Metal Samples catalog

Metal Samples catalog

Metal Samples catalog

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

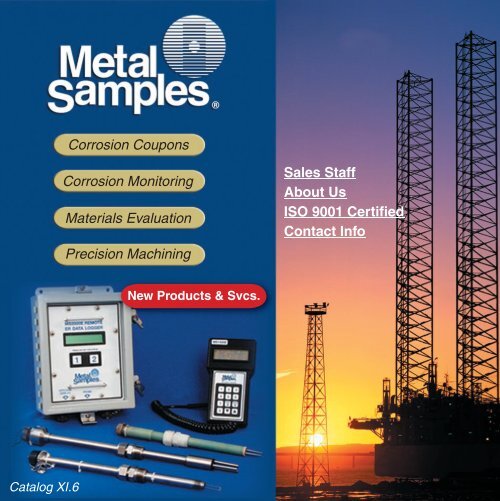

Corrosion Coupons<br />

Corrosion Monitoring<br />

Materials Evaluation<br />

Precision Machining<br />

Sales Staff<br />

About Us<br />

ISO 9001 Certified<br />

Contact Info<br />

New Products & Svcs.<br />

Catalog XI.6

<strong>Metal</strong> <strong>Samples</strong> Company is a division of Alabama Specialty Products, Inc. (ASPI) and works in association<br />

with other divisions of ASPI to provide you with a wide range of products and services.<br />

• Materials evaluation products<br />

• Corrosion monitoring products<br />

• Precision machining services<br />

• Laser cutting & welding services<br />

• Laser systems and equipment<br />

• Specialized laser R&D services<br />

• Maufacturing research<br />

• Medical equipment<br />

For more information on our company divisions, call for a product brochure or visit our corporate web site at:<br />

www.alspi.com

Business Philosophy<br />

<strong>Metal</strong> <strong>Samples</strong>, a division of Alabama Specialty Products, Inc., is committed to superior quality,<br />

quick delivery, fair pricing, and excellent service. With our rapidly-expanding physical plant, stateof-the-art<br />

equipment, ever-broadening product lines, dedicated research, and highly-skilled work<br />

force, we stand ready to meet your specific manufacturing needs.<br />

However, it takes more than buildings, equipment, and personnel to produce excellence; it takes<br />

espirit de corps. That is why our company works energetically as a whole, realizing the significance<br />

of our motto, “May the beauty of the LORD our GOD be upon us and may He establish the work<br />

of our hands.” Psalm 90:17.

About <strong>Metal</strong> <strong>Samples</strong><br />

<strong>Metal</strong> <strong>Samples</strong> specializes in manufacturing<br />

products for corrosion monitoring & materials<br />

evaluation and in providing precision machining<br />

services. Since 1980 we have supplied products<br />

and services to nuclear, medical, aerospace,<br />

chemical processing, water treating, and<br />

petroleum industries around the world.<br />

From the beginning, founder Don Johnson's goal has been to operate this business based<br />

on Christian principles. With blessings from God, <strong>Metal</strong> <strong>Samples</strong> has grown to include 200<br />

employees and continues to develop new products and technologies to meet the growing<br />

needs of our customers.

<strong>Metal</strong> <strong>Samples</strong> Contact Info<br />

Home Office:<br />

P.O. Box 8, 152 <strong>Metal</strong> <strong>Samples</strong> Rd.<br />

Munford, AL 36268<br />

Phone: (256) 358-4202<br />

Fax: (256) 358-4515<br />

E-mail: msc@alspi.com<br />

Web site: www.metalsamples.com<br />

Houston Sales Office:<br />

6327 Teal Mist Lane<br />

Fulshear, TX 77441<br />

Phone: (832) 451-6825

Alabama Specialty Products, Inc. (ASPI)<br />

Executive Staff<br />

Don Johnson<br />

ASPI CEO<br />

James Gray<br />

<strong>Metal</strong> <strong>Samples</strong> President<br />

Brad Finley<br />

Vice President<br />

<strong>Metal</strong> <strong>Samples</strong><br />

Sales & Support Staff<br />

Brenda Smith<br />

Sales Manager<br />

Cindy Maddox<br />

Int’l. Coordinator<br />

Bertha Benjamin<br />

Sales Rep.<br />

Rob Huntley<br />

Sales Rep.<br />

Andrew Abbott<br />

Sales Rep.<br />

Deborah Tinney<br />

Sales Rep.<br />

Ron Weishaar<br />

Sales Mgr. (Houston)

Terms & Delivery Services<br />

• Terms - Net 30 days (subject to credit approval)<br />

• Minimum order inside USA - $100.00<br />

• Minimum order outside USA - $300.00<br />

• Overnight delivery available for many stock items<br />

• Orders outside the USA subject to additional charges<br />

• VISA, MASTERCARD, and AMERICAN<br />

EXPRESS accepted.<br />

(Full terms & conditions at www.metalsamples.com.)<br />

Engineering / Design / CAD<br />

Our CAD department uses the latest in computer-aided drafting and design<br />

technology, including 3-D modeling software.<br />

Our engineering team has experience in corrosion, aerospace, electrical,<br />

mechnical, manufacturing, and materials engineering. These engineering<br />

capabilities, coupled with our machining expertise, allow us to help our<br />

customers find solutions to their specific application needs.<br />

Quality Assurance (ISO 9001)<br />

We emphasize high standards when it comes to the quality of your parts. To ensure the finished product will<br />

meet our customers approval, we maintain advanced training for personnel, procurement of state-of-the-art<br />

inspection equipment, and constant upgrading in our quality control area.<br />

Our quality assurance begins with the receipt of raw materials and is adhered to throughout the manufacturing<br />

process until the final product is shipped. Technicians use high-tech inspection equipment to check the accuracy<br />

of your parts. Our quality assurance program is ISO 9001 certified, guaranteeing the highest quality on all of<br />

your orders.

Corrosion Monitoring<br />

Introduction to Corrosion Monitoring<br />

Corrosion Coupons for Monitoring<br />

Electrical Resistance (ER) Monitoring<br />

Linear Polarization Resistance (LPR) Monitoring<br />

Specialized Monitoring<br />

High Pressure Access Systems<br />

Injection & Sampling Systems<br />

Accessories<br />

Return to Main menu

Introduction to Corrosion Monitoring<br />

What is Corrosion Monitoring<br />

The field of corrosion measurement, control, and prevention covers a very broad spectrum of technical<br />

activities. Within the sphere of corrosion control and prevention, there are technical options such as cathodic<br />

and anodic protection, materials selection, chemical dosing and the application of internal and external<br />

coatings. Corrosion measurement employs a variety of techniques to determine how corrosive the environment<br />

is and at what rate metal loss is being experienced. Corrosion measurement is the quantitative method<br />

by which the effectiveness of corrosion control and prevention techniques can be evaluated and provides the<br />

feedback to enable corrosion control and prevention methods to be optimized.<br />

A wide variety of corrosion measurement techniques exists, including:<br />

Non Destructive Testing<br />

Analytical Chemistry<br />

• Ultrasonic testing<br />

• pH measurement<br />

• Radiography • Dissolved gas (O 2<br />

, CO 2<br />

, H 2<br />

S)<br />

• Thermography • <strong>Metal</strong> ion count (Fe 2+ , Fe 3+ )<br />

• Eddy current/magnetic flux<br />

• Microbiological analysis<br />

• Intelligent pigs<br />

Operational Data<br />

• pH<br />

• Flow rate (velocity)<br />

• Pressure<br />

• Temperature<br />

Fluid Electrochemistry<br />

• Potential measurement<br />

• Potentiostatic measurements<br />

• Potentiodynamic measurements<br />

• A.C. impedance<br />

Corrosion Monitoring<br />

• Weight loss coupons<br />

• Electrical resistance<br />

• Linear polarization<br />

• Hydrogen penetration<br />

• Galvanic current<br />

Some corrosion measurement techniques can be used on-line, constantly exposed to the process stream,<br />

while others provide off-line measurement, such as that determined in a laboratory analysis. Some techniques<br />

give a direct measure of metal loss or corrosion rate, while others are used to infer that a corrosive<br />

environment may exist.<br />

Corrosion monitoring is the practice of measuring the corrosivity of process stream conditions by the use of<br />

“probes” which are inserted into the process stream and which are continuously exposed to the process<br />

stream condition.<br />

Corrosion monitoring “probes” can be mechanical, electrical, or electrochemical devices.

