Egg transport systems World-wide in action! - Meller.net

Egg transport systems World-wide in action! - Meller.net

Egg transport systems World-wide in action! - Meller.net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

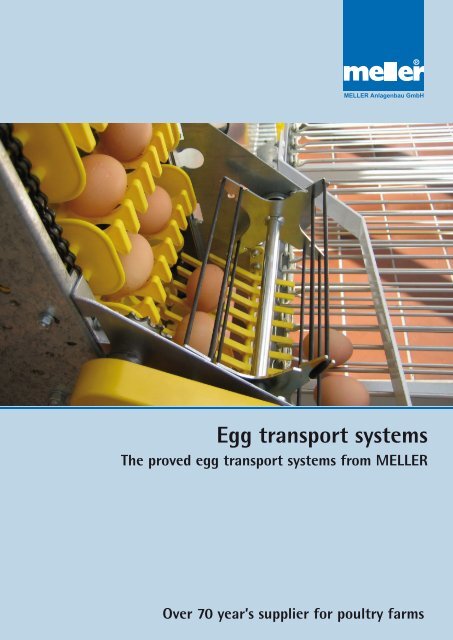

<strong>Egg</strong> <strong>transport</strong> <strong>systems</strong><br />

The proved egg <strong>transport</strong> <strong>systems</strong> from MELLER<br />

Over 70 year’s supplier for poultry farms

<strong>Egg</strong> <strong>transport</strong> <strong>systems</strong> <strong>in</strong> MELLER <strong>in</strong>stallations<br />

MELLER <strong>in</strong>stallations – among others economy and longevity,<br />

quality and cont<strong>in</strong>uously development.<br />

Elevator<br />

The elevator operates without a dos<strong>in</strong>g device, which means, that<br />

up to the egg cross conveyor the eggs only have to be transfered<br />

twice. Due to the larger number of conveyor baskets, a higher<br />

<strong>transport</strong> capacity of max. 16,000 eggs per hour can be reached.<br />

The egg elevator allow the eggs from all levels of the lay<strong>in</strong>g system<br />

to be collected simultaneously. The transfer of the eggs onto<br />

the egg cross conveyor can occur at any height you choose. This<br />

Approved signs:<br />

• A solid construction made of high-grade materials<br />

<strong>in</strong> perfect fabrication<br />

• An elaborated and nearly ma<strong>in</strong>tenance free technique<br />

guarantees a long durability and a high efficiency<br />

• Simultaneously collect<strong>in</strong>g of the eggs <strong>in</strong> all levels to<br />

the same time<br />

• Works with each system caused on the <strong>in</strong>dependence of<br />

the height to transfer the eggs from the elevator onto the<br />

egg cross conveyor.<br />

• High <strong>transport</strong> capacity of max. 16,000 eggs per hour<br />

caused on the optimized design<br />

• Automatic forerun control with time relays<br />

The <strong>Egg</strong> Saver<br />

An egg saver system is also available upon request. <strong>Egg</strong>s roll<strong>in</strong>g<br />

down from cage bottoms are gently reta<strong>in</strong>ed by the egg saver<br />

wires and thus do not roll directly onto the egg collection belts.<br />

Thus, eggs already on the conveyors are not damaged by <strong>in</strong>com<strong>in</strong>g<br />

eggs.<br />

The egg saver wires are raised by compressed air cyl<strong>in</strong>ders at<br />

certa<strong>in</strong> <strong>in</strong>tervals and the eggs roll slowly onto the egg collection<br />

belts. The electrical control unit and the pneumatic system are<br />

<strong>in</strong>cluded <strong>in</strong> the delivery of the egg saver.<br />

<strong>Egg</strong> <strong>transport</strong> <strong>systems</strong><br />

means that the egg cross conveyor does not <strong>in</strong>evitably have to be<br />

<strong>in</strong>stalled on or under the floor, but can be e.g. arranged so that a<br />

passageway is left open.<br />

The egg collector is equipped with two mutually <strong>in</strong>dependent drives,<br />

one of which drives the egg collection belts with<strong>in</strong> the system<br />

(upon request with rpm control/frequency converter). To achieve<br />

higher tractive forces, especially <strong>in</strong> long <strong>systems</strong>, the power take-off<br />

rollers of the lengthwise egg belts are rubber-coated and<br />

equipped with additional pressure rollers.<br />

The other drive runs at a constant speed and serves to drive the<br />

elevators or dos<strong>in</strong>g devices. All drive shafts run <strong>in</strong> ma<strong>in</strong>tenancefree<br />

plastic bear<strong>in</strong>gs.

