Strip weld overlay - Oerlikon

Strip weld overlay - Oerlikon

Strip weld overlay - Oerlikon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

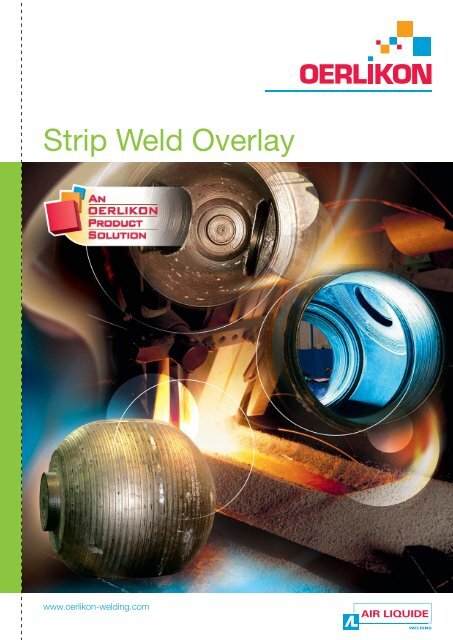

<strong>Strip</strong> Weld Overlaywww.oerlikon-<strong>weld</strong>ing.com

OERLIKON Solutions<strong>Strip</strong> Weld OverlayIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2OERLIKON and <strong>Strip</strong> Weld Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3The Process of <strong>Strip</strong> Weld Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4General Considerations: Welding Parameters . . . . . . . . . . .5General Requirements of the Overlay . . . . . . . . . . . . . . . . . . . . . . .6Flux■ Fluxes for the Submerged Arc Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7■ Fluxes for the Electroslag Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8SUPRASTRIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9■ OERLIKON stainless steel SUPRASTRIP■ OERLIKON nickel base SUPRASTRIPRecommended combinations and parametersTypical OERLIKON solutions for:■ Alloy 308L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10■ Alloy 316L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 to 12■ Alloy 317L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13■ Alloy 347 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 to 15■ Alloy 385L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16■ Alloy 410S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17■ Alloy 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18■ Alloy 625 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19■ Alloy 825 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Equipment for Weld Overlay Applications . . . . . . . . . . . . . . .211

IntroductionAir Liquide SA, with its headquarters in Paris, France,is one of Europe’s larger multinational companies.It had a consolidated turnover of €14.5 billion in 2011with 46.200 employees all over the world.2009-3054Air Liquide Welding is represented throughout the world byindividual ALW companies with a brand portfolio optimisedlocally to the needs of all types of customers. OERLIKON brandis an important part of this portfolio and has a long anddistinguished history of innovation in <strong>weld</strong>ing products.These ALW companies are involved in many different areas ofOERLIKON product design, development and application.The research and development centre, AL CTAS, is located inParis and is the largest privately owned centre for <strong>weld</strong>ing R&D.This facilitates the rapid transfer and implementation ofimportant innovations and advances in <strong>weld</strong>ing technologythroughout the whole of the OERLIKON global network. Theutilisation of the strengths and experience of this networkenables OERLIKON to maintain its position and internationalreputation for innovative leadership at the forefront of advanced<strong>weld</strong>ing technology in both <strong>weld</strong>ing consumables andincreasingly equipment and processes.With this background, OERLIKON has generated a provenhistory of supplying <strong>weld</strong>ing consumables on an ongoing basisfor the most demanding and critical applications, particularly inthe energy sector to industries such as offshore oil and gas andnuclear power generation. OERLIKON has continued to workclosely with owners, construction contractors and fabricatorsto supply customised solutions through performance andinnovation by developing and supplying <strong>weld</strong>ing products andprocesses capable of meeting the stringent mechanical propertyspecifications and increasingly the demands for enhanced<strong>weld</strong>ing productivity.The results of this process of ongoing innovation and productdevelopment are demonstrated by the range of automatedinstallations, <strong>weld</strong>ing consumables and equipment specificallytailored for the high productivity requirements of the fabricationindustry.2

OERLIKON and <strong>Strip</strong> Weld OverlayA commitment to technical excellence supportedby a dedication to quality is regarded as fundamentalto OERLIKON’s success with fabricators world wide.3534-53QualityOERLIKON has a total commitment to quality. The productranges are manufactured in group production facilities, allof which are ISO certified. Detailed certification for <strong>weld</strong>ingconsumables is supplied as a matter of routine and customers’special quality requirements for increased frequency of batchtesting or specialised certification are also readily accommodated.This ensures the reliability and reproducibility fabricators needin industries such as petrochemicals and power generation.InformationAll OERLIKON products are backed by a full technicalinformation package, which is available in printed or electronicformat, on the OERLIKON web sites. Product information iswritten to enable the professional <strong>weld</strong>ing engineer to select thecorrect OERLIKON product for the application. In order toelaborate the technology of the product range in more detail,technical articles are available in the journal of OERLIKON’s<strong>weld</strong>ing and cutting expertise, “Competence”.Technical ServiceOERLIKON’s involvement with its products does not stop atmanufacture. OERLIKON provides a close and detailedparticipation with the application of products, right from the initialselection to <strong>weld</strong>ing characteristics on site. A team of highlyqualified engineers is ready to respond, with the objective ofproviding technologically relevant and practical solutions.This is of particular relevance for activities such as refinerymaintenance during a shut down when solutions must beidentified under time pressure. A large information base is at theservice of every customer to ensure the most cost effectiveselection of process and <strong>weld</strong>ing procedure to meet the needsof any application.FlexibilityThe OERLIKON product range is continuously developing inresponse to changing technological requirements. As new steeltypes are developed and used, as new more demandingapplications are developed, so OERLIKON reacts to provide theright products, regularly meeting with engineering departmentsand major manufacturers at the design stage to ensure optimum<strong>weld</strong>ing solutions.Track RecordOERLIKON is a technological innovator and major supplier of<strong>weld</strong>ing products to large industries. A track record of highlysuccessful products combining quality and technology withtechnical service has been firmly established.3534-575000-03663