Corrosion monitoring techniques alone provide direct and online measurement of metal loss/corrosion rate in<br />

industrial process systems.<br />

Typically, a corrosion measurement, inspection and maintenance program used in any industrial facility will<br />

incorporate the measurement elements provided by the four combinations of on-line/off-line, direct/indirect<br />

measurements.<br />

• Corrosion Monitoring<br />

• Non Destructive Testing<br />

• Analytical Chemistry<br />

• Operational Data<br />

Direct, On-line<br />

Direct, Off-line<br />

Indirect, Off-line<br />

Indirect, On-line<br />

In a well controlled and coordinated program, data from each source will be used to draw meaningful<br />

conclusions about the operational corrosion rates with the process system and how these are most effectively<br />

minimized.<br />

The Need for Corrosion Monitoring<br />

The rate of corrosion dictates how long any process equipment can be usefully and safely operated. The<br />

measurement of corrosion and the action to remedy high corrosion rates permits the most cost effective<br />

plant operation to be achieved while reducing the life-cycle costs associated with the operation.<br />

Corrosion monitoring techniques can help in several ways:<br />

(1) by providing an early warning that damaging process conditions exist which may result in a corrosioninduced<br />

failure.<br />

(2) by studying the correlation of changes in process parameters and their effect on system corrosivity.<br />

(3) by diagnosing a particular corrosion problem, identifying its cause and the rate controlling parameters,<br />

such as pressure, temperature, pH, flow rate, etc.<br />

(4) by evaluating the effectiveness of a corrosion control/prevention technique such as chemical inhibition<br />

and the determination of optimal applications.<br />

(5) by providing management information relating to the maintenance requirements and ongoing condition<br />

of plant.<br />

Corrosion - 2

Corrosion Monitoring Techniques<br />

A large number of corrosion monitoring techniques exist. The following list details the most common techniques<br />

which are used in industrial applications:<br />

• Corrosion Coupons (weight loss measurements)<br />

• Electrical Resistance (ER)<br />

• Linear Polarization Resistance (LPR)<br />

• Galvanic (ZRA)<br />

• Hydrogen Penetration<br />

• Microbial<br />

• Sand/Erosion<br />

Other techniques do exist, but almost all require some expert operation, or otherwise are not sufficiently<br />

rugged or adaptable to plant applications.<br />

Of the techniques listed above, corrosion coupons, ER, and LPR form the core of industrial corrosion<br />

monitoring systems. The four other techniques are normally found in specialized applications which are<br />

discussed later.<br />

These corrosion monitoring techniques have been successfully applied and are used in an increasing range of<br />

applications because:<br />

• The techniques are easy to understand and implement.<br />

• Equipment reliability has been demonstrated in the field environment over many years of<br />

operational application.<br />

• Results are easy to interpret.<br />

• Measuring equipment can be made intrinsically safe for hazardous area operation.<br />

• Users have experienced significant economic benefit through reduced plant down time and<br />

plant life extension.<br />

Corrosion Coupons (Weight Loss)<br />

The Weight Loss technique is the best known and simplest<br />

of all corrosion monitoring techniques. The method involves<br />

exposing a specimen of material (the coupon) to a<br />

process environment for a given duration, then removing<br />

the specimen for analysis. The basic measurement which is<br />

determined from corrosion coupons is weight loss; the<br />

weight loss taking place over the period of exposure being<br />

expressed as corrosion rate.<br />

The simplicity of the measurement offered by the corrosion coupon is such that the coupon technique forms<br />

the baseline method of measurement in many corrosion monitoring programs.<br />

Corrosion - 3

The technique is extremely versatile, since weight loss coupons can be fabricated from any commercially<br />

available alloy. Also, using appropriate geometric designs, a wide variety of corrosion phenomena may be<br />

studied which includes, but is not limited to:<br />

• Stress-assisted corrosion<br />

• Bimetallic (galvanic) attack<br />

• Differential aeration<br />

• Heat-affected zones<br />

Advantages of weight loss coupons are that:<br />

• The technique is applicable to all environments - gases, liquids, solids/particulate flow.<br />

• Visual inspection can be undertaken.<br />

• Corrosion deposits can be observed and analyzed.<br />

• Weight loss can be readily determined and corrosion rate easily calculated.<br />

• Localized corrosion can be identified and measured.<br />

• Inhibitor performance can be easily assessed.<br />

In a typical monitoring program, coupons are exposed for a 90-day duration before being removed for a<br />

laboratory analysis. This gives basic corrosion rate measurements at a frequency of four times per year. The<br />

weight loss resulting from any single coupon exposure yields the “average” value of corrosion occurring<br />

during that exposure. The disadvantage of the coupon technique is that, if a corrosion upset occurs during<br />

the period of exposure, the coupon alone will not be able to identify the time of occurrence of the upset, and<br />

depending upon the peak value of the upset and its duration, may not even register a statistically significant<br />

increased weight loss.<br />

Therefore, coupon monitoring is most useful in environments where corrosion rates do not significantly<br />

change over long time periods. However, they can provide a useful correlation with other techniques such as<br />

ER and LPR measurements.<br />

Electrical Resistance (ER) Monitoring<br />

ER probes can be thought of as “electronic” corrosion coupons. Like coupons, ER probes provide a basic<br />

measurement of metal loss, but unlike coupons, the value of metal loss can be measured at any time, as<br />

frequently as required, while the probe is in-situ and permanently exposed to the process stream.<br />

In this diagram, a standard ER instrument is connected to a 40<br />

mil wire loop element which has a useful life of 10 mils. The<br />

instrument still reads close to zero because the element is new.<br />

Here the instrument reads around half-scale, indicating that the<br />

element has experienced about 5 mils of metal loss or about half<br />

of its useful life. The instrument’s reading is increasing proportionally<br />

with the resistance of the element, which increases as a<br />

result of metal loss.<br />

Here the instrument reads almost full scale, indicating that the<br />

element has experienced 10 mils of metal loss and requires<br />

replacement.<br />

Corrosion - 4

The ER technique measures the change in Ohmic resistance of a corroding metal element exposed to the<br />

process stream. The action of corrosion on the surface of the element produces a decrease in its crosssectional<br />

area with a corresponding increase in its electrical resistance. The increase in resistance can be<br />

related directly to metal loss and the metal loss as a function of time is by definition the corrosion rate.<br />

Although still a time averaged technique, the response time for ER monitoring is far shorter than that for<br />

weight loss coupons. The graph below shows typical response times.<br />

100<br />

75<br />

50<br />

25<br />

MPY<br />

5<br />

MPY<br />

12<br />

MPY<br />

25<br />

0 2 4 6 8 10 12 14<br />

Time (Days)<br />

ER probes have all the advantages of coupons, plus:<br />

• Direct corrosion rates can be obtained.<br />

• Probe remains installed in-line until operational life has been exhausted.<br />

• They respond quickly to corrosion upsets and can be used to trigger an alarm.<br />

ER probes are available in a variety of element geometries, metallurgies and sensitivities and can be<br />

configured for flush mounting such that pigging operations can take place without the necessity to remove<br />

probes. The range of sensitivities allows the operator to select the most dynamic response consistent with<br />

process requirements.<br />

Linear Polarization Resistance (LPR) Monitoring<br />

The LPR technique is based on complex electro-chemical<br />

theory. For purposes of industrial measurement applications it<br />

is simplified to a very basic concept. In fundamental terms, a<br />

small voltage (or polarization potential) is applied to an<br />

electrode in solution. The current needed to maintain a<br />

specific voltage shift (typically 10 mV) is directly related to<br />

the corrosion on the surface of the electrode in the solution.<br />

By measuring the current, a corrosion rate can be derived.<br />

The advantage of the LPR technique is that the measurement<br />

of corrosion rate is made instantaneously. This is a more powerful tool than either coupons or ER where the<br />

fundamental measurement is metal loss and where some period of exposure is required to determine<br />

corrosion rate. The disadvantage to the LPR<br />

Corrosion - 5

technique is that it can only be successfully performed in relatively clean aqueous electrolytic environments.<br />

LPR will not work in gases or water/oil emulsions where fouling of the electrodes will prevent measurements<br />

being made.<br />

Galvanic Monitoring<br />

The galvanic monitoring technique, also known as Zero Resistance Ammetry (ZRA) is another electrochemical<br />

measuring technique. With ZRA probes, two electrodes of dissimilar metals are exposed to the<br />

process fluid. When immersed in solution, a natural voltage (potential) difference exits between the electrodes.<br />

The current generated due to this potential difference relates to the rate of corrosion which is occurring<br />

on the more active of the electrode couple.<br />

Galvanic monitoring is applicable to the following electrode couples:<br />

• Bimetallic corrosion<br />

• Crevice and pitting attack<br />

• Corrosion assisted cracking<br />

• Corrosion by highly oxidizing species<br />

• Weld decay<br />

Galvanic current measurement has found its widest applications in water injection systems where dissolved<br />

oxygen concentrations are a primary concern. Oxygen leaking into such systems greatly increases galvanic<br />

currents and thus the corrosion rate of steel process components. Galvanic monitoring systems are used to<br />

provide an indication that oxygen may be invading injection waters through leaking gaskets or deaeration<br />

systems.<br />

Specialized Monitoring<br />

Biological Monitoring<br />

Biological monitoring and analysis generally seeks to identify the presence<br />

of Sulphate Reducing Bacteria - SRB’s. This is a class of anaerobic<br />

bacteria which consume sulphate from the process stream and generate<br />

sulphuric acid, a corrosive which attacks production plant materials.<br />

Sand / Erosion Monitoring<br />

These are devices which are designed to measure erosion in a flowing<br />

system. They find wide application in oil/gas production systems where particulate matter is present.<br />