Lift<br />

One advantage of the lift<strong>in</strong>g system, among others, is that the<br />

eggs must only be transferred once on their journey from the<br />

collection belts to the farm packer or grad<strong>in</strong>g masch<strong>in</strong>e.<br />

It conta<strong>in</strong>s a multi-level conveyor, which means that the collection<br />

belts are driven by coupl<strong>in</strong>gs or one power take-off per<br />

level. The lift<strong>in</strong>g system positions the egg cross conveyor <strong>in</strong> front<br />

of the level <strong>in</strong> need of collection. A brak<strong>in</strong>g geared motor and<br />

Approved signs:<br />

• A solid construction made of high-grade materials <strong>in</strong><br />

perfect fabrication<br />

• An elaborated and nearly ma<strong>in</strong>tenance free technique<br />

guarantees a long durability and a high performance<br />

• Only one transfer from egg belt till farmpacker or<br />

sort<strong>in</strong>g mach<strong>in</strong>e<br />

• Transport of the eggs per each tier<br />

• M<strong>in</strong>imum space requirements<br />

• Automatic switch<strong>in</strong>g from tier to tier<br />

<strong>Egg</strong>-Protection Cord<br />

The <strong>Egg</strong>-Protection Cord is used as protection for the hens, because<br />

the hens like to pick the eggs themselves, respectively eat<br />

them. Due to this reason the <strong>Egg</strong>-Protection Cord is placed above<br />

the <strong>Egg</strong>-Saver. It runs through <strong>in</strong>sulators and is a live wire.<br />

If the hen tries to touch the egg it will get an electric shock.<br />

Because the birds are adaptive they will not try further to eat<br />

the eggs.<br />

limit switch are components of the lift<strong>in</strong>g system, which guarantee<br />

the exact position<strong>in</strong>g of the egg cross conveyor <strong>in</strong> front<br />

of the <strong>in</strong>dividual levels.<br />

Circuit technology ensures that the egg collection belts on one<br />

level can only be operated when the egg cross conveyor is positioned<br />

<strong>in</strong> front of this level. Washout eggs fall through special<br />

egg transfer devices <strong>in</strong>to collection trays.<br />

Further advantages to this system are the m<strong>in</strong>imal space requirements<br />

and an open passageway due to the parked position of<br />

the egg cross conveyor above the batteries.<br />

www.meller.<strong>net</strong> <strong>Egg</strong> <strong>transport</strong> <strong>systems</strong>

<strong>Egg</strong> <strong>transport</strong> <strong>systems</strong><br />

MELLER Anlagenbau GmbH<br />

Postfach 68 - D 49302 Melle<br />

Elf Stücken 25 - D 49324 Melle<br />

Tel: +49 (0) 5422-94 89 0<br />

Fax: +49 (0) 5422-94 89 40<br />

E-Mail: <strong>in</strong>fo@meller.<strong>net</strong><br />

Inter<strong>net</strong>: www.meller.<strong>net</strong><br />

<strong>World</strong>-<strong>wide</strong> <strong>in</strong> <strong>action</strong>!<br />

S<strong>in</strong>ce over 70 years MELLER is an <strong>in</strong>novative and reliable partner <strong>in</strong> the<br />

poultry <strong>in</strong>dustry. The cooperation with our customers is important for us.<br />

Because their success is our success too. MELLER <strong>systems</strong> are successfully<br />

operated <strong>in</strong> more than 25 countries world<strong>wide</strong>. More than 80% of<br />

production is exported.