The Process of <strong>Strip</strong> Weld OverlayAs many industries require equipment to work at elevated temperatures, in corrosive media andunder high pressure, the use of highly alloyed materials for the fabrication of completecomponents becomes financially unrealistic as their size increases. One solution for stainlesssteels and other highly alloyed materials, such as nickel base alloys, is to deposit a <strong>weld</strong> <strong>overlay</strong>on the surface of the equipment to resist corrosion attack.Dual-material clad plate utilises a thin layer of the costly higheralloyed material which is in contact with the corrosive media,while the lower cost substrate is used to give the desiredstructural integrity. The application of the high alloyed layercan be accomplished by several methods including, dual rolling,explosive bonding and <strong>weld</strong> <strong>overlay</strong>. However the most flexibleof these methods is <strong>weld</strong> <strong>overlay</strong>.Weld <strong>overlay</strong> gives the designer and fabricator flexibility to choosea wide variety of load bearing materials as substrates, as well asa wide variety of wire/strip chemistries to deposit the required <strong>overlay</strong>.In general, the use of <strong>weld</strong> <strong>overlay</strong> to surface finish shaped componentseliminates the eventual problems arising with cold or hot forming.All the <strong>weld</strong>ing processes can be utilised, however due to constraintsin the physical requirements, some are better suited than others.<strong>Strip</strong> Weld Overlay ProcessThe initial use of a strip instead of a wire withthe submerged arc process, was patentedin the US around 1922. Due to thedevelopment of the nuclear industry, thisprocess became industrial, and is nowconsidered as a mature process.Several modifications of submerged-arc<strong>weld</strong>ing with strip have been developedmainly with a view to further increasing thedeposition rate and to decrease the dilution.There are two strip processes: SubmergedArc <strong>Strip</strong> (SAW) and Electroslag <strong>Strip</strong> (ESW).Among all the <strong>weld</strong>ing processes,submerged arc and electroslag strip <strong>weld</strong><strong>overlay</strong> offer the highest deposition rate, thebest bead characteristics and trouble freeoperation using standard SAW <strong>weld</strong>ingequipment.The Submerged Arc <strong>Strip</strong> process(SAW Fig. 1) uses an arc that runs back andforth at high speed along the strip, meltingthe strip, the base metal and the flux toobtain the <strong>overlay</strong> onto the base material.Because this is an arc process, there ispenetration into the base material resultingin dilution levels of ~20%. For a strip of60 mm, deposition rates are in the regionof 12-14 kg/hr.The Electroslag <strong>Strip</strong> process (ESW) Fig. 2ignites like the submerged arc process.When a sufficient amount of flux is melted,because the molten flux has a lowerelectrical resistance than the electric arc, thecurrent flows through the shallow layer ofconductive slag, and the arc is extinguished.The process produces sufficient heat tokeep the process stable and to melt thestrip into the liquid slag; which istransferred into molten metal depositedonto the base material.The ESW process has significantadvantages over its SAW counterpart:1. As there is no arc present, there islimited dilution into the base material,typically 10% (compared with 20% forSAW using 60 x 0.5 mm strip). Thisleads to the ability to deposit singlelayer full chemistry with over alloyedstrip, even when a low carbon gradeis required.2. Due to the smooth operation of thisprocess, higher current levels can beused resulting in deposition rates upto 40 kg/hr for 60 mm strip.3. Electroslag refining occurs when themolten metal passes through the slagbath, resulting in cleaner <strong>weld</strong> metalwith a lower risk of hot cracks, evenfor fully austenitic deposits.4. The electroslag process cannot beused with carbon steel strip, becauseof the higher electricity conductibilitythan stainless or nickel strip.Fig. 1: Submerged arcprocess <strong>weld</strong> <strong>overlay</strong><strong>Strip</strong> feed systemFig. 2: Electroslagprocess <strong>weld</strong> <strong>overlay</strong><strong>Strip</strong> feed systemFlux supplyFlux burdenStick out(30-40 mm)BasemetalLiquidslag<strong>Strip</strong>LiquidmetalElectricalpick-upFluxsupplyPenetration(0.3 - 0.5 mm)Weld<strong>overlay</strong>Solidified slagThicknessof <strong>overlay</strong>Flux supplyFlux burdenStick out(30-40 mm)BasemetalLiquidslag<strong>Strip</strong>Electricalpick-upLiquidmetalPenetration(0.3 - 0.5 mm)Weld<strong>overlay</strong>Solidified slagThicknessof <strong>overlay</strong>Travel direction of the headTravel direction of the head4

