Bulletin 1/2008 - Siempelkamp

Bulletin 1/2008 - Siempelkamp

Bulletin 1/2008 - Siempelkamp

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Powered by <strong>Siempelkamp</strong>: complete<br />

solution package from Krefeld in<br />

Africa<br />

The supporting pillars for the complete<br />

concept of this state-of-the-art and highly<br />

productive plant for wood-based products<br />

on the African continent are <strong>Siempelkamp</strong>’s<br />

products and solutions. The contract for the<br />

supply of a complete particleboard line for<br />

the plant in Ugie was signed by PG Bison<br />

and <strong>Siempelkamp</strong> in February of 2006. The<br />

planning and engineering were carried out<br />

by <strong>Siempelkamp</strong>’s Belgian subsidiary Sicoplan.<br />

Several other <strong>Siempelkamp</strong> Group<br />

companies followed in Sicoplan’s footsteps.<br />

The scope of supply included the<br />

woodyard, debarking plant, chippers, and<br />

extractors. Furthermore, <strong>Siempelkamp</strong><br />

delivered screens, knife-ring flakers,<br />

screens for core layer and surface layer<br />

classification, the resinating system and<br />

dry particle bins.<br />

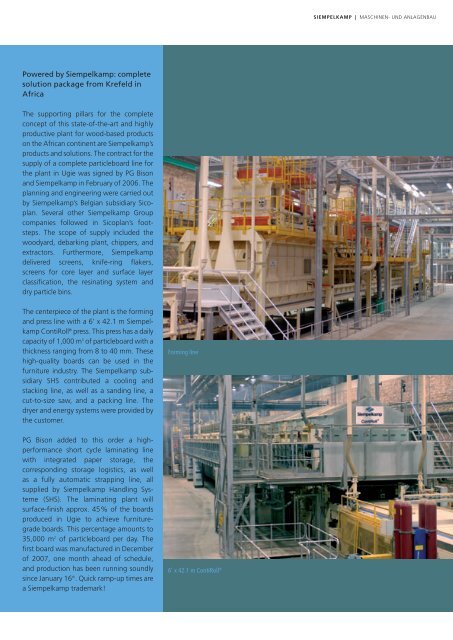

The centerpiece of the plant is the forming<br />

and press line with a 6’ x 42.1 m <strong>Siempelkamp</strong><br />

ContiRoll ® press. This press has a daily<br />

capacity of 1,000 m 3 of particleboard with a<br />

thickness ranging from 8 to 40 mm. These<br />

high-quality boards can be used in the<br />

furniture industry. The <strong>Siempelkamp</strong> subsidiary<br />

SHS contributed a cooling and<br />

stacking line, as well as a sanding line, a<br />

cut-to-size saw, and a packing line. The<br />

dryer and energy systems were provided by<br />

the customer.<br />

PG Bison added to this order a highperformance<br />

short cycle laminating line<br />

with integrated paper storage, the<br />

corresponding storage logistics, as well<br />

as a fully automatic strapping line, all<br />

supplied by <strong>Siempelkamp</strong> Handling Systeme<br />

(SHS). The laminating plant will<br />

surface-finish approx. 45% of the boards<br />

produced in Ugie to achieve furnituregrade<br />

boards. This percentage amounts to<br />

35,000 m 2 of particleboard per day. The<br />

first board was manufactured in December<br />

of 2007, one month ahead of schedule,<br />

and production has been running soundly<br />

since January 16 th . Quick ramp-up times are<br />

a <strong>Siempelkamp</strong> trademark!<br />

Forming line<br />

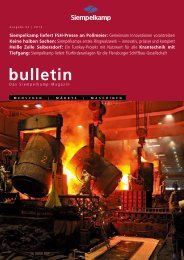

6’ x 42.1 m ContiRoll ®<br />

SIEMPELKAMP | MASCHINEN- UND ANLAGENBAU