Hydrogen Penetration Monitoring<br />

In acidic process environments, hydrogen is a by-product of the corrosion reaction. Hydrogen generated in<br />

such a reaction can be absorbed by steel particularly when traces of sulphide or cyanide are present. This<br />

may lead to hydrogen induced failure by one or more of several mechanisms. The concept of hydrogen<br />

probes is to detect the amount of hydrogen permeating through the steel by mechanical or electrochemical<br />

measurement and to use this as a qualitative indication of corrosion rate.<br />

Corrosion - 6

Instrumentation<br />

There exists a variety of instrument options associated with the various corrosion monitoring techniques.<br />

Three classifications are:<br />

• Portable Meters and Data Loggers<br />

• Field-Mounted Data Loggers<br />

• Field-Mounted Transmitters<br />

In some applications such as those experienced in oil/gas production and refining, instrumentation is required<br />

to be certified for use in “hazardous areas”. For portable instruments this is most often achieved by having<br />

the equipment certified as “intrinsically safe” by a recognized authority such as BASEEFA (U.K.), U.L.<br />

(U.S.A.), ITS (U.S.A.), or CENELEC (Europe). For hardwired continuous monitoring electronics, isolation<br />

barriers can be used to ensure that, in the event of a fault condition, insufficient energy is transmitted to<br />

the hazardous field area for an explosive spark to be produced.<br />

Probe Fitting Styles<br />

There are two fundamental fitting styles for corrosion probes: fixed and removable under pressure.<br />

Fixed styles of probes/sensors have typically a threaded or flanged attachment to the process plant. For<br />

fixed styles of sensors, removal can only be accomplished during system shut down or by isolation and<br />

depressurization of the sensor location.<br />

From time to time, corrosion coupons and probes require removal and replacement. It is sometimes more<br />

convenient to be able to remove and install sensors while the process system is operational. To facilitate this,<br />

there are two distinct systems which permit removal/installation under pressure.<br />

In refinery and process plant environments where pressures are normally less than 1500 psi, a Retractable<br />

System is used. This consists of a packing gland (stuffing box) and valve arrangement. For environments<br />

such as those experienced in oil/gas production where pressures of several thousand psi are experienced, a<br />

special High Pressure Access System is used. This permits the safe and easy installation/removal of corrosion<br />

monitoring devices at working pressures up to 3600 psi.<br />

Applications of Corrosion Monitoring Techniques<br />

Corrosion monitoring is typically used in the following situations:<br />

• Where risks are high - high pressure, high temperature, flammable, explosive, toxic processes.<br />

• Where process upsets can cause high corrosivity.<br />

• Where changes in operating conditions can cause significant changes in corrosion rate.<br />

Corrosion - 7

• Where corrosion inhibitors are in use.<br />

• In batch processes, where corrosive constituents are concentrated due to repeated cycling.<br />

• Where process feedstock is changed.<br />

• Where plant output or operating parameters are changed from design specifications.<br />

• In the evaluation of corrosion behavior of various alloys.<br />

• Where induced potential shifts are used to protect systems and/or structures.<br />

• Where product contamination due to corrosion is a vital concern.<br />

Corrosion monitoring may be used in virtually any industry where corrosion prevention is a primary<br />

requirement. Some examples of industries and specific areas of interest include, but are not limited to:<br />

Oil/Gas Production<br />

• Flowlines<br />

• Gathering Systems<br />

• Transport Pipelines<br />

• Water Injection Facilities<br />

• Vessels<br />

• Processing<br />

• Water Systems<br />

• Chemical Injection Systems<br />

• Drilling Mud Systems<br />

• Water Wash Systems<br />

• Desalters<br />

Utilities<br />

• Cooling Systems<br />

• Effluent Systems<br />

• Make-Up Water Systems<br />

• Boiler Water Systems<br />

Refining<br />

• Crude Overheads<br />

• Visbreakers<br />

• Vacuum Towers<br />

• Sour Water Strippers<br />

• Amine Systems<br />

• Cooling Systems<br />

Pulp and Paper<br />

• Digesters<br />

• White Liquor<br />

• Boiler Systems<br />

Petrochemicals/Chemicals/Processing<br />

• Process Systems<br />

• Cooling Systems<br />

In any corrosion monitoring system, it is common to find two or more of the techniques combined to provide<br />

a wide base for data gathering. The exact techniques which can be used depend on the actual process<br />

fluid, alloy system, and operating parameters.<br />

Corrosion monitoring offers an answer to the question of whether more corrosion is occurring today as<br />

compared to yesterday. Using this information it is possible to qualify the cause of corrosion and quantify its<br />

effect. Corrosion monitoring remains a valuable weapon in the fight against corrosion, thereby providing<br />

substantial economic benefit to the user.<br />

<strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems<br />

A Division of Alabama Specialty Products, Inc.<br />

152 <strong>Metal</strong> <strong>Samples</strong> Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515<br />

E-mail: msc@alspi.com Internet: www.metalsamples.com<br />

Houston Office: 6327 Teal Mist Lane, Fulshear, TX 77441 Phone: (832) 451-6825

Corrosion Coupons<br />

Introduction to Corrosion Coupons<br />

and Weight Loss Analysis<br />

Standard Coupons<br />

Coupon Ordering and Options Available<br />

Welded Coupons<br />

Stressed Coupons<br />

Elastomeric Coupons<br />

Test Racks<br />

Coupon Holders<br />

Easy Tool Retracting System<br />

Length Calculation & Accessories for<br />

Retractable Coupon Holders<br />

Corrosion Coupons for<br />

High Pressure Access Systems<br />

Coupon Holders for<br />

High Pressure Access Systems<br />

Bypass Piping Systems<br />

Post Exposure Coupon Analysis<br />

Coupon Storage (VCI Bags)<br />

Alloys List<br />

Alloys Listed by Trademark<br />

Articles on Coupon Testing<br />

Return to Main Menu

Corrosion Coupons and Weight Loss Analysis<br />

Introduction<br />

The simplest, and longest-established, method of estimating corrosion losses in plant<br />

and equipment is weight loss analysis. A weighed sample (coupon) of the metal or<br />

alloy under consideration is introduced into the process, and later removed after a<br />

reasonable time interval. The coupon is then cleaned of all corrosion product and is<br />

reweighed. The weight loss is converted to a corrosion rate (CR) or a metal loss<br />

(ML), as follows:<br />

Corrosion<br />

Rate (CR)<br />

=<br />

Weight loss (g) * K<br />

Alloy Density (g/cm 3 ) * Exposed Area (A) * Exposure Time (hr)<br />

The constant can be varied to calculate the corrosion rate in various units:<br />

Desired Corrosion Rate Unit (CR) Area Unit (A) K-Factor<br />

mils/year (mpy) in 2 5.34 x 10 5<br />

mils/year (mpy) cm 2 3.45 x 10 6<br />

millimeters/year (mmy) cm 2 8.75 x 10 4<br />

<strong>Metal</strong><br />

Loss (ML)<br />

=<br />

Weight loss (g) * K<br />

Alloy Density (g/cm 3 ) * Exposed Area (A)<br />

Desired <strong>Metal</strong> Loss Unit (ML) Area Unit (A) K-Factor<br />

mils in 2 61.02<br />

mils cm 2 393.7<br />

millimeters cm 2 10.0<br />

The technique requires no complex equipment or procedures, merely an appropriately shaped coupon, a carrier<br />

for the coupon (coupon holder), and a reliable means of removing corrosion product without disruption of the<br />

metal substrate. Weight loss measurement is still the most widely used means of determining corrosion loss,<br />

despite being the oldest method currently in use.<br />

Weight loss determination has a number of attractive features that account for its sustained popularity:<br />

• Simple - No sophisticated instrumentation is required to obtain a result.<br />

• Direct - A direct measurement is obtained, with no theoretical assumptions or<br />

approximations.<br />

• Versatile - It is applicable to all corrosive environments, and gives information on<br />

all forms of corrosion.<br />

The method is commonly used as a calibration standard for other means of corrosion monitoring, such as Linear<br />

Polarization and Electrical Resistance. In instances where slow response and averaged data are acceptable,<br />

weight loss monitoring is the preferred technique.