General Considerations: Welding Parameters2005-502Current and <strong>weld</strong>ing speedIn <strong>weld</strong> <strong>overlay</strong>, the requirement is to deposit an alloy which isquite different from the base metal. If the 2 main parameterswhich govern the dilution are the current and the <strong>weld</strong>ing speed,other parameters also need to be taken in consideration:voltage, stick-out, size of strip, and in the case of circumferentialsurfacing, the strip position related to the diameter of the workneeds to be controlled.For a stainless steel strip of 60 x 0.5 mm, all other parametersremaining constant, when the current increases, the thicknessdeposited increases and the dilution decreases.Fig. 3, illustrates the influence of the current and the <strong>weld</strong>ingspeed on the dilution and the thickness deposited.Fig. 3: Dilution and thickness related tocurrent and <strong>weld</strong>ing speed% Dilution242220181614121081,5 m/min(1250 A)(~24 kg/h)2,5 m/min(1800 A)(~36 kg/h)Thickness(mm)654VoltageGenerally the voltage should be set between 24 V and 25 V,as an excessive voltage generates spatter and too low a voltageinduces current instability.Stick outStandard stick out is around 30-35 mm, a short stick outgenerates spatter, an increase of stick out from 30 mm to 50 mmwill reduce the dilution level slightly (e.g. from 10% to 8%) but thesmoothness of the surface deteriorates.Size of stripWith the same current density, typically used in ESW:~ 40 A/mm², as the width of the strip increases, the dilution leveldecreases: ~12% for a strip of 30 mm, ~10% for a stripof 60 mm and ~9% for a strip of 90 mm.Number of layersDuring the <strong>weld</strong>ing of the first layer, the deposit is generally quitedifferent from the base material, but for the subsequent layers,the deposit is generally similar to the first layer. For the ESWprocess, when a first layer is <strong>weld</strong>ed with a strip type 309L, on acarbon steel plate, with typical parameters, the dilution is about10%, the second layer, <strong>weld</strong>ed with same parameters, will havea dilution around 25%.648 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46Magnetic steering deviceMagnetic steering is used to reduce the risk of lack of fusionat the overlap, and to increase the flatness of the surface of thedeposit.<strong>Strip</strong> positioning1,5 m/min 1,5 m/minWhen working on a curved surface, the molten pool is relativelylarge, and the liquid slag and the liquid metal have the tendencyto flow to the lowest point of the curved surface. Thus, theposition of the strip will have a big influence on the dilution leveland on the profile of the bead. This effect takes place when thediameter becomes smaller than 3 metres, the smaller thediameter, the bigger the influence.For more information about these parameters,please contact OERLIKON Service.Welding speedcm/min35

General Requirements of the Overlay2570-255000-0365Specifications generally require a ferrite level on the surface and chemical composition at a specified distancefrom the surface. The deposit will pass corrosion resistance and guided side-bend testing after post <strong>weld</strong> heattreatment. If the equipment is required to conform to ASME IX code, reference should be made to QW-214Chemical analysisGenerally, the specified chemical analysis is required to conformto the composition for the undiluted <strong>weld</strong> metal of the equivalentAWS grade MMA electrode.For applications in the petrochemical industry, the requiredanalysis needs to be controlled at -3 or 3.2 mm bellow thesurface of the deposit.For applications in the nuclear industry, the requirement is generallyfor the undiluted <strong>weld</strong> metal from the “strip -flux” combination.Ferrite levelFerrite level is generally indicated in FN (Ferrite Number) and iscalculated using the WRC 92 diagram or measured on thesurface of the deposit, in the as <strong>weld</strong>ed condition, with acalibrated instrument.For petrochemical industry applications, a minimum ferritenumber is specified, FN 3 to 5, to avoid hot cracking, and amaximum ferrite number is specified, FN 8 to 10, to avoid acontinuous band of delta ferrite, where sigma phase can beformed during PWHT.In case of specific corrosive environments such as ureaspecifications, ferrite should be minimised, FN

AST and ELT fluxesSimilar to other <strong>weld</strong>ing processes, the most sophisticated components are the coating of an MMAelectrode and the flux for the submerged arc process, which determine the quality of the <strong>weld</strong> deposit.Welding fluxes are characterized by their basicity, granulometry and composition. The most importantcharacteristics of the liquid slag which is formed during the process are: viscosity, solidificationtemperature range, surface tension and interaction with the chemistry of the deposit.For many years, the extensive R&D commitment of OERLIKONhas continued to contribute to the knowledge of raw materialsand experience in flux formulation used in both the submergedarc and electroslag processes.Generally, submerged arc fluxes contain small quantitiesof alloying elements, mainly Cr, to compensate burn-out dueto the electrical arc. In the electroslag process, there is no arc,the burn out of Cr is hence reduced. No alloying elementsare required and these fluxes are neutral. In some cases,when specific strip compositions are not available,compensated fluxes are required to reach specific analyses.The main characteristics for electro slag fluxes are a largequantity of fluoride and very low silicon oxide content.Due to the large quantity of fluoride, these fluxes are ableto form a shallow layer of electrically conductive molten flux.Due to the very low silicon oxide content, the deposited metalcontains an extremely low oxygen concentration anda high degree of purity in terms of levels and size of non metallicinclusions. This is important for obtaining a good resistanceto pitting corrosion.OERLIKON DRYBAG and METAL DRUMS packaging arecompletely moisture proof requiring no controlled climaticconditions and as such can be used for <strong>weld</strong>ing without anyreconditioning or re-baking. Before use, the packaging integrityshould be checked. If the bags or drums show signs of puncturethen the contents must be re-dried or discarded.2007-4740109-33_retFluxes for the Submerged Arc ProcessDesignation Classification FeaturesAST 100 BAST 300AST 600ISO 14174 -S A CS 3ISO 14174 -S A CS 2BISO 14174 -S A AB 2BAgglomerated and alloyed flux (nickel and molybdenum) for strip <strong>weld</strong> <strong>overlay</strong> applications using the submergedarc process. It has been designed to produce a <strong>weld</strong> metal deposit with a martensitic structure in conjunction withSUPRASTRIP 430 stainless strip. Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.Agglomerated and chromium compensated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the submerged arc process.Highly basic agglomerated flux specially designed for use with stainless steel <strong>weld</strong>ing strips.Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.Neutral agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the submerged arc process.Highly basic agglomerated flux specially designed for use with nickel base <strong>weld</strong>ing strips.Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.7

AST and ELT fluxes0109-200109-19Fluxes for the Electroslag ProcessDesignation Classification FeaturesELT 300ELT 300 SELT 308-1ELT 316-1ELT 347-1ELT 317-1ELT 600ELT 600 SELT 625-1ELT 825-1ISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BISO 14174 -ES A FB 2BNeutral agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process.Highly basic agglomerated flux specially designed for <strong>weld</strong>ing with stainless steel strips.Due to the very high hot cracking resistance, this flux can be used to deposit fully austenitic <strong>weld</strong> metals.Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.Neutral agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process;this revised formulation is used from low to high speeds, from 10 to 50 cm/min.Highly basic agglomerated flux specially designed for use with stainless steel <strong>weld</strong>ing strips.Due to the very high hot cracking resistance, this flux can be used to deposit fully austenitic <strong>weld</strong> metals.Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.Compensated agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process,Highly basic agglomerated flux specially designed for single layer deposit, with SUPRASTRIP 19 9 L to attainASME 5.4 E 308L.Compensated agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process,Highly basic agglomerated flux specially designed for use with SUPRASTRIP 19 12 3 L to depositan ASME 5.4 E 316L classification in one layer. This flux is used when >2.5% Mo is required in the deposit.Compensated agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process.Highly basic agglomerated flux specially designed for use with SUPRASTRIP 19 9 LNb to depositan ASME 5.4 E 347 classification in one layer.Compensated agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process.Highly basic agglomerated flux specially designed for use with SUPRASTRIP 19 13 4 L stainlesssteel strip to deposit an ASME 5.4 E 317L classification in one layer.Neutral agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process.Highly basic agglomerated flux specially designed for use with nickel base <strong>weld</strong>ing strips:Due to the very high resistance to hot cracking, this flux can be used to deposit fully austenitic metals.Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.Neutral agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process at high speed.Highly basic agglomerated flux specially designed for use with nickel base <strong>weld</strong>ing strips.Due to the very high resistance to hot cracking, this flux can be used to deposit fully austenitic <strong>weld</strong> metals.Excellent slag removal and good wettability, producing a smooth <strong>weld</strong> surface.Compensated agglomerated flux for strip <strong>weld</strong> <strong>overlay</strong> applications using the electroslag process.Highly basic agglomerated flux specially designed for use with SUPRASTRIP 625 to depositan ASME 5.11: E NiCrFe3 classification in one layer, with Fe

SUPRASTRIPOERLIKON SUPRASTRIP are solid strips usedfor <strong>weld</strong> <strong>overlay</strong>. In the past, some sintered stripsand some flux cored strips have been used.1369-02The most common thickness for <strong>weld</strong>ing strip is 0.5 mm, except in some Asian countries wherethe thickness is 0.4 mm. The standard widths are 30, 60, 90 and 120 mm. On request, OERLIKONcan provide SUPRASTRIP from

Recommended combinations and parametersTypical OERLIKON solutions for Alloy 308L308LWelding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 19 9 L 60 x 0.5 mm- Flux: AST 300Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties(typical indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 24 13L 0.014 2.0 0.4 23.7 13.1 0.1 0.045 -SUPRASTRIP 19 9L 0.014 1.9 0.3 20.1 10.5 0.1 0.045 -Surface - 3.0 mm 0.030 1.7 0.9 19.0 10.2 0.1 0.045 6Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 19 9 L 60 x 0.5 mm• Flux: ELT 308-1Base material• Type P1 according to ASME IX, thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CWelding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties(typical indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hChemical analysis (typical values):Analysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - -SUPRASTRIP 19 9L 0.014 1.9 0.3 20.1 10.5 0.1 0.045 -Surface - 3.0 mm 0.015 1.7 0.6 19.5 10.2 0.08 0.045 5Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 22 11 L 60 x 0.5 mm• Flux: ELT 300 or ELT 300SBase material• Type P1 according to ASME IX, thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CWelding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties(indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hChemical analysis (typical values):Analysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - -SUPRASTRIP 22 11 L 0.014 1.9 0.3 21.1 11.1 0.1 0.045 -Surface - 3.0 mm 0.030 1.7 0.6 19.1 10.1 0.08 0.045 5Welding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: ELT 300 S• Second First layer:- Electrode: SUPRASTRIP 19 9 L 60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 24 13L 0.014 2.0 0.4 23.7 13.1 0.1 0.045 -SUPRASTRIP 19 9L 0.014 1.9 0.3 20.1 10.5 0.1 0.045 -Surface - 3.0 mm 0.030 1.7 0.6 19.0 10.2 0.1 0.045 610

Typical OERLIKON solutions for Alloy 316L316LWelding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 21 13 3 L 60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 19 12 3 L 60 x 0.5 mm- Flux: AST 300Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 21 13 3 L 0.015 1.9 0.4 20.5 13.7 2.8 0.045 -SUPRASTRIP 19 12 3 L 0.015 1.9 0.4 18.5 12.7 2.7 0.045 -Surface - 3.0 mm 0.025 1.6 0.9 18.0 12.3 2.5 0.045 5Welding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 19 12 3 L 60 x 0.5 mm- Flux: AST 300Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 24 13 L 0.015 1.9 0.4 23.7 13.1 0 0.045 -SUPRASTRIP 19 12 3 L 0.015 1.9 0.4 18.5 12.7 2.7 0.045 -Surface - 3.0 mm 0.025 1.6 0.9 18.5 12.1 2.2 0.045 6Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 19 12 3 L 60 x 0.5 mm• Flux: ELT 316-1Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 19 12 3 L 0.015 1.9 0.4 18.5 12.7 2.7 0.045 -Surface - 3.0 mm 0.025 1.6 0.6 18.1 12.2 2.6 0.045 6Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 21 13 3 L 60 x 0.5 mm• Flux: ELT 300 or ELT 300SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 21 13 3 L 0.015 1.9 0.4 20.5 13.7 2.8 0.045 -Surface - 3.0 mm 0.025 1.6 0.6 18.5 12.5 2.5 0.045 511

Recommended combinations and parametersTypical OERLIKON solutions for Alloy 316L316LWelding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 21 13 3 L 60 x 0.5 mm- Flux: ELT 300 S• Second layer:- Electrode: SUPRASTRIP 19 12 3 L 60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 21 13 3 L 0.015 1.9 0.4 20.5 13.7 2.8 0.045 -SUPRASTRIP 19 12 3 L 0.015 1.9 0.4 18.5 12.7 2.7 0.045 -Surface - 3.0 mm 0.025 1.6 0.6 18.0 12.3 2.5 0.045 5Welding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: ELT 300 S• Second layer:- Electrode: SUPRASTRIP 19 12 3 L 60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 24 13 L 0.015 1.9 0.4 23.7 13.1 0 0.045 -SUPRASTRIP 19 12 3 L 0.015 1.9 0.4 18.5 12.7 2.7 0.045 -Surface - 3.0 mm 0.025 1.6 0.6 19.0 12.6 2.2 0.045 612

Typical OERLIKON solutions for Alloy 317L317LWelding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 21 13 3 L 60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 19 13 4 L 60 x 0.5 mm- Flux: AST 300Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 21 13 3 L 0.015 1.9 0.4 20.5 13.7 2.8 0.045 -SUPRASTRIP 19 13 4 L 0.015 1.9 0.4 18.8 13.5 3.6 0.045 -Surface - 3.0 mm 0.025 1.6 0.9 18.3 12.9 3.2 0.045 5Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 19 13 4 L 60 x 0.5 mm• Flux: ELT 317-1Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 19 13 4 L 0.015 1.9 0.4 18.8 13.5 2.8 0.045 -Surface - 3.0 mm 0.025 1.5 0.5 18.4 13.2 3.1 0.045 6Welding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 21 13 3 L 60 x 0.5 mm- Flux: ELT 300 S• Second layer:- Electrode: SUPRASTRIP 19 13 4 L 60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 21 13 3 L 0.015 1.9 0.4 20.5 13.7 2.8 0.045 -SUPRASTRIP 19 13 4 L 0.015 1.9 0.4 18.8 13.5 3.6 0.045 -Surface - 3.0 mm 0.025 1.4 0.6 18.3 13.3 3.2 0.045 613

Recommended combinations and parametersTypical OERLIKON solutions for Alloy 347347Welding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L Nb 60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 19 9 L Nb 60 x 0.5 mm- Flux: AST 300Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - - -SUPRASTRIP 24 13 L Nb 0.020 2.1 0.4 23.9 12.9 0.1 0.7 0.040 -SUPRASTRIP 19 9 L Nb 0.015 1.7 0.4 19.8 10.6 0.1 0.5 0.040 -Surface - 3.0 mm 0.025 1.7 0.6 19.5 10.5 0.1 0.45 0.045 6Welding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 19 9 L Nb 60 x 0.5 mm- Flux: AST 300Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - - -SUPRASTRIP 24 13 L 0.020 2.1 0.4 23.9 12.9 0.1 - 0.040 -SUPRASTRIP 19 9 L Nb 0.015 1.7 0.4 19.8 10.6 0.1 0.5 0.040 -Surface - 3.0 mm 0.025 1.7 0.6 19.5 10.5 0.1 0.33 0.045 7Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 19 9 L Nb 60 x 0.5 mm• Flux: ELT 347-1Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - - -SUPRASTRIP 19 9 L Nb 0.015 1.7 0.4 19.8 10.6 0.1 0.5 0.040 -Surface - 3.0 mm 0.025 1.7 0.6 19.6 10.4 0.1 0.4 0.045 7Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 21 11 L Nb 60 x 0.5 mm• Flux: ELT 300 or ELT 300SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 24 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - - -SUPRASTRIP 21 11 LNb 0.018 1.8 0.4 21.4 11.3 0.1 0.6 0.045 -Surface - 3.0 mm 0.025 1.7 0.6 19.3 10.2 0.1 0.4 0.045 714

Typical OERLIKON solutions for Alloy 347347Welding Process ESW single layer High speedWelding consumables• Electrode: SUPRASTRIP 24 13 L Nb 60 x 0.5 mm• Flux: ELT 300 SBase material• Type 2.25Cr 1Mo, thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1800 A - Voltage: 24 V• Welding speed: 45 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.1 mm• Deposition rate: 35 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.15 1.2 0.4 2.25 - 1.0 - - -SUPRASTRIP 24 13 L Nb 0.020 2.1 0.4 23.9 12.9 0.1 0.7 0.040 -Surface - 3.0 mm 0.045 1.3 0.6 19.5 10.4 0.22 0.54 0.045 6Welding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: ELT 300 S• Second layer:- Electrode: SUPRASTRIP 19 9 L Nb 60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.18 1.2 0.4 0.21 - 0.01SUPRASTRIP 24 13 L 0.020 2.1 0.4 23.9 12.9 0.1 0.040SUPRASTRIP 19 9 L Nb 0.015 1.7 0.4 19.8 10.6 0.1 0.5 0.040Surface - 3.0 mm 0.025 1.7 0.6 19.6 10.4 0.1 0.30 0.045 7Welding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L Nb 60 x 0.5 mm- Flux: ELT 300 S• Second layer:- Electrode: SUPRASTRIP 19 9 L Nb 60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo Nb N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - - -SUPRASTRIP 24 13 L Nb 0.020 2.1 0.4 23.9 12.9 0.1 0.7 0.040 -SUPRASTRIP 19 9 L Nb 0.015 1.7 0.4 19.8 10.6 0.1 0.5 0.040 -Surface - 3.0 mm 0.025 1.7 0.6 19.6 10.4 0.1 0.45 0.045 715

Recommended combinations and parametersTypical OERLIKON solutions for Alloy 385LWelding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 20 25 5 LCu60 x 0.5 mm- Flux: AST 300• Second layer:- Electrode: SUPRASTRIP 20 25 5 LCu60 x 0.5 mm- Flux: AST 300Welding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 20 25 5 LCu60 x 0.5 mm- Flux: ELT 300 S• Second layer:- Electrode: SUPRASTRIP 20 25 5 LCu60 x 0.5 mm- Flux: ELT 300 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Typical OERLIKON solutions for Duplex stainless steel385LDuplexWelding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo Cu NBase material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 20 25 5 LCu 0.015 1.6 0.3 20.5 24.8 4.3 1.5 0.045Surface - 3.0 mm 0.015 1.2 0.7 19.1 24.0 4.1 1.3 0.045Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo N FNBase material 0.18 1.2 0.4 0.21 - 0.01 - -SUPRASTRIP 20 25 5 LCu 0.015 1.6 0.3 20.5 24.8 4.3 - -Surface - 3.0 mm 0.015 1.7 0.6 19.5 10.2 0.08 0.045 6Welding Process SAW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: AST 300• Second and third layers:- Electrode: SUPRASTRIP 22 9 3 L 60 x 0.5 mm- Flux: AST 300Welding Process ESW double layersWelding consumables• First layer:- Electrode: SUPRASTRIP 24 13 L 60 x 0.5 mm- Flux: ELT 300S• Second layer:- Electrode: SUPRASTRIP 22 9 3 L 60 x 0.5 mm- Flux: ELT 300SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):* FN (FERITSCOPE) (%)Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo N FN*Base material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 24 13 L 0.020 2.1 0.4 23.9 12.9 0.1 0.045 -SUPRASTRIP 22 9 3 L 0.020 1.5 0.3 23.0 9.4 3.1 0.15 -Surface second layer 0.025 1.2 0.9 22.1 9.4 2.3 0.13 ~45Surface third layer - 3.0 mm 0.025 1.2 0.9 23.1 9.2 2.8 0.14 ~60Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1500 A - Voltage: 24 V• Welding speed: 25 cm/minPhysical properties (indicative values)• Thickness of the deposit: 9.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Ni Mo N FN*Base material 0.18 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 24 13 L 0.020 2.1 0.4 23.9 12.9 0.1 0.045 -SUPRASTRIP 22 9 3 L 0.020 1.5 0.3 23.0 9.4 3.1 0.15 -Surface - 3.0 mm 0.020 1.4 0.6 23.0 9.6 2.6 0.11 ~60* FN (FERITSCOPE) (%)16

Typical OERLIKON solution for Alloy 410SWelding Process ESW single layerWelding consumables• Electrode : SUPRASTRIP 430 60 x 0.5 mm•Flux : ELT 300SBase material• Type P1 according to ASME IX,thickness : 40mmWelding conditions• Preheat : Room temperature• Interpass temperature : 150 °CChemical analysis (typical values):410S410 Ni MoWelding parameters• Current : 1250A Voltage : 24V• Welding speed : 18 cm/minPhysical properties (indicative values)• Thickness of the deposit : 4.2 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Ni Mo NBase material 0.18 1.2 0.4 0.21 - 0.01 -SUPRASTRIP 430 0.04 0.3 0.3 15.5 0.1 0.1 0.040Surface -3 mm 0.06 0.6 0.6 12.9 0.1 0.1 0.045Typical OERLIKON solution for Alloy 410 Ni MoWelding Process SAW multi layersWelding consumables• Electrode: SUPRASTRIP 430 60 x 0.5 mm• Flux: AST 100 BBase material• Type 42CrMo4,thickness: 40 mmWelding conditions• Preheat: 200 °C• Interpass temperature: 250 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 19 cm/minPhysical properties (indicative values)• 4 layers thickness of the deposit: 12 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Ni Mo N HardnessBase material 0.4 1.2 0.4 0.2 0.01 - - -SUPRASTRIP 430 0.05 0.3 0.3 15.4 0.1 0.0 - -Fourth layer 0.07 0.6 0.9 14.0 4.0 1.0 0.04 39 HRC17

Recommended combinations and parametersTypical OERLIKON solutions for Alloy 600600Welding Process SAW double layersWelding consumables• First and second layers:- Electrode: SUPRASTRIP 600 60 x 0.5 mm- Flux: AST 600Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 8.6 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Nb Fe NiBase material 0.18 1.2 0.4 0.21 - - -SUPRASTRIP 600 0.015 3.1 0.3 20.4 3.7 0.25 bal.Surface - 3.0 mm 0.026 3.5 0.8 19.8 2.0 4.9 bal.Welding Process ESW double layersWelding consumables• First and second layers:- Electrode: SUPRASTRIP 600 60 x 0.5 mm- Flux: ELT 600 or ELT 600SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1400 A - Voltage: 24 V• Welding speed: 25 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.8 mm• Deposition rate: 27 kg/hAnalysis C Mn Si Cr Nb Fe NiBase material 0.18 1.2 0.4 0.21 - - -SUPRASTRIP 600 0.015 3.1 0.3 20.4 2.7 0.25 bal.Surface - 3.0 mm 0.026 2.8 0.5 19.5 2.4 4.3 bal.18

Typical OERLIKON solutions for Alloy 625625Welding Process SAW double layersWelding consumables• First and second layers:- Electrode: SUPRASTRIP 625 60 x 0.5 mm- Flux: AST 600Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 8.6 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Mo Nb Ti Fe NiBase material 0.18 1.2 0.4 0.21 - - - - -SUPRASTRIP 625 0.015 0.1 0.1 22.0 9.0 3.6 0.2 0.25 bal.Surface - 3.0 mm 0.020 0.1 0.5 21.0 8.1 3.2 0.07 4.4 bal.Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 625 60 x 0.5 mm• Flux: ELT 625-1Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 25 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Mo Nb Ti Fe NiBase material 0.18 1.2 0.4 0.21 - - - - -SUPRASTRIP 625 0.015 0.1 0.1 22.0 9.0 3.6 0.2 0.25 bal.Surface - 3.0 mm 0.020 0.15 0.20 21.5 8.5 3.3 0.07 7.2 bal.Welding Process ESW double layersWelding consumables• First and second layers:- Electrode: SUPRASTRIP 625 60 x 0.5 mm- Flux: ELT 600 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1400 A - Voltage: 24 V• Welding speed: 20 cm/minPhysical properties (indicative values)• Thickness of the deposit: 7.8 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Mo Nb Ti Fe NiBase material 0.18 1.2 0.4 0.21 - - - - -SUPRASTRIP 625 0.015 0.1 0.1 22.0 9.0 3.6 0.2 0.25 bal.Surface - 3.0 mm 0.020 0.15 0.20 21.5 8.2 3.3 0.07 4.2 bal.19

