D DK E F FIN GB I N NL S PL GR CZ - Rameder Attelage

D DK E F FIN GB I N NL S PL GR CZ - Rameder Attelage

D DK E F FIN GB I N NL S PL GR CZ - Rameder Attelage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

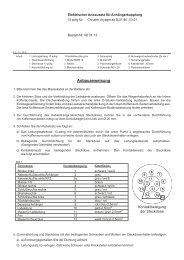

Type: 313 142 Version A<br />

Scope of delivery of trailer bracket:<br />

Item Designation Number<br />

1 Trailer bracket 1<br />

2 Support 2<br />

3 Counter-piece 2<br />

4 Fishplate 2<br />

5 Spacer pipe 4<br />

6 Hexagon bolt M12x1,5x100, strength class 10.9 8<br />

7 Hexagon bolt M10x90, strength class 10.9 4<br />

8 Hexagon bolt M10x110, strength class 10.9 4<br />

9 Hexagon bolt M10x30, strength class 10.9 4<br />

10 Collar nut M10, strength class 10 4<br />

11 Hexagon nut M10, strength class 10 8<br />

12 Hexagon nut M12x1,5, strength class 10 8<br />

13 Washer 13x24x2,5 16<br />

14 Installation instructions 1<br />

Available spare parts for trailer bracket<br />

Spare part no. Designation<br />

913 153 650 001 Pack of mounting parts (items 3-14)<br />

Installation Instructions:<br />

1.) Remove spare wheel from holder. Detach/remove exhaust system as necessary.<br />

2.) Hold trailer bracket 1 under vehicle and align at ”a” with bores on vehicle. Insert hexagon bolts M12 with washers<br />

13 at ”a”, fit counter-pieces 3 and loosely secure with washers 13 and hexagon nuts M12.<br />

3.) Position supports 2 (ensure correct positions on left and right) at ”b” on trailer bracket 1, insert hexagon bolts<br />

M10x30 and loosely secure with securing nuts M10.<br />

4.) Align supports 2 and position on vehicle frame side member (inner). Ensure dimension 25 mm (see<br />

section A-A). Mark vehicle frame side member (inner) at ”c”. Remove supports 2 at ”b”.<br />

5.) Mark centre of vehicle frame side member (inner) at ”c”. Drill holes (10,5 mm dia.) in vehicle frame side<br />

member inner and outer struts. (Ensure correct angle). Drill outer strut of vehicle frame side member to 18,5 mm.<br />

Deburr bores (see section A-A).<br />

6.) Mount supports 2 at ”b”. Insert hexagon bolts M10x90 at ”c”, fit spacers 5 at ”c” (from outside), fit fishplates 4<br />

at ”c” and secure with securing nuts M10.<br />

7.) Align trailer bracket and tighten hexagon bolts and nuts.<br />

8.) Bolt the ball plate onto the towing bracket 1 at „f“ with the hexagon bolts M10x110 and collar nuts M10.<br />

9.) Use bolts M12/nuts M12 of strength class 10.<br />

Use bolts M10/nuts M10 of strength class 10.<br />

Tightening torques:<br />

Bolts M12 - strength class 10.9 ➔ 115 Nm +5%<br />

Bolts M10 - strength class 10.9 ➔ 50 Nm +5%<br />

The standard fixing points on the vehicle specified by the vehicle manufacturer and approved in the General<br />

Certification must be observed.<br />

Electrical system in compliance with German StVZO (Motor Vehicle Safety Standards).<br />

Ensure that the installation dimensions and clearances as per DIN 74 058 are observed.<br />

18