Coupon Preparation and Cleaning<br />

The choice of technique for initial preparation of the coupon surface, and for cleaning the coupon after use, is<br />

critical in obtaining useful data. Both the relevance and reproducibility of weight loss data are highly sensitive to<br />

the inherent suitability of these techniques, and to the care with which they are executed.<br />

Surface finishing methods vary across a broad range for specific<br />

applications. Blasting with glass bead, sand, or other aggregate can<br />

provide an acceptable finish for some applications. Sanding with<br />

abrasive belts, or surface or double disc grinding with abrasive stones<br />

also provides an excellent surface for evaluation.<br />

Coupon after being exposed<br />

to corrosive environment.<br />

Cleaning of specimens before weighing and exposure is critical to remove any contaminants that could affect test<br />

results.<br />

Reference should be made to NACE Recommended Practice RP-0775 and ASTM G-1 & G-4 for further<br />

detail on surface finishing and cleaning of weight-loss coupons.<br />

Coupon Position and Orientation<br />

Irrespective of the degree of care exercised in the surface preparation of coupons, many uncontrollable factors<br />

(e.g. microstructural defects) can reduce the accuracy of weight loss determinations. Therefore, using duplicate<br />

(Figure 1) or multi-replicate (Figure 2) coupon samples is considered good practice.<br />

Coupon orientation must be consistent in order to make different data sets comparable. Generally, an orientation<br />

parallel to the process flow is preferable since this more nearly reflects the true condition experienced by the<br />

vessel wall (Figure 1). <strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems MH coupon holders have an automatic<br />

flow alignment feature. All other holders are marked on the top side with flow direction for manual alignment.<br />

Positioning is another critical factor in obtaining relevant information. For example, a multi-phase product may<br />

produce layered flow, giving rise to corrosion rates that vary with depth in the process stream. Such situations<br />

can be monitored with a ladder-strip coupon holder (Figure 2).<br />

Flow<br />

Figure 1. Preferred Flow Direction<br />

Figure 2. Ladder Strip Coupon Holder

Possibly the most common issue in coupon positioning arises from the fact that a true representation of the<br />

corrosion experienced by the pipe/vessel can only be established when the weight loss coupon is in the plane of<br />

the vessel/pipe wall. Only in this position can the coupon experience the same flow regime as the pipe surface<br />

being monitored. In response to this situation, the use of flush-disc coupons has become widespread (Figure 3).<br />

The general issue of coupon orientation and positioning in relation to flow regime, plant geometry, and process<br />

fluid is complex and tends to be specific to each application. However, the most common coupon configurations<br />

have been discussed above.<br />

Figure 3. Flush Disc Coupon Holder in High Pressure Access Fitting<br />

Coupon Holders<br />

Specific design of coupon holders incorporates two basic factors:<br />

• Number, style, and configuration of coupons<br />

• System entry method<br />

Fixed (Pipe Plug) Coupon Holders<br />

The simplest system entry design for coupon holders is the fixed or pipe plug coupon holder (Figure 4). This<br />

type of coupon holder is normally offered on a ¾", 1", or 2" NPT pipe-plug. The size of the plug to be used is<br />

the limiting factor as to the coupon configuration that can be used. These coupon holders are usually constructed<br />

in AISI 316L stainless steel, have a pressure rating of 3000 psi, and a temperature rating of 450°F/232°C. This<br />

design of coupon holder is recommended for use in a by-pass loop which can be isolated, or in systems having<br />

frequent and regular shut-down, since system depressurization is required during insertion and removal.<br />

Figure 4. Fixed (Pipe Plug) Coupon Holder

Retractable Coupon Holders<br />

A design that is commonly used in the refining and petrochemical industry is the retractable type coupon holder<br />

as shown in Figure 5. This coupon holder design employs a packing gland that allows insertion and removal,<br />

through a ball-valve, without system depressurization. A safety cable and safety nut are also provided to prevent<br />

blowout. Retractable coupon holders can be used up to 1500 psi and 500°F (260°C), and are constructed of<br />

AISI 316L stainless steel. Normally, a 1" FNPT packing gland is used in conjunction with either a 1", or a 1½"<br />

full port ball valve, depending on the type of coupon configuration chosen. (See the RT4000 sheet for more<br />

information.)<br />

Figure 5. Retractable Coupon Holder<br />

Retrievable Coupon Holders<br />

The oil and gas production industry generally employs retrievable coupon holders that operate with high pressure<br />

access systems. This will allow insertion/removal under pressures up to 3600 psi. <strong>Metal</strong> <strong>Samples</strong> Corrosion<br />

Monitoring Systems supplies both generic (HP) and proprietary (MH) coupon holders. (See Coupon<br />

Holders for High Pressure Access Systems.)<br />

The retrievable coupon holder is installed on to the solid plug. The assembly can then be inserted or removed<br />

from the system using a special service valve and retrieval tool.<br />

Retrievable coupon holders are generally constructed in AISI 316L stainless steel to meet the requirements of<br />

NACE standard MR-0175 for sour service use. These are available for all standard coupon configurations.<br />

Retrievable, retractable, and pipe plug style coupon holders cover the needs of most industries and applications.<br />

However, the requirement for special coupon holder designs is significant, and <strong>Metal</strong> <strong>Samples</strong> Corrosion<br />

Monitoring Systems has the facility to design and build coupon holders to any customer-supplied specification.<br />

<strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems<br />

A Division of Alabama Specialty Products, Inc.<br />

152 <strong>Metal</strong> <strong>Samples</strong> Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515<br />

E-mail: msc@alspi.com Internet: www.metalsamples.com<br />

Houston Office: 6327 Teal Mist Lane, Fulshear, TX 77441 Phone: (832) 451-6825

Corrosion Coupons<br />

Accurate monitoring of corrosion rates in any environment is<br />

critical when viewed in terms of the maintenance and repair costs<br />

associated with corrosion and material failure. Test coupons provide<br />

an inexpensive means of on-line monitoring that will allow<br />

you to effectively measure the corrosivity within your system. By<br />

observing the mils-per-year corrosion rate of an exposed coupon,<br />

valuable information can be provided regarding the material’s life expectancy.<br />

<strong>Metal</strong> <strong>Samples</strong> can make coupons in any size, shape, or material you need. Coupons can be stenciled with alloy<br />

and sequence numbers for proper identification. Mill test reports, identifying element compositions of materials<br />

used, are provided on all orders. The following coupons are four of the most commonly used in corrosion<br />

testing.<br />

P/N CO100<br />

P/N CO131<br />

Shape<br />

Finish<br />

Identification<br />

Surface Area<br />

Rectangular<br />

Double disc or glass bead<br />

Stenciled (alloy, sequence)<br />

3.38 in 2<br />

Shape<br />

Finish<br />

Identification<br />

Surface Area<br />

Rectangular<br />

120 grit, glass bead, or mill<br />

Stenciled (alloy, heat no., sequence)<br />

3.47 in 2<br />

P/N CO146<br />

P/N CO220<br />

Shape<br />

Finish<br />

Identification<br />

Surface Area<br />

Rectangular<br />

Shape<br />

Glass bead or mill<br />

Finish<br />

Stenciled (alloy, sequence)<br />

Identification<br />

4.26 in 2 Surface Area<br />

Circular<br />

120 grit, glass bead, or mill<br />

Stenciled (alloy, sequence)<br />

2.72 in 2<br />

Finishes<br />

• Mill - finished as produced from mill.<br />

• Glass Bead - blasted with fine glass beads to remove mill scale.<br />

• 120 Grit - fine finish using a 120 grit belt. Commonly used in corrosion tests, such as pitting studies, where<br />

smooth surface finish is desired. Finishes up to 600 grit (extremely fine) can be provided.<br />

• Double Disc Ground - extra fine finish using an abrasive disc that leaves minimal residue. Excellent for studies<br />

where surface finish is critical. Can produce 16-32 RMS finishes on common steels and 8 RMS on carbide steels.

Coupon Ordering and Services Available<br />

When placing your order for coupons, be ready to provide the sales person with information regarding the type of<br />

material you are testing, the size coupons required, surface finish desired, and if applicable, mounting hole size and<br />

