thanks to the specially developed release mechanism without explosives, the Q-Bic can be easily imported worldwide. The Q-Bic is particularly suitable for large pipes attached to dryers and filters or complex shaft geometries such as conveyors and elevators. www.rembe.de Winner of the Red Dot Design Award: REMBE Q-Bic. 18 No. 3 • August 2020

ARCHITECTURE Reduce the climate impact of Sweden’s largest wood housing development The construction industry accounts for a quarter of Sweden’s climate footprint, with the majority of the impact occurring in the production and materials transport phases. The purpose of this collaboration is to identify where the carbon emissions occur and what choices can be made in terms of materials and methods to bring those emissions down. Within Folkhem’s Cederhusen project, Stockholm’s first inner city district to be built in wood, a collaborative group of experts in various fields has been put together, with members from the industry body Swedish Wood, Folkhem/ Veidekke Eiendom, Veidekke Entreprenad, Zynka BIM, Bjerking and Vertex Systems. The aim is to make serious advances in the development of quality assured and active climate work through every phase of a construction project by using a current, real-life project. “We have high ambitions for this project on every front; and in terms of the climate impact, we want to find out how choices made early on in the process can cut emissions,” says Anna Ervast Öberg, head of project development for wooden buildings at Folkhem/Veidekke Eiendom, who continues: “It’s also about finding systems and methods that prepare us for the imminent legal requirement that buildings must come with a climate declaration, but it’s at least as important to gather correct climate data as a support for decision-making in our processes.” “The wood industry has a huge role to play in the current green transition. Our job is to help our member companies develop their own knowledge and tools, and so help to educate the whole construction sector, and we want show what can be done in an actual project based on the tools and know-how we already have. Now the next stage of development is to focus on standardising data and systematising information,” comments Johan Fröbel, Head of Technology and Distribution at Swedish Wood. Project manager Christer Green, from Swedish Wood and Christer Green Affärsutveckling, confirms that the timing is good, and highlights commercial benefit as a prime driver: “The time is now right for developers to begin placing requirements on suppliers and manufacturers. It creates an incentive for these parties to develop the right processes and tools. It’s about raising standards along the whole construction chain, so that as well as benefiting the climate we can develop a considerably more resource-efficient building process.” www.swedishwood.com No. 3 • August 2020 19

- Seite 1 und 2: ISSN 1438-1672 · Vol. 38 · No. 3/

- Seite 3 und 4: EDITORIAL Eric Schäfer Editor It's

- Seite 5 und 6: Impressum ISSN 1438-1672 WiN - wood

- Seite 7 und 8: COMPANIES Dream Villa in German Tus

- Seite 9 und 10: COMPANIES Giardina Group takes over

- Seite 11 und 12: MACHINING TECHNOLOGY Pressing and s

- Seite 13 und 14: SCIENCE The use of adhesive bonding

- Seite 15 und 16: SCIENCE Fully carbide-tipped circul

- Seite 17: TOOLS The silent saw Silence, to ke

- Seite 21 und 22: ARCHITECTURE On trend - wood for in

- Seite 23 und 24: DECORS Fully automated flexographic

- Seite 25 und 26: SURFACES High-end designs made poss

- Seite 27 und 28: USER REPORT The EOAT with the six K

- Seite 29 und 30: USER REPORT Warehouse for wooden pl

- Seite 31 und 32: EVENTS First Rosenheim LIGNA.Confer

- Seite 33 und 34: FAIRS New dates and formats for Fer

- Seite 35 und 36: Guide to Products and Manufacturers

Unangemessen

Laden...

Magazin per E-Mail verschicken

Laden...

Einbetten

Laden...