tm 55-2350-224-14 m113 family of vehicles (m113a2 ... - 1st-cav.com

tm 55-2350-224-14 m113 family of vehicles (m113a2 ... - 1st-cav.com

tm 55-2350-224-14 m113 family of vehicles (m113a2 ... - 1st-cav.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

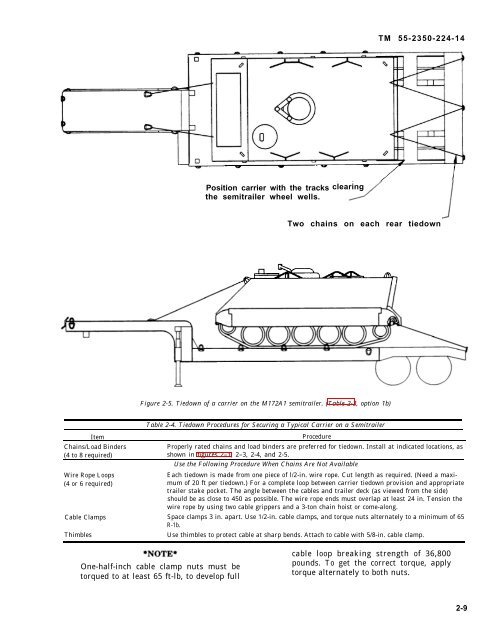

Position carrier with the tracks<br />

the semitrailer wheel wells.<br />

clearing<br />

TM <strong>55</strong>-<strong>2350</strong>-<strong>224</strong>-<strong>14</strong><br />

Two chains on each rear tiedown<br />

Figure 2-5. Tiedown <strong>of</strong> a carrier on the M172A1 semitrailer. (Table 2-3, option 1b)<br />

Table 2-4. Tiedown Procedures for Securing a Typical Carrier on a Semitrailer<br />

Item Procedure<br />

Chains/Load Binders Properly rated chains and load binders are preferred for tiedown. Install at indicated locations, as<br />

(4 to 8 required) shown in figures 2–1, 2–3, 2-4, and 2-5.<br />

Use the Following Procedure When Chains Are Not Available<br />

Wire Rope Loops Each tiedown is made from one piece <strong>of</strong> l/2-in. wire rope. Cut length as required. (Need a maxi-<br />

(4 or 6 required)<br />

mum <strong>of</strong> 20 ft per tiedown.) For a <strong>com</strong>plete loop between carrier tiedown provision and appropriate<br />

trailer stake pocket. The angle between the cables and trailer deck (as viewed from the side)<br />

should be as close to 450 as possible. The wire rope ends must overlap at least 24 in. Tension the<br />

wire rope by using two cable grippers and a 3-ton chain hoist or <strong>com</strong>e-along.<br />

Cable Clamps Space clamps 3 in. apart. Use 1/2-in. cable clamps, and torque nuts alternately to a minimum <strong>of</strong> 65<br />

R-1b.<br />

Thimbles Use thimbles to protect cable at sharp bends. Attach to cable with 5/8-in. cable clamp.<br />

One-half-inch cable clamp nuts must be<br />

torqued to at least 65 ft-lb, to develop full<br />

cable loop breaking strength <strong>of</strong> 36,800<br />

pounds. To get the correct torque, apply<br />

torque alternately to both nuts.<br />

2-9