location. The following options are available:<br />

• Manufacturing on time and material basis<br />

• <strong>Samples</strong> mounted on test racks and ready<br />

for installation<br />

• Preweighing - coupons are cleaned, preweighed<br />

on an electronic scale, and individually packaged<br />

• Weight log charts provided on computer disk<br />

• Non-standard coupons<br />

• Coupon measuring<br />

• Heat-treating, sensitizing, hot dip galvanizing<br />

• Manufacturing from your material if requested<br />

• Coupons made to specific requirements for<br />

mounting hole locations, coupon welding,<br />

stressing, and packaging<br />

• Plating - nickel, nickel cadmium, cadmium,<br />

chrome, silver, gold, and others upon request<br />

• Electro-polishing, hard facing<br />

• Non-metallic coatings<br />

• Anodizing and alonizing<br />

Standard Coupons<br />

Flat Coupons<br />

P/N Size Hole Hole Location<br />

Area<br />

Sq. In.<br />

CO100 1/2" x 3" x 1/16" 3/16" 1/4" fr. end 3.38<br />

CO101 1" x 2" x 1/16" 3/16" 1/4" fr. end 4.32<br />

CO102 1/2" x 3" x 1/16" 9/64" 1/8" fr. end 3.41<br />

CO103 1/2" x 3" x 1/16" 1/4" 1/4" fr. end 3.34<br />

CO104 1/2" x 3" x 1/16" (2) 1/4" 1/2" fr. ea. end 3.24<br />

CO105 1/2" x 3" x 1/16" 3/16" 1/2" fr. end 3.38<br />

CO106 1/2" x 3" x 1/16" 1/4" 1/2" fr. end 3.34<br />

CO115 1/2" x 3" x 1/16" 1/4" 1/4" fr. end<br />

CO117 3/8" x 3" x 1/16" 9/64" 1/8" fr. end 2.64<br />

CO118 1/2" x 3" x 1/16" (2) 1/4" 1/4" & 3/4" end 3.24<br />

CO120 3/8" x 3" x 1/16" (2) 1/4" 1/4" & 3/4" end 2.48<br />

The coupons listed above are made from a variety of materials<br />

(see Alloys list).<br />

Cylindrical Coupons<br />

Area<br />

P/N Size Thread Slot Sq. In.<br />

ES200 1/4" Ø x 2 1/2" 1/4"-20 x 3/8" 1/16" 1.96<br />

Scale coupons (or deposition coupons) provide a<br />

qualitative measure of relative deposition rates in<br />

industrial water and manufacturing process systems.<br />

P/N CO115 (flat)<br />

P/N ES209<br />

(cylindrical)<br />

Mesh bio film coupons are used for quantification<br />

or identification of microorganisms.<br />

P/N COJ36<br />

ES201 1/4" Ø x 2" 1/4"-20 x 3/8" 1/16" 1.57<br />

ES202 1/4" Ø x 3" 1/4"-20 x 3/8" 1/16" 2.45<br />

ES204 1/4" Ø x 1 1/2" 1/4"-20 x 3/8" 1/16" 1.18<br />

ES209* 1/4" Ø x 3" 1/4"-20 x 3/8" 1/16"<br />

* ES209 has five 1/8" diameter scale holes.

Coupon Holders<br />

Fixed (Pipe Plug) Coupon Holders<br />

<strong>Metal</strong> <strong>Samples</strong> carries a variety of standard pipe plug coupon holders for flat and cylindrical specimens. We can<br />

design and make these assemblies to meet your specifications for size and material requirements.<br />

Pipe Plug Assemblies for Flat Coupons<br />

P/N<br />

Plug Size<br />

3" (Std.)<br />

Stem<br />

Used with<br />

Coupon P/N<br />

RC12E*100036 3/4" NPT Nylon CO102, CO117<br />

RC13E*100036 1" NPT Nylon CO102, CO117<br />

RC12Q*100036 3/4" NPT Teflon ® CO102, CO117<br />

RC13Q*100066 1" NPT Teflon ® CO102, CO117<br />

RC12E*010036 3/4" NPT Nylon CO100, CO103, CO115<br />

RC13E*010036 1" NPT Nylon CO100, CO103, CO115<br />

RC12Q*010030 3/4" NPT Teflon ® CO100, CO103, CO115<br />

RC13Q*010026 1" NPT Teflon ® CO100, CO103, CO115<br />

RC12E*030036 3/4" NPT Nylon CO118, CO120<br />

RC13E*030036 1" NPT Nylon CO118, CO120<br />

RC12Q*030036 3/4" NPT Teflon ® CO118, CO120<br />

RC13Q*030035 1" NPT Teflon ® CO118, CO120<br />

RC12E*090036 3/4" NPT Nylon CO105, CO106<br />

RC13E*090036 1" NPT Nylon CO105, CO106<br />

RC12Q*090036 3/4" NPT Teflon ® CO105, CO106<br />

RC13Q*090036 1" NPT Teflon ® CO105, CO106<br />

RC11E*010036 1/2" NPT Nylon CO100, CO103, CO115<br />

* Add "3" to part number for Carbon Steel or "C" for PVC plug.<br />

(Example: Carbon Steel 3/4" pipe plug Nylon stem = RC12E3100036.)<br />

Pipe Plug Assemblies for Cylindrical Coupons<br />

P/N Carbon Steel Plug Insert # of Stems<br />

PA2080413709 2" NPT Nylon 8<br />

PA2080413783 2" NPT Teflon ® 8<br />

RC11Q3040000 1/2" NPT Teflon ® 1<br />

RC12Q3040000 3/4" NPT Teflon ® 1<br />

RC13Q3040000 1" NPT Teflon ® 1<br />

All of these holders are used with ES2 series coupons.<br />

Bypass Piping Systems<br />

We provide conventional or custom-designed bypass systems<br />

for on-line corrosion monitoring. Commonly used in the industrial<br />

water treatment industry to determine the corrosive properties<br />

of potable or cooling water, these systems are available in<br />

PVC, carbon and stainless steels, and other materials.<br />

Bypass systems are easily installed to your existing piping.<br />

Normally, all you need is a 1" NPT male fitting on which to<br />

attach the bypass. Standard bypass systems come equipped with<br />

4 pipe plug assemblies, 4 pre-weighed mild steel coupons, and<br />

a 5-gpm flow control valve.

Adjustable Coupon Holders<br />

Low Pressure or Hand Insertable systems can be used for pressures<br />

up to 125 psi. This assembly is commonly used in the water treating<br />

industry for coupon insertion through a full port valve. An example<br />

of this is in a municipal water pumping station, where leakage during<br />

withdrawal of the test coupon would not be critical. See the SR3000<br />

for more detials.<br />

Retractable Coupon Holders<br />

Packing Gland systems are used in more demanding environments,<br />

where ratings up to 1,500 psi are required and leakage is prohibited.<br />

These systems do not require line (process) shutdown to insert or<br />

withdraw coupons. The assembly is used for coupon insertion through at<br />

least a 1" full port valve. A safety chain is provided to prevent accidental<br />

ejection. See the RT4000 for more details. Also see Length Calculation<br />

and Accessories.<br />

Retrievable Coupon Holders<br />

These coupon holders are used with High Pressure Access Systems where<br />

pressure ratings up to 3,600 psi are required. See HC Series Coupon Holders<br />

for more information.<br />

Post Exposure Coupon Analysis<br />

<strong>Metal</strong> <strong>Samples</strong> offers post exposure coupon analysis. Our trained technicians<br />

will perform weight loss analysis and determine mils per year<br />

(MPY) corrosion rates of your exposed test samples. We are in adherence<br />

to ASTM-G1 specifications for cleaning and analyzing coupons.<br />

When using this service, ensure that initial coupon weights, exposure<br />

dates, and locations are recorded for each<br />

sample. This information can be recorded<br />

on the front of a VCI coupon storage bag.<br />

Optional services include pit depth measurement and photos of the coupons before<br />

and after analysis. For additional information on post exposure coupon analysis<br />

see "Coupon Evaluation after Exposure".

Coupon Storage Bags<br />

Vapor corrosion inhibitor (VCI) bags are excellent for storage of ferrous<br />

and non-ferrous coupons. With VCI bags, coupons can be protected from<br />

corrosion for up to one year when stored under the proper environmental<br />

conditions. Pertinent data regarding coupon exposure can be recorded in<br />

the appropriate spaces on the front of the bag. Ask for P/N BG5001 when<br />

ordering these bags.<br />

Welded Coupons<br />

Corrosion rates can vary between welded and non-welded metals, therefore it is advisable to study the behavior<br />

of both conditions. Studies involve examination of the parent material, the heat-affected zone, the weld metal,<br />

and the interfaces between all metals involved. The surface effects produced by welding, heat-tint formation or<br />

oxidation, fluxing action of slag, and the deliquescence of slag can be important factors in the corrosion behavior<br />

of metals.<br />

Ideally, the coupon used should be the same thickness and welded with the same<br />

welding process as the material used in the production equipment. Usually this is not<br />

practical so a representative sample must be studied.<br />

Typical welding techniques used are Shielded <strong>Metal</strong> Arc (SMAW), Gas Tungsten<br />

Arc (GTAW), and Gas <strong>Metal</strong> Arc (GMAW). Specimens are ground smooth after<br />

welding, unless otherwise specified, so as to provide a uniform surface for microscopic<br />

investigation.<br />

Welded coupons can be prepared with or without the use of filler metal.<br />

The autogenous weld is prepared without the use of filler metal. This<br />

type of weld is the most economical method. Autogenous welds are<br />

commonly used to evaluate corrosion rates of welded materials and the<br />

usage of these materials in corrosive environments. An autogenous weld<br />

is produced by GTAW and can be used to test material weldability and<br />

gas shield usage, and to set welding parameters.<br />

Autogenous Weld Coupon<br />

Identification<br />

1/8"<br />

1"<br />

2"<br />

.375 thru<br />

Autogenous weld<br />

3/4"<br />

.375"<br />

3/8"<br />

Notes:<br />

1. 120 grit standard finish unless otherwise specified.<br />

2. 1/8" nominal thickness.<br />

3. Standard weld is autogenous weld across end (A.W.A.E.).<br />

Sanded after weld.

Stressed Coupons<br />

Stress corrosion cracking occurs when tensile stress combines with a corrosive environment to attack a material.<br />

Testing for this type of corrosion is critical in storage tanks, pressure piping, and vessels commonly used<br />

in chemical processing plants and petrochemical refineries. <strong>Metal</strong> <strong>Samples</strong> can make your stressed samples in<br />

accordance with all ASTM standards including G30, G38, G39, and G58 or to your custom specifications.<br />

P/N CS502<br />

ASTM G30<br />

P/N CS502W (Welded)<br />

ASTM G58<br />

1/2"<br />

Approximate<br />

stenciling<br />

location<br />

(if required)<br />

1/2"<br />

R (Radius)<br />

3/8" D (Hole Diameter)<br />

Centrally Located<br />

X<br />

W<br />

3/4"<br />

M<br />

L 5"<br />

T 1/16"<br />

P/N TF2445<br />

ASTM G39<br />

P/N TF2404 Stressing Frame<br />

For use with P/N TF2445<br />

P/N CO303<br />

Twist Specimen<br />

P/N CS500<br />

Tear Drop<br />

P/N CS513<br />

"C" Ring - ASTM G38

Elastomeric Coupons<br />

<strong>Metal</strong> <strong>Samples</strong> in conjunction with International Seal Co.,<br />

Inc., and DuPont Dow Elastomers offers a selection of<br />

elastomeric coupons. These coupons are used for assistance<br />

in effectively selecting materials for elastomeric testing and<br />

applications.<br />

Fluoro and Perfluoro elastomer based materials<br />

Compound<br />

V75<br />

V75BR<br />

V121<br />

V176<br />

V115<br />

V141<br />

CV75<br />

PF75<br />

Kalrez<br />

4079<br />

Descriptio n<br />

®<br />

75<br />

Durometer General Purpose black Vito n "A" based compoun d<br />

®<br />

75<br />

Durometer General Purpose brown Vito n "A" based compoun d<br />

®<br />

75<br />

Durometer improved chemical resistant Vito n "B" based compoun d<br />

®<br />

75<br />

Durometer lead free acid resistant Vito n "B"<br />

®<br />

75<br />

Durometer improved low temperature Vito n "GLT" based compoun d<br />

®<br />

75<br />

Durometer excellent chemical resistant Vito n "F" based compoun d<br />

®<br />

75<br />

Durometer "Super Chemical" resistant Vito n<br />

75 Durometer "Ultimate Chemical"<br />

temperatures up to 500°F<br />

75 Durometer "Ultimate Chemical"<br />

temperatures up to 600°F<br />

resistant Perfluoro material for<br />

resistant Perfluoro material for<br />

Ethylene Propylene elastomeric based materials<br />

E425<br />

70 Durometer high performance peroxide cured EPDM compoun d<br />

Meets ASTM D2000 4CA 715, A25, E35, C32, F19<br />

E429<br />

70 Durometer EPDM compound that meets ANSI/NSF 61<br />

Nitrile elastomer based material<br />

N470<br />

70 Durometer low compression set nitrile compoun d<br />

Meets ASTM D2000 3CH 720, A25, B14, EO16, EO36<br />

N442<br />

70 Durometer NBR compound that meets ANSI/NSF 61<br />

Viton® is a registered trademark of DuPont Dow Elastomers.

Test Racks<br />

<strong>Metal</strong> <strong>Samples</strong> offers test racks used to mount<br />

coupons and secure them directly to operating<br />

equipment or within a process system. Test racks<br />

make it easy to evaluate how corrosion would<br />

effect differing alloys and material finishes under<br />

identical conditions. Rack usage helps eliminate<br />

coupon loss which might occur if samples were<br />

individually placed in a process flow.<br />

Racks can be fabricated to meet your requirements for material and size. Typical racks are flat bar racks, spool<br />

racks, and pipeline insertion racks. Other racks include angle bar racks and outdoor exposure racks. A variety of<br />

insulators, washers, and spacers used to isolate coupons can also be ordered separately.<br />

Guidelines for Supporting Specimens<br />

Corrosive behavior of materials subjected to immersion, partial<br />

immersion, or vapor phase can have great variance. For this<br />

reason, specimens to be tested should be properly positioned.<br />

There are several important points to be considered when<br />

supporting specimens for exposure:<br />

Pipeline<br />

Insertion Rack<br />

• Each specimen location should be identified by sketch<br />

and recorded.<br />

• The corrosive media should have access to the coupons.<br />

• The test rack should have adequate corrosion resistance<br />

to endure the test.<br />

• Specimens should be electrically isolated from other<br />

metals unless galvanic effects are being studied.<br />

• Specimens should be located in easily accessible areas.<br />

Spool Rack<br />

Flat Bar Rack

Insulators, Washers, & Spacers<br />

<strong>Metal</strong> <strong>Samples</strong> makes a variety of insulators, washers, and spacers used to isolate test specimens. We also make<br />

insulator kits (P/N KR5102) that contain an assortment of washers, screws, nuts, and stems. These kits are designed<br />

for field use when a variety of insulators are needed. The chart shown here is a general guide to material<br />

applications. Call for recommendations on use in hazardous or severe environments.<br />

Material vs. Environment<br />

Material<br />

Acids Alkalies Organic<br />

Water<br />

Absorption<br />

Oxygen<br />

and High Ionizing<br />

Temperature<br />

Resistance<br />

Weak Strong Weak Strong Solvents % 24 hrs. Ozone Vacuum Radiation High Low<br />

R = Resistance A = Attacked SA = Slight Attack A-O = Attacked by Oxidizing Acids G = Good F = Fair P = Poor L = Little Change<br />

Tensile<br />

Strength<br />

lb/in<br />

Fluorocarbons<br />

TFE Inert Inert Inert Inert Inert 0.0 Inert - P 550 G-275 2,500<br />

Nylon G A R R R 1.5 SA - F 300 G-70 10,000<br />

Polyethylene<br />

(low density) R A-O R R G 0.15 A F F 140 G-80 2,000<br />

Polyethylene<br />

(high density) R A-O R R G 0.1 A F G 160 G-100 4,000<br />

Polypropylene R A-O R R R 0.01 A F G 300 P 5,000<br />

Rigid polyvinyl<br />

chloride R R R R A 0.10 R - P 150 P 6,000<br />

Phenolics SA A SA A SA 0.6 - - G 400 L 7,500<br />

Zirconia<br />

ceramics R R R R R 0.0 R - - - - -<br />

Alumina<br />

ceramics R R R R R 0.0 R - - 3180 - -<br />

Rod Insulators<br />

Crevice Washers<br />

Material P/N OD (inches) ID (inches)<br />

Teflon ® 04783004370093 .437 .250<br />

04783004370031 .437 .375<br />

04783002180015 .218 .188<br />

04783002960025 .296 .250<br />

04783003750062 .375 .250<br />

04783004060078 .406 .250<br />

04783005000062 .500 .375<br />

04783006250125 .625 .375<br />

04783006250078 .625 .470<br />

04783008750162 .875 .550<br />

Contact our sales department for the availability of insulators, washers, and spacers not listed.<br />

Dimensions (inches)<br />

Material P/N ID OD Thickness<br />

# of<br />

Slots<br />

Teflon ® CW1902783 .265 .625 .250 12<br />

CW1900783 .391 .625 .250 12<br />

CW1904783 .265 .625 .100 12<br />

Ceramic CW1902473 .265 .625 .250 12

Shoulder Washers<br />

Spacers & Flat Washers<br />

Material<br />

Ceramic<br />

Dimensions (inches)<br />

P/N L A B G F<br />

SW1402473 .050 .375 .090 .193 .250<br />

SW1425473 .050 .625 .125 .250 .375<br />

TFE Glass SW1439785 .109 .625 .094 .250 .313<br />

Teflon ® SW1419783 .109 .625 .188 .250 .375<br />

SW1400783 .109 .625 .109 .250 .313<br />

SW1402783 .063 .375 .063 .188 .250<br />

SW1403783 .125 .625 .438 .250 .406<br />

SW1406783 .234 .625 .109 .250 .375<br />

SW1407783 .109 .625 .109 .250 .375<br />

SW1413783 .063 .656 .500 .250 .406<br />

SW1418783 .125 .641 .500 .359 .453<br />

Nylon<br />

SW1420783 .188 .625 .109 .250 .375<br />

SW1421783 .125 .438 .063 .188 .297<br />

SW1423783 .055 .625 .500 .250 .531<br />

SW1424783 .063 .750 .250 .250 .500<br />

SW1425783 .050 .625 .109 .250 .375<br />

SW1426783 .050 .625 .313 .250 .375<br />

SW1427783 .313 .500 .063 .203 .313<br />

SW1443709 .125 .375 .031 .188 .250<br />

SW1427709 .313 .500 .063 .203 .313<br />

SW1444709 .047 .375 .094 .188 .250<br />

Teflon ® Dimensions (inches)<br />

Material P/N L A B<br />

ST1214783 .375 .625 .375<br />

ST1219783 .750 .750 .490<br />

ST1200783 .500 .375 .250<br />

ST1202783 .250 .375 .250<br />

ST1203783 .188 .375 .250<br />

ST1204783 .250 .625 .250<br />

ST1205783 .750 .500 .359<br />

ST1206783 .500 .500 .344<br />

ST1207783 .500 .625 .375<br />

ST1208783 .250 .625 .406<br />

ST1209783 .625 .625 .375<br />

ST1221783 .375 .500 .375<br />

ST1225783 .375 .625 .500<br />

ST1226783 1.00 .625 .265<br />

ST1231783 .125 .422 .363<br />

ST1232783 .375 .375 .250<br />

ST1253783 .062 .500 .250<br />

ST1254783 .062 .625 .250<br />

ST1255783 .125 .500 .125<br />

ST1256783 .188 .445 .250<br />

09709E1000-<br />

FW0000<br />

.047 .438 .203<br />

ST1240709 .062 .375 .203<br />

Nylon ST1239709 .062 .375 .250<br />

ST1230709 .125 .500 .313<br />

09709E2500-<br />

FW0000<br />

.094 .500 .250<br />

ST1220473 .250 .500 .375<br />

ST1240473 .062 .375 .188<br />

Ceramic ST1247473 .500 1.00 .560<br />

ST1248473 .125 .600 .394<br />

ST1249473 .125 .625 .250<br />

Fasteners<br />

We make a variety of fasteners in almost any material required, including:<br />

• Brass • HASTELLOY ® C-276<br />

• 304<br />

• Carpenter® 20Cb3<br />

• 316 • HASTELLOY ® B-2<br />

• Teflon®<br />

• Titanium<br />

• Nylon • INCONEL® alloy 600<br />

• Tantalum<br />

Teflon® is a registered trademark of DuPont. HASTELLOY® is a registered trademark of Haynes International, Inc. INCONEL® alloy 600 is a registered<br />

trademark of Special <strong>Metal</strong>s. Carpenter® 20Cb3 is a registered trademark of Carpenter Technologies.

Model SR3000<br />

Low Pressure Adjustable Coupon Insertion System<br />

I.L.*<br />

Insertion Rod<br />

3/4" or 1" Adjustable<br />

Mounting Plug<br />

Knob for Hand<br />

Insertion of System<br />

3"<br />

Coupon Adapter<br />

2" < Std. Length<br />

Safety Cable<br />

Model SR3000 coupon insertion system is an adjustable unit commonly used in the water treating<br />

industry. The system is designed to mount onto a 1” piping system, but can easily be adapted to<br />

fit your specific requirements. The system consists of an insertion rod with a coupon adapter. The<br />

standard assembly is available with 3/4” or 1” NPT threads on the mounting plug. A safety cable and<br />

safety nut are also provided to prevent blowout. Several coupon holders and lengths are available.<br />

Note: Since the adjustable mounting plug on the SR3000 is not a packing gland, some system leakage<br />

may occur if retracted or inserted into a pressurized system. Therefore, this model is suggested<br />

for use only in non-hazardous systems.<br />

*The insertion length (I.L.) shown here is based on a standard <strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring<br />

Systems part #CO118 coupon and may vary for other coupons depending on the coupon length and<br />

hole location.<br />

Specifications:<br />

Body - 316 Stainless Steel<br />

Temperature Rating - 100°F<br />

Pressure Rating - 125 PSI / 8.5 Bar (TFE Ferrule)<br />

- 1,500 PSI / 102 Bar (<strong>Metal</strong> Ferrule)<br />

Mounting - 1" Full Port Valve (Min.)<br />

Std. Length I.L. (max)<br />

18" 16.5"<br />

24" 22.5"<br />

30" 28.5"<br />

36" 34.5"<br />

42" 40.5"<br />

<strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems<br />

A Division of Alabama Specialty Products, Inc.<br />

152 <strong>Metal</strong> <strong>Samples</strong> Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515<br />

E-mail: msc@alspi.com Internet: www.metalsamples.com<br />

Houston Office: 6327 Teal Mist Lane, Fulshear, TX 77441 Phone: (832) 451-6825

SR3000 Ordering Information<br />

Model<br />

SR32<br />

SR33<br />

Low Pressure Adjustable Coupon Insertion System with 3/4" NPT<br />

Low Pressure Adjustable Coupon Insertion System with 1" NPT<br />

Insertion Rod & Mounting Material<br />

22<br />

44<br />

316<br />

C276<br />

Coupon Options<br />

010<br />

030<br />

Fits P/N CO100<br />

Fits P/N CO118<br />

Length<br />

18<br />

24<br />

30<br />

36<br />

42<br />

16.5 inches max. insertion length<br />

22.5 inches max. insertion length<br />

28.5 inches max. insertion length<br />

34.5 inches max. insertion length<br />

40.5 inches max. insertion length<br />

Coupon Adapter and Insulators<br />

1<br />

2<br />

4<br />

5<br />

SR32 22 030 18 4 Example of Probe Ordering #<br />

Coupon adapter same material as rod, Teflon ® insulators<br />

Teflon ® coupon adapter, Teflon ® insulators<br />

Coupon adapter same material as rod, nylon insulators (standard)<br />

Nylon coupon adapter, nylon insulators<br />

For alloys, sizes, or other special requirements not listed, contact our sales department.

Model RT4000<br />

Coupon Insertion System<br />

Retractable with Packing Gland<br />

I.L.*<br />

Knob for Hand<br />

Insertion of Probe<br />

3"<br />

1" NPT<br />

Coupon<br />

Coupon Adapter<br />

Safety Chain<br />

2" < Std. Length<br />

Adapter for Easytool<br />

Insertion of Probe<br />

Model RT4000 coupon insertion system is a retractable unit commonly used in field and plant<br />

applications. A specially designed packing gland is used to insert or retract a coupon from a pressurized<br />

system without a process shutdown. The insertion system is designed to mount onto a 1" piping<br />

system, but can easily be adapted to fit your specific requirements. The system consists of an insertion<br />

rod with a coupon adapter, and a packing gland. A safety chain and safety nut are also provided<br />

to prevent blowout. Standard packing material in the packing gland is Teflon ® , however, grafoil<br />

packing can be provided for high temperature applications. (Special consideration must be given to<br />

the insulator material selection for high temperature applications. Contact our sales department for<br />

assistance.) Several coupon holders and lengths are available. *The insertion length (I.L.) shown<br />

here is based on a standard <strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems part #CO118 coupon and<br />

may vary for other coupons depending on the coupon length and hole location.<br />

Specifications:<br />

Body - 316 Stainless Steel<br />

Temperature Rating - 500°F / 260°C - Teflon ®<br />

850°F / 454°C - Grafoil<br />

Pressure Rating - 1500 PSI / 102 Bar<br />

Mounting - 1" Full Port Valve (Min.)<br />

S td. Length I.L. (Max.)<br />

24"<br />

18.54"<br />

30"<br />

24.54"<br />

36"<br />

30.54"<br />

42"<br />

36.54"<br />

The Easy Tool is required for probe insertion or<br />

retraction in systems with pressure over 150 pounds.<br />

<strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems<br />

A Division of Alabama Specialty Products, Inc.<br />

152 <strong>Metal</strong> <strong>Samples</strong> Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515<br />

E-mail: msc@alspi.com Internet: www.metalsamples.com<br />

Houston Office: 6327 Teal Mist Lane, Fulshear, TX 77441 Phone: (832) 451-6825

Model<br />

RT45<br />

RT75<br />

RT00<br />

RT4000 Ordering Information<br />

®<br />

R etractable Coupon Insertion System 1" Female NPT, Packing Gland with Teflon<br />

Retractable Coupon Insertion System 1" Female NPT, Packing Gland with Grafoil<br />

Retractable Coupon Insertion System Replacement Insertion Rod<br />

Insertion Rod & Mounting Material<br />

20 316 (when ordering only Insertion Rod - RT00)<br />

22 316<br />

40 C276 (when ordering only Insertion Rod - RT00)<br />

44 C276<br />

Coupon Options<br />

010 Fits P/N CO100<br />

030 Fits P/N CO118<br />

040 Fits P/N ES200 (Cylindrical Coupons)<br />

050 Fits P/N CO111<br />

060 Fits P/N CO220<br />

Length<br />

24 18.54 inches max. insertion length<br />

30 24.54 inches max. insertion length<br />

36 30.54 inches max. insertion length<br />

42 36.54 inches max. insertion length<br />

Coupon Adapter and Insulators<br />

®<br />

1 C oupon adapter same material as rod, Teflon insulator s<br />

® ®<br />

2 T eflon c oupon adapter, Teflo n insulator s<br />

3 Coupon adapter same material as rod, ceramic insulators<br />

4 Coupon adapter same material as rod, nylon insulators<br />

5 Nylon coupon adapter, nylon insulators<br />

6 Coupon adapter same material as rod, no insulators<br />

RT45<br />

22<br />

030<br />

24<br />

1 Example of Probe Ordering #<br />

For alloys, sizes, or other special requirements not listed, contact our sales department.

