- Page 1 and 2: Robot Builder’s Sourcebook

- Page 3 and 4: Robot Builder’s Sourcebook Gordon

- Page 5 and 6: Dedication For Lane. Continuing the

- Page 7 and 8: Contents For more information about

- Page 9 and 10: viii contents Electronics-Sound & M

- Page 11 and 12: x contents Robots-Walking 544 Senso

- Page 13 and 14: xii introduction Those that are lis

- Page 15 and 16: xiv Introduction • Newsgroup read

- Page 17 and 18: xvi how to use the source listings

- Page 19 and 20: This page intentionally left blank.

- Page 21 and 22: 2 SEE ALSO: Actuators Motor Control

- Page 23 and 24: 4 Actuators-motion products � (83

- Page 25 and 26: 6 Actuators-motion products � sal

- Page 27 and 28: 8 Actuators-motion products What's

- Page 29 and 30: 10 Actuators-motion products What

- Page 31 and 32: 12 Actuators-motion products � (8

- Page 33 and 34: 14 + Actuators-Motors Motors that t

- Page 35 and 36: 16 Actuators-motors Compumotor / Pa

- Page 37 and 38: 18 Actuators-motors See other techn

- Page 39 and 40: 20 Actuators-motors Bear in mind th

- Page 41 and 42: 22 Actuators-motors Cross Compariso

- Page 43 and 44: 24 Actuators-motors There is some d

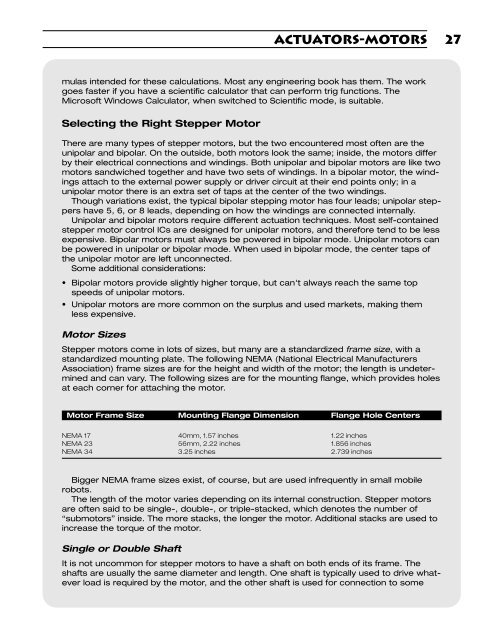

- Page 45: 26 Actuators-motors into the box an

- Page 49 and 50: 30 Actuators-motors � http://www.

- Page 51 and 52: 32 Actuators-motors Micromech 20218

- Page 53 and 54: 34 Actuators-motors you can find ma

- Page 55 and 56: 36 Superior Electric 202628 383 Mid

- Page 57 and 58: 38 Actuators-motors High powered Et

- Page 59 and 60: 40 Actuators-pneumatic In Europe th

- Page 61 and 62: 42 Actuators-pneumatic • Mosier-p

- Page 63 and 64: 44 Actuators-shape memory alloys Bu

- Page 65 and 66: 46 Bar coding �Bar Coding Bar cod

- Page 67 and 68: 48 Bar coding Using a Brother P-Tou

- Page 69 and 70: 50 Bar coding � info@symbol.com

- Page 71 and 72: 52 batteries and power Battery Mart

- Page 73 and 74: 54 batteries and power Chemical Mak

- Page 75 and 76: 56 batteries and power Common Batte

- Page 77 and 78: 58 batteries and power bly need reg

- Page 79 and 80: 60 batteries and power Pico Electro

- Page 81 and 82: 62 books { Books Books are still th

- Page 83 and 84: 64 books-robotics Robotics Universe

- Page 85 and 86: 66 books-technical U.S. Government

- Page 87 and 88: 68 books-technical Google.com searc

- Page 89 and 90: 70 books-technical Stiquito: Advanc

- Page 91 and 92: 72 books-technical Robotics Essays

- Page 93 and 94: 74 books-technical A small but high

- Page 95 and 96: 76 books-technical Entry-level text

- Page 97 and 98:

