Branchenführer Innovative Biowerkstoffe (BIB 2010) - Plasticker

Branchenführer Innovative Biowerkstoffe (BIB 2010) - Plasticker

Branchenführer Innovative Biowerkstoffe (BIB 2010) - Plasticker

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

64<br />

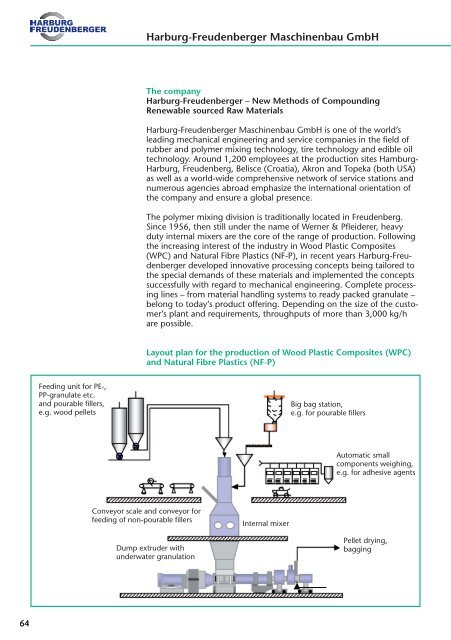

Feeding unit for PE-,<br />

PP-granulate etc.<br />

and pourable fillers,<br />

e.g. wood pellets<br />

Harburg-Freudenberger Maschinenbau GmbH<br />

The company<br />

Harburg-Freudenberger – New Methods of Compounding<br />

Renewable sourced Raw Materials<br />

Harburg-Freudenberger Maschinenbau GmbH is one of the world’s<br />

leading mechanical engineering and service companies in the field of<br />

rubber and polymer mixing technology, tire technology and edible oil<br />

technology. Around 1,200 employees at the production sites Hamburg-<br />

Harburg, Freudenberg, Belisce (Croatia), Akron and Topeka (both USA)<br />

as well as a world-wide comprehensive network of service stations and<br />

numerous agencies abroad emphasize the international orientation of<br />

the company and ensure a global presence.<br />

The polymer mixing division is traditionally located in Freudenberg.<br />

Since 1956, then still under the name of Werner & Pfleiderer, heavy<br />

duty internal mixers are the core of the range of production. Following<br />

the increasing interest of the industry in Wood Plastic Composites<br />

(WPC) and Natural Fibre Plastics (NF-P), in recent years Harburg-Freudenberger<br />

developed innovative processing concepts being tailored to<br />

the special demands of these materials and implemented the concepts<br />

successfully with regard to mechanical engineering. Complete processing<br />

lines – from material handling systems to ready packed granulate –<br />

belong to today’s product offering. Depending on the size of the customer’s<br />

plant and requirements, throughputs of more than 3,000 kg/h<br />

are possible.<br />

Layout plan for the production of Wood Plastic Composites (WPC)<br />

and Natural Fibre Plastics (NF-P)<br />

Conveyor scale and conveyor for<br />

feeding of non-pourable fillers<br />

Dump extruder with<br />

underwater granulation<br />

Internal mixer<br />

Big bag station,<br />

e.g. for pourable fillers<br />

Automatic small<br />

components weighing,<br />

e.g. for adhesive agents<br />

Pellet drying,<br />

bagging