Corrosion Coupons<br />

for High Pressure Access Systems<br />

Corrosion coupons are generally used in weight loss tests. Properly<br />

selected, such coupons will provide quantitative estimates of<br />

corrosion rates as well as physical evidence of the type of corrosion<br />

occurring in the process environment. In order to provide<br />

reproducible data, selected coupons must have a uniform shape,<br />

size, surface area, and surface finish. Coupons should be fabricated<br />

of an alloy that is similar in composition to the process equipment of<br />

interest.<br />

NACE has published a Recommended Practice RP-0775 entitled Preparation and Installation of Corrosion<br />

Coupons and Interpretation of Test Data in Oil Production Practice.<br />

Strip Coupons<br />

Strip coupons are available in two standard sizes: 3" x 7/8" x 1/8" (76 mm x 22 mm x 3 mm) and 6" x 7/8"<br />

x 1/8" (152 mm x 22 mm x 3 mm). Both sizes have two mounting holes for attachment to the Strip Coupon<br />

Holder. Strip coupons are supplied complete with nylon insulation for mounting purposes. Strip coupons are<br />

typically mounted in pairs and need to be oriented such that they are parallel to the direction of flow.<br />

3" Strip<br />

(PN CO111)<br />

6" Strip<br />

(PN CO169)<br />

Flush Disc Coupons<br />

These circular coupons are most commonly used with holders that mount the coupon flush with the interior<br />

of the pipe or vessel. They have a chamfered hole which permits recessed mounting with a stainless steel<br />

flathead screw. Flush disc coupons are most frequently used where pigging would otherwise require the<br />

removal of intrusive-type coupon assemblies prior to the pigging operation; or alternatively where waterdrop<br />

out in the bottom of horizontal pipe runs gives rise to corrosion problems. The disc coupon diameter<br />

is 1¼" (32 mm) with a thickness of 1/8" (3 mm). The insulation and mounting screw is provided with the<br />

coupon holder.<br />

Flush Disc<br />

(PN CO142)

Ladder Strip Coupons<br />

These coupons are rectangular with the following dimensions: 2" x 7/8" x 1/8" (51 mm x 22 mm x 3 mm).<br />

They are designed to be mounted in pairs with three pairs of ladder strip coupons attached to a single ladder<br />

coupon holder. Ladder strip coupons are supplied with nylon insulation for mounting.<br />

2" Ladder<br />

(PN CO197)<br />

Scale Coupons<br />

Scale coupons are rectangular with a series of holes of varying sizes, and are used to determine scaling<br />

tendency. The strength of this tendency can be determined by the largest size hole that has accumulated<br />

scale. Scale coupons are typically used with strip coupon holders.<br />

3" & 6" Scale<br />

(PN CO185/196)<br />

• C1018 coupons are stamped with a sequence number. All alloy coupons are stamped with the<br />

alloy and the sequence number.<br />

• Coupons are pre-weighed and individually packaged in a vapor corrosion inhibitor (VCI) bag.<br />

• Coupons are supplied with a mill test report and a weight log chart.<br />

• Coupons are cleaned of all contaminants and have a 120 grit-blasted finish.<br />

• Nylon insulators are mounted into coupons.<br />

Coupon Holder Accessories:<br />

Part No.<br />

Description<br />

Strip Coupon Holder KR5119158 Mounting Kit - Coupon<br />

Disc Coupon Holder KR5120 Mounting Kit - Coupon<br />

Ladder Strip Coupon Holder KR5119158 Mounting Kit - Coupon<br />

<strong>Metal</strong> <strong>Samples</strong> Corrosion Monitoring Systems<br />

A Division of Alabama Specialty Products, Inc.<br />

152 <strong>Metal</strong> <strong>Samples</strong> Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515<br />

E-mail: msc@alspi.com Internet: www.metalsamples.com<br />

Houston Office: 6327 Teal Mist Lane, Fulshear, TX 77441 Phone: (832) 451-6825

HC Series Coupon Holders<br />

for High Pressure (HP TM and MH TM ) Access Systems<br />

Flush Disc 3" Strip 6" Strip Ladder<br />

Figure 1. Various coupon holder styles on HP access fittings.<br />

HC Series Coupon Holders are designed to be specifically compatible with either the HP or MH<br />

High Pressure Access Systems. The HP coupon holder can not be used with the MH system and vice<br />

versa. The HP coupon holder is attached to the solid plug assembly by means of a left-handed thread<br />

connection to ensure that it does not become loose during the retrieval procedure. The MH coupon<br />

holder is attached by means of a set screw arrangement and incorporates an orientation keyway feature<br />

to automatically align installed strip coupons parallel to the fluid flow.<br />

Coupon holders are manufactured from 316L stainless steel to meet NACE MR-0175 requirements<br />

for sour service. Mounting hardware is also manufactured from stainless steel and is supplied with<br />

coupon holders. Insulators are fabricated from Nylon and are supplied with the coupons. Coupons<br />

are ordered separately. Calculated lengths are rounded down to the nearest 1/8".<br />

Strip Coupon Holders<br />

Strip coupon holders are designed to suspend a pair of 3" or 6" coupons in a vessel or pipe.<br />

Calculating Strip Coupon Holder Length<br />

After selecting the access fitting body style to be used,<br />

determine the pipe or pressure vessel size and select the<br />

coupon length and line position where the coupon will<br />

be located. Coupon holders can be sized to monitor the<br />

top, middle, or bottom of the line. Use the following<br />

formulas to calculate the required holder length.<br />

With a non-flanged access fitting:<br />

Top-of-the-line Monitoring: L = (H + PW) - 2.5"<br />

Ordering Length<br />

Figure 2. Strip coupon holder

One half of the coupon extends into the pipe and the process environment. The other half is positioned<br />

in the access fitting body cavity and may be used to monitor the formation of gas pockets.<br />

Middle-of-the-line Monitoring: L = (H + ½OD) - (2.5" + ½CL)<br />

The coupon is centered so that ½ of the coupon is positioned on either side of the pipe’s centerline.<br />

Bottom-of-the-line Monitoring: L = (H + OD) - (2.75" + PW + CL)<br />

The coupon is positioned approximately ¼" off the bottom of the line.<br />

With a flanged access fitting:<br />

Top-of-the-line Monitoring: L = (H + FG + MH + PW) - (2.5" + ½CL)<br />

Middle-of-the-line Monitoring: L = (H + FG + MH + ½OD) - (2.5" + ½CL)<br />

Bottom-of-the-line Monitoring: L = (H + FG + MH + OD) - (2.75" + PW + CL)<br />

Where:<br />

L = Coupon holder length<br />

H = Height of the access fitting body without a thread protector<br />

(MH = 5.5"/14 cm, HP = 5.25"/13.3 cm)<br />

PW = Pipe wall thickness<br />

OD = Outside diameter of the pipe<br />

CL = Effective length of the coupon (the portion of the coupon that is actually exposed to the process environment)<br />

For a 3" coupon, CL = 1.625" (4.13 cm)<br />

For a 6" coupon, CL = 4.750" (12.07 cm)<br />

FG = Gap between mating flange faces<br />

MH = Mating flange height from face to top of pipe<br />

Disc Coupon Holders<br />

Disc coupon holders are used with flush disc type coupons for measurement in either flush or nonintrusive<br />

configurations. They are available as fixed length or adjustable assemblies. These coupon<br />

holders offer the following advantages over strip coupon holders:<br />

1) They can be mounted flush with the pipe wall so that process effects occurring at the pipe<br />

wall are closely simulated.<br />

2) Holders properly sized to the flush position prevent coupon interference with pigging operations.<br />

3) Orientation of coupons to process flow is not required.<br />

Fixed Length Flush Disc Holder<br />

The fixed length flush disc coupon holder may be sized so that<br />

the coupon is positioned flush with the pipe wall, or is extended<br />

into the line at the top, center, or bottom position.<br />

The customer must specify holder length when ordering. For<br />

MH systems, minimum fixed length disc holder length is 2.875<br />

inches (7.3 cm). For HP systems, minimum fixed length disc<br />

holder length is 2.0 inches (5.08 cm). Fixed length holders are<br />

available in increment lengths of 0.125 inches (3.2 mm).<br />

Ordering Length<br />

Figure 3. Fixed Length<br />

Flush Disc Coupon Holder<br />

Holders - 2

Adjustable Length Flush Disc Holder<br />

Disc holder lengths start at 2.75" and are available in 1/8" increments.<br />

The holder’s adjustable rod allows for a total travel<br />

length of 1.5". Example: A 3.25" holder would be adjustable<br />

from 3.25 to 4.75 inches.<br />

Figure 4. Adjustable Length<br />

Flush Disc Coupon Holder<br />

Calculating Disc Coupon Holder Length<br />

Select the access fitting body style and determine the pipe or vessel size and line position where the<br />

coupon will be located. Then use the appropriate formula below to calculate the required fixed length<br />

disc coupon holder.<br />

With a non-flanged access fitting:<br />

Flush Monitoring: L = (H + PW) - (2.5")<br />

Middle-of-the-Line Monitoring: L = (H + ½OD) - (2.375")<br />

Bottom-of-the-Line Monitoring: L = (H + OD) - (PW + 2.75")<br />