78 books-technical �CMOS Cookbook

- Page 99 and 100:

80 books-technical Use of a PC Prin

- Page 101 and 102:

82 books-technical with age just as

- Page 103 and 104:

84 communications-infrared Help—M

- Page 105 and 106:

86 communications-rf Bluetooth 2041

- Page 107 and 108:

88 communications-rf Robot Radio Li

- Page 109 and 110:

90 communications-rf North Country

- Page 111 and 112:

92 communications-rf RF Digital Cor

- Page 113 and 114:

94 competitions nize other opponent

- Page 115 and 116:

96 SEE ALSO: competitions-combat Co

- Page 117 and 118:

98 competitions-combat Movers and S

- Page 119 and 120:

100 competitions-entrant “Home of

- Page 121 and 122:

102 competitions-other � http://w

- Page 123 and 124:

104 competitions-soccer & ball play

- Page 125 and 126:

106 computers V Computers Listings

- Page 127 and 128:

108 computers-data acquisition Prai

- Page 129 and 130:

110 computers-i/o Of Inputs and Out

- Page 131 and 132:

112 • Opto I/O • Relay • Digi

- Page 133 and 134:

114 computers-single board computer

- Page 135 and 136:

116 computers-single board computer

- Page 137 and 138:

118 computers-single board computer

- Page 139 and 140:

120 distributor/wholesaler @ Distri

- Page 141 and 142:

122 distributor/wholesaler-industri

- Page 143 and 144:

124 distributor/wholesaler-industri

- Page 145 and 146:

126 distributor/wholesaler-industri

- Page 147 and 148:

128 distributor/wholesaler-other co

- Page 149 and 150:

130 @ Electronics This section enco

- Page 151 and 152:

132 electronics-circuit examples Bo

- Page 153 and 154:

134 electronics-circuit examples

- Page 155 and 156:

136 electronics-display Sample code

- Page 157 and 158:

138 electronics-display � info@se

- Page 159 and 160:

140 Of course, you're not limited t

- Page 161 and 162:

142 electronics-pcb-design � +61

- Page 163 and 164:

144 electronics-pcb-design Custom (

- Page 165 and 166:

146 electronics-pcb-production bugs

- Page 167 and 168:

148 SEE ALSO: electronics-soldering

- Page 169 and 170:

150 electronics-sound & music Makin

- Page 171 and 172:

152 electronics-sound & music • F

- Page 173 and 174:

154 electronics-sound & music SoftV

- Page 175 and 176:

156 Entertainment { Entertainment W

- Page 177 and 178:

158 Entertainment-Art Movie Poster

- Page 179 and 180:

160 Entertainment-books & movies Fo

- Page 181 and 182:

162 Entertainment-books & movies Wh

- Page 183 and 184:

164 the physical traits of the fast

- Page 185 and 186:

166 fasteners American Bolt and Scr

- Page 187 and 188:

168 fasteners � (616) 748-1246

- Page 189 and 190:

170 fasteners McFeely's Square Driv

- Page 191 and 192:

172 fasteners � (724) 452-8003

- Page 193 and 194:

174 fasteners Wicks Aircraft Supply

- Page 195 and 196:

176 fests and shows Hoosier Hills H

- Page 197 and 198:

178 internet-bulletin board/mailing

- Page 199 and 200:

180 Yahoo Groups: Rug Warrior 20374

- Page 201 and 202:

182 internet-EDU/GOVERNMENT LABS Au

- Page 203 and 204:

184 internet-EDU/GOVERNMENT LABS Co

- Page 205 and 206:

186 internet-EDU/GOVERNMENT LABS ma

- Page 207 and 208:

188 internet-EDU/GOