SMEC Gesamtkatalog

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

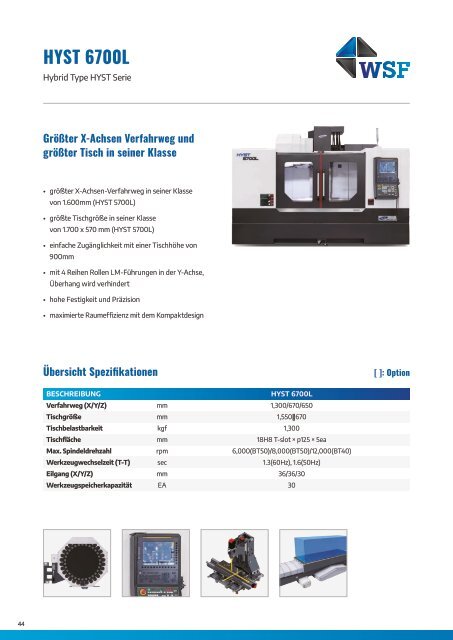

HYST 6700L<br />

Hybrid Type HYST Serie<br />

HYbrid STrong!<br />

Größter X-Achsen Verfahrweg und<br />

größter Tisch in seiner Klasse<br />

• größter X-Achsen-Verfahrweg in seiner Klasse<br />

von 1.600mm (HYST 5700L)<br />

• größte Tischgröße in seiner Klasse<br />

von 1.700 x 570 mm (HYST 5700L)<br />

• einfache Zugänglichkeit mit einer Tischhöhe von<br />

900mm<br />

• mit 4 Reihen Rollen LM-Führungen in der Y-Achse,<br />

Überhang wird verhindert<br />

Hybrid Machining Center (X / Y-axis LM Guide, Z-axis Box Guide)<br />

• hohe Festigkeit und Präzision<br />

Z-axis Box Guide enhances rigidity and<br />

enables heavy duty cutting<br />

X / Y-axis with LM Guides improve travel precision<br />

and significantly reduces non-cutting time<br />

• maximierte Raumeffizienz mit dem Kompaktdesign<br />

Machine Tools<br />

44<br />

Übersicht Spezifikationen<br />

HYST Series<br />

VERTICAL MACHINING CENTER<br />

ATC / Magazine<br />

BESCHREIBUNG<br />

HYST 6700L<br />

rong!<br />

Verfahrweg (X/Y/Z) mm 1,300/670/650<br />

Tischgröße mm 1,550x670<br />

Tischbelastbarkeit kgf 1,300<br />

HYST Series<br />

Tischfläche mm 18H8 T-slot × p125 × 5ea<br />

Max. Spindeldrehzahl rpm 6,000(BT50)/8,000(BT50)/12,000(BT40)<br />

Werkzeugwechselzeit (T-T) sec 1.3(60Hz), 1.6(50Hz)<br />

Eilgang (X/Y/Z) mm 36/36/30<br />

Werkzeugspeicherkapazität EA 30<br />

VERTICAL MACHINING CENTER<br />

ATC / Magazine<br />

ATC Magazine<br />

HYST Series<br />

VERTICAL MACHINING CENTER<br />

Machine Design<br />

Designed with a standard 30 tool magazine with short travel<br />

distance to enable quick tool changes<br />

Fast and errorless tool changes are made possible using the<br />

memory random technique and double arm type tool changer,<br />

minimizing non-cutting time<br />

HYST 5700L / HYST 6700 BT40<br />

Tool storage capacity : 30<br />

Tool-to-tool time : 1.3(60Hz)sec<br />

Max. tool dia.(adjacent empty) : 80(125)mm<br />

Max. tool length : 300mm<br />

Max. tool weight : 8kg<br />

HYST 6700 BT50<br />

Tool storage capacity : 30<br />

Model<br />

Tool-to-tool time : 2.45(60Hz)sec<br />

Z-Axis<br />

Y-Axis<br />

X-Axis<br />

Travel(mm)<br />

X-axis Y-axis Z-axis<br />

HYST 5700L 1,600 570 520<br />

HYST 6700 1,300 670 650<br />

Bucket Option<br />

Eco-Friendly Table Chip Disposal<br />

The application of Roller Type LM Guides to<br />

X and Y axes minimizes the noise created<br />

during travel and the superior accel / decel<br />

minimizes the non-cutting time<br />

The application of Box Guide to only the<br />

Z-axis minimizes backlash while minimizing<br />

the disadvantages that other fully box-guide<br />

machines have with horizontal travel (X/Y).<br />

Coil conveyor 2set<br />

Highly Rigid Saddle with no X-axis Overhang<br />

The highly rigid saddle enables reliable machining of<br />

various materials and is suitable for long materials<br />

4 Row Y-axis Guide Way Bed (HYST 5700L)<br />

Overhang is minimized with the 4 rows of LM Guides<br />

supporting the Y-axis with the widest in class span<br />

Z-axis High Rigidity Arched Column<br />

Machine Tools<br />

The arched column ensures Chip high Conveyor<br />

rigidity and high<br />

Option<br />

precision machining performance<br />

170<br />

Automated Coolant Supply<br />

Quill-Type Head stock<br />

230<br />

[ ]: Option<br />

Hybrid<br />

ATC Magazine<br />

Ty<br />

Designed with a standard 30 tool magazine with short travel<br />

distance to enable quick tool changes<br />

Fast and errorless tool changes are made possible using the<br />

memory random technique and double arm type tool changer,<br />

minimizing non-cutting time<br />

5700L / 6700 BT40<br />

Tool storage capacity : 30<br />

Tool-to-tool time : 1.3(60Hz)sec<br />

HYST Max. tool dia.(adjacent empty) 570<br />

: 80(125)mm<br />

Max. tool length : 300mm<br />

Max. tool weight : 8kg<br />

HYST 6700 BT50<br />

Largest in class<br />

Tool storage capacity : 30<br />

X-axis t<br />

Tool-to-tool time : 2.45(60Hz)sec<br />

- largest Max. in tool class dia.(adjacent X-axis empty) : 100(195)mm travel o<br />

Max. tool length : 300mm<br />

Max. tool weight : 15kg<br />

- largest in class table size of 1<br />

- easy user accessibility with a<br />

Spindle Table size and Table loading capacity were<br />

Complete chip discharge through the<br />

increased to support larger work area<br />

The<br />

series of chip disposal processes by the by 4<br />

bear<br />

HYST 5700L coolant nozzle, bed flush, coil conveyor mac<br />

- with 4 rows mini<br />

Table size and<br />

of Roller LM-Gu<br />

: 1,700×570mm<br />

chip conveyor<br />

heat<br />

Table surface : 18H8×p125×4ea<br />

Dir<br />

HYS<br />

- high strength Table loading capacity and : 1,000kgf high prec<br />

Max<br />

- the large, rectangular S/GUARD design and re<br />

HYST 6700<br />

Pow<br />

coolant tank ensures easy chip removal<br />

Torq<br />

Table size : 1,550×670mm<br />

- maximized space efficiency<br />

Travel (X/Y/Z)<br />

- using bed flushing, complete chip disposal off th<br />

HYS<br />

Table surface : of 18H8×p125×5ea<br />

the bed<br />

Max<br />

Table loading - the chip capacity conveyor : 1,300kgf<br />

can be installed in either the left Pow<br />

right direction according to the required layout f<br />

Torq<br />

efficient chip disposal<br />

Category<br />

mm<br />

Ge<br />

HYS<br />

Ma<br />

Pow<br />

Torq<br />

JAC