Recommended combinations and parametersTypical OERLIKON solutions for Alloy 825825Welding Process SAW double layersWelding consumables• First and second layers:- Electrode: SUPRASTRIP 825 60 x 0.5 mm- Flux: AST 600Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 750 A - Voltage: 27 V• Welding speed: 12 cm/minPhysical properties (indicative values)• Thickness of the deposit: 8.6 mm• Deposition rate: 14 kg/hAnalysis C Mn Si Cr Mo Cu Fe NiBase material 0.18 1.2 0.4 0.21 - - - -SUPRASTRIP 825 0.013 0.8 0.3 22.0 3.0 2.0 32 bal.Surface - 3.0 mm 0.023 0.9 0.8 20.1 2.74 1.6 37 bal.Welding Process ESW single layerWelding consumables• Electrode: SUPRASTRIP 825 60 x 0.5 mm• Flux: ELT 825-1Base material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1250 A - Voltage: 25 V• Welding speed: 18 cm/minPhysical properties (indicative values)• Thickness of the deposit: 4.7 mm• Deposition rate: 23 kg/hAnalysis C Mn Si Cr Mo Cu Fe NiBase material 0.18 1.2 0.4 0.21 - - - -SUPRASTRIP 825 0.013 0.8 0.3 22.0 3.0 2.0 32 bal.Surface - 3.0 mm 0.023 0.7 0.7 20.0 2.87 1.6 32 bal.Welding Process ESW double layersWelding consumables• First and second layers:- Electrode: SUPRASTRIP 825 60 x 0.5 mm- Flux: ELT 600 SBase material• Type P1 according to ASME IX,thickness: 40 mmWelding conditions• Preheat: Room temperature• Interpass temperature: 150 °CChemical analysis (typical values):Welding parameters• Current: 1400 A - Voltage: 24 V• Welding speed: 32 cm/minPhysical properties (indicative values)• Thickness of the 7.0 mm• Deposition rate: 28 kg/hAnalysis C Mn Si Cr Mo Cu Fe NiBase material 0.18 1.2 0.4 0.21 - - - -SUPRASTRIP 825 0.013 0.8 0.3 22.0 3.0 2.0 32 bal.Surface - 3.0 mm 0.023 0.7 0.6 21.0 2.85 1.7 33 bal.For alloys Ni6022, Ni6059, Ni60276, please contact OERLIKON service.20

Equipment for <strong>weld</strong> <strong>overlay</strong> applicationsWelding head<strong>Strip</strong> <strong>weld</strong>ing head for <strong>overlay</strong>applications■ This head is designed for electroslagand submerged arc <strong>weld</strong> <strong>overlay</strong> with stripsizes of 30 mm, 60 mm, 90 mm and 120 mm,■ The minimum internal diameter necessarywith this head is 700 mm for circumferentialseams and 550 mm for longitudinal seams.STARMATIC power sources■ Rugged, reliable, suitable foraggressive industrial surroundings,■ Fan-cooled, fitted with thermalcut-out, easy to move using craneor forklift,■ Quick connection to the core of theinstallation by simple and accessibleconnectors,■ Remote controlsystem,■ Function type:1 - SAW direct current (DC)2 - SAW alternatingcurrent (AC)3 - Arc gouging.3A WELDING SYSTEMA new generation of mobile consolecontrol deviceThe 3A Welding System plug & play Mobile Console givesthe operator complete mobility and permits the managementof both machine and process. This new generation user-friendlyinterface is easy to use and operators are rapidly able toprogram the machine efficiently.The multipurpose 3A <strong>weld</strong>ingsystem concept is designed forall arc <strong>weld</strong>ing processes, and theequipment remains upgradablewith the open architecture.Mobile console: browsing on the screenswith a graphic representation of the machine.2006-7812000-357Duty cycleat 100%STARMATIC 1303 DC1 300 A - 44 VPositioning equipment<strong>Oerlikon</strong> provides a full rangeof seamers, column andbooms, rotators, positioners,turntables and mechanisationequipment for everyapplication.STARMATIC 1003 AC/DC1 000 A - 44 VWelding range 2 DC 1 AC - 1 DCPrimary400-440 V 50/60 Hz* 380/400/415 V 50/60 Hz*power supplythree-phasethree-phaseTechnology Thyristors ThyristorsPower at 100%duty cycle99 kVA 98 kVAExternal-staticcharacteristics- flat- drooping■■Net weight 483 kg 540 kg* For other primary power supply three-phase,consult Air Liquide Welding.AC■■2012-176DC■■Advanced mobile console■ Centralised consoledvanced utomatic rchitecture■ Mobile plug (multi point onto the machine)■ User friendly-interfaceAutomatic machine management■ Process management■ Machine cycle control■ Integrated peripheralsArchitecture based on new concept■ Modular and flexible solutions■ Full digital control21

