Complete issue (pdf, 7520.08 MB, EN) - GIZ

Complete issue (pdf, 7520.08 MB, EN) - GIZ

Complete issue (pdf, 7520.08 MB, EN) - GIZ

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

akzeNTUIerT<br />

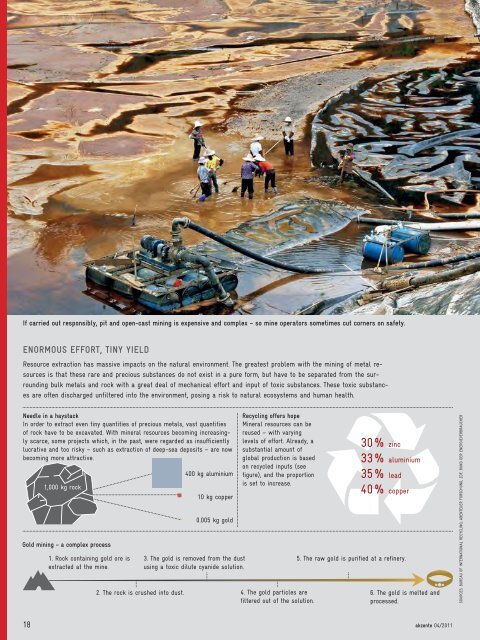

If carried out responsibly, pit and open-cast mining is expensive and complex – so mine operators sometimes cut corners on safety.<br />

eNOrmOUS eFFOrT, TINy yIeld<br />

Resource extraction has massive impacts on the natural environment. The greatest problem with the mining of metal resources<br />

is that these rare and precious substances do not exist in a pure form, but have to be separated from the surrounding<br />

bulk metals and rock with a great deal of mechanical effort and input of toxic substances. These toxic substances<br />

are often discharged unfiltered into the environment, posing a risk to natural ecosystems and human health.<br />

Needle in a haystack recycling offers hope<br />

In order to extract even tiny quantities of precious metals, vast quantities<br />

of rock have to be excavated. With mineral resources becoming increasingly<br />

scarce, some projects which, in the past, were regarded as insufficiently<br />

lucrative and too risky – such as extraction of deepsea deposits – are now<br />

becoming more attractive.<br />

Gold mining – a complex process<br />

18<br />

1,000 kg rock<br />

1. Rock containing gold ore is<br />

extracted at the mine.<br />

400 kg aluminium<br />

10 kg copper<br />

0.005 kg gold<br />

3. The gold is removed from the dust<br />

using a toxic dilute cyanide solution.<br />

Mineral resources can be<br />

reused – with varying<br />

levels of effort. Already, a<br />

substantial amount of<br />

global production is based<br />

on recycled inputs (see<br />

figure), and the proportion<br />

is set to increase.<br />

30 % zinc<br />

33 % aluminium<br />

35 % lead<br />

40 % copper<br />

5. The raw gold is purified at a refinery.<br />

2. The rock is crushed into dust. 4. The gold particles are<br />

6. The gold is melted and<br />

filtered out of the solution.<br />

processed.<br />

akzente 04/2011<br />

SOURCES: BUREAU OF INTERNATIONAL RECYCLING; AB<strong>EN</strong>TEUER FORSChUNG, ZDF; BUND DER <strong>EN</strong>ERGIEVERBRAUChER