Autoconer 338 – Winding Technology. Multi-Optionality, Know-how ...

Autoconer 338 – Winding Technology. Multi-Optionality, Know-how ...

Autoconer 338 – Winding Technology. Multi-Optionality, Know-how ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Autoconer</strong> packages for Twisting<br />

and Assembly <strong>Winding</strong>.<br />

4<br />

>1<br />

>2<br />

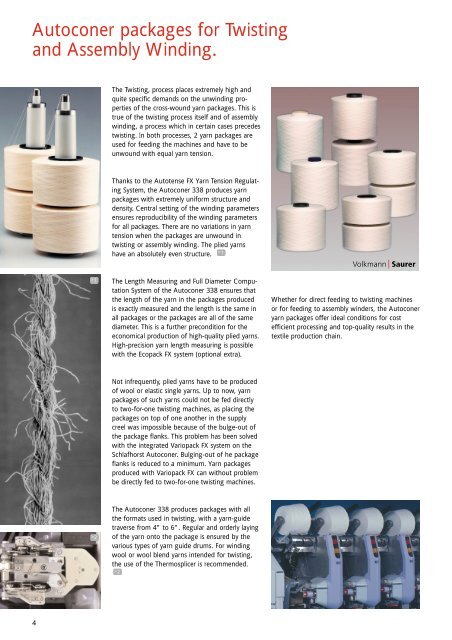

The Twisting, process places extremely high and<br />

quite specific demands on the unwinding properties<br />

of the cross-wound yarn packages. This is<br />

true of the twisting process itself and of assembly<br />

winding, a process which in certain cases precedes<br />

twisting. In both processes, 2 yarn packages are<br />

used for feeding the machines and have to be<br />

unwound with equal yarn tension.<br />

Thanks to the Autotense FX Yarn Tension Regulating<br />

System, the <strong>Autoconer</strong> <strong>338</strong> produces yarn<br />

packages with extremely uniform structure and<br />

density. Central setting of the winding parameters<br />

ensures reproducibility of the winding parameters<br />

for all packages. There are no variations in yarn<br />

tension when the packages are unwound in<br />

twisting or assembly winding. The plied yarns<br />

have an absolutely even structure. >1<br />

The Length Measuring and Full Diameter Computation<br />

System of the <strong>Autoconer</strong> <strong>338</strong> ensures that<br />

the length of the yarn in the packages produced<br />

is exactly measured and the length is the same in<br />

all packages or the packages are all of the same<br />

diameter. This is a further precondition for the<br />

economical production of high-quality plied yarns.<br />

High-precision yarn length measuring is possible<br />

with the Ecopack FX system (optional extra).<br />

Not infrequently, plied yarns have to be produced<br />

of wool or elastic single yarns. Up to now, yarn<br />

packages of such yarns could not be fed directly<br />

to two-for-one twisting machines, as placing the<br />

packages on top of one another in the supply<br />

creel was impossible because of the bulge-out of<br />

the package flanks. This problem has been solved<br />

with the integrated Variopack FX system on the<br />

Schlafhorst <strong>Autoconer</strong>. Bulging-out of he package<br />

flanks is reduced to a minimum. Yarn packages<br />

produced with Variopack FX can without problem<br />

be directly fed to two-for-one twisting machines.<br />

The <strong>Autoconer</strong> <strong>338</strong> produces packages with all<br />

the formats used in twisting, with a yarn-guide<br />

traverse from 4" to 6". Regular and orderly laying<br />

of the yarn onto the package is ensured by the<br />

various types of yarn guide drums. For winding<br />

wool or wool blend yarns intended for twisting,<br />

the use of the Thermosplicer is recommended.<br />

>2<br />

Whether for direct feeding to twisting machines<br />

or for feeding to assembly winders, the <strong>Autoconer</strong><br />

yarn packages offer ideal conditions for cost<br />

efficient processing and top-quality results in the<br />

textile production chain.