ContactsBELGIUMAIR LIQUIDE WELDING BELGIUM SAZ.I. West Grijpen - Grijpenlaan 5 - 3300 TIENENTel.: +32 16 80 48 20 - Fax: +32 16 78 29 22BRAZILAIR LIQUIDE BRASILAv. das Nações Unidas, 11.541, 19º andarBrooklin Novo - CEP: 04578-000 – SAO PAULO, SPTel.: +55 11 55 09 84 07CHINAAIR LIQUIDE WELDING CHINA REP.OFF.No.185 Tangkai Road,Qiangjiang Economic Development Zone, Hangzhou 310015Tel.: +86 21 64 11 60 69 - Fax: +86 21 64 43 58 97CZECH REPUBLICAIR LIQUIDE CZ S.R.O. - Welding and CuttingPodnikatelská 565 - Areál SVUM - 190 11 PRAHA 9 - BúchoviceTel.: +420 274 023 163 - Fax: +420 274 023 233FRANCEAIR LIQUIDE WELDING FRANCE13, rue d’Épluches - CS 10113 Saint-Ouen l'Aumône95315 CERGY PONTOISE CedexTel.: +33 1 34 21 33 33 - Fax: +33 1 34 21 31 30GERMANYOERLIKON SCHWEISSTECHNIK GmbHIndustriestrasse 12 - D-67304 EISENBERG/PFALZTel.: +49 6351 4760 - Fax: +49 6351 476 335HUNGARYAIR LIQUIDE HUNGARY - Welding & CuttingKrisztina krt. 39/b - H-1013 BUDAPESTTel.: +36 1 339 8650 - Fax: +36 1 339 8649ITALYFRO-AIR LIQUIDE WELDING ITALIA S.p.AVia Torricelli 15/A - 37135 VERONATel.: +39 045 82 91 511 - Fax: +39 045 82 91 536LUXEMBOURGAIR LIQUIDE WELDING LUXEMBOURG S.A.5 rue de la Déportation - BP 1385 - L-1415 LUXEMBOURGTel.: +352 48 54 56 - Fax: +352 48 54 57MALAYSIASAF-OERLIKON MALAYSIA SDN BHD - No 10, Jalan TPP 5/1Taman Perindustrian Puchong - 47100 PUCHONG, SELANGORTel.: +603 8060 8638 - Fax: +603 8061 620NETHERLANDSAIR LIQUIDE WELDING NETHERLANDSRudonk 6 B - NL 4824 AJ BREDATel.: +31 76 541 00 80 - Fax: +31 76 541 58 96POLANDAIR LIQUIDE WELDING POLSKA - SP. Z.o.oUL. Porcelanowa 10 - 40-246 KATOWICETel.: +48 32 609 04 50 - Fax: +48 32 609 04 60ALW International DevelopmentDepartment ItalyFRO-AIR LIQUIDE WELDING ITALIA S.p.AVia Torricelli15/A37135 VeronaTel.: +39 045 82 91 511 - Fax: +39 045 82 91 536Contacts for other countries:www.airliquide.comPORTUGALAIR LIQUIDE SOLDADURARua Dr. Antonio Loureiro Borges nº 4 - 1º andarCP: 1.495-131 - Miraflores - ALGÉSTel: +351 21 416 4900 - Fax: +351 21 41 69 40ROMANIADUCTILAleea Industriilor Nr 1 - 120224 BUZAUTel.: +40 238 722 058 - Fax: +40 238 716 861RUSSIAAIR LIQUIDE WELDING17 Vorontsovskaya Str. - 109147 MOSCOWTel.: +7 495 641 28 98 - Fax: +7 495 641 28 91SCANDINAVIAOERLIKON SKANDINAVIEN ABKrossverksgatan 7 - 216 16 LIMHAMNTel.: +46 (0)40 670 15 00 - Fax: +46 (0)40 670 15 01SLOVAKIAAIR LIQUIDE WELDING CENTRAL EUROPE S.R.O.Hlohovecká 6 - 951 41 NITRA - LUŽIANKYTel.: +421 37 692 4610 - Fax: +421 37 651 28 04SPAINOERLIKON SOLDADURA SAPoligono Industrial la Noria Carretera de CastellonKm-15,500 - 50730 El Burgo de Ebro - ZARAGOZATel.: +34 976 10 47 00 - Fax: +34 976 10 42 67SWITZERLANDOERLIKON SCHWEISSTECHNIK AGMandachstrasse 54 - CH 8155 NIEDERHASLITel.:+41 44 3076 111 - Fax: +41 44 3076 112THAILANDAIR LIQUIDE WELDING THAILAND Co. Ltd.5 Panyaramindra Road - KHANNAYAO,BANGKOK 10230Tel.: +66 29 43 2250 - Fax: +66 29 43 2256UAEAIR LIQUIDE WELDING MIDDLE EAST FZEJebel Ali free zone warehouse No. FZS1AH05P.O. BOX 18734 - Jebel Ali - DUBAITel.: +971(0)48861606 - Fax: +971(0)48861608U. K.AIR LIQUIDE WELDING LtdLow March / London Road - DAVENTRY - Northants NN11 4SDTel.: +44 1 327 70 55 11 - Fax: +44 1 327 70 13 10UKRAINEAIR LIQUIDE WELDING UKRAINE, Llc.199, Moskovski avenue, office 339 - 61037 KHARKOVTel.: +38 (057) 728 08 52 - Fax : +38 (057) 728 08 53ALW International DevelopmentDepartment FranceAIR LIQUIDE WELDING FRANCE13, rue d’Epluches - CS 10113 Saint Ouen l’Aumône95315 Cergy-Pontoise CedexTel.: +33 1 34 21 33 33- Fax: +33 1 30 37 19 73© Air Liquide Welding - W000377012 - 01/2013 - Ed.1 - H1 - PLDB 7444 - Crédit photos: FotoliaAir Liquide Welding reserves the right to modify its products without prior notice. The information contained in this document is designed to help the user in the choiceof product. The user should check that the product chosen is suited to the application.Air Liquide is the world leader in gases for industry, health and the environment, and is present in over 80 countries with 46 200 employees Oxygen, nitrogen,hydrogen and rare gases have been at the core of Air Liquide’s activities since its creation in 1902. Using these molecules, Air Liquide continuously reinventsits business, anticipating the needs of current and future markets. The Group innovates to enable progress, to achieve dynamic growth and a consistent performance.Air Liquide combines many products and technologies to develop valuable applications and services not only for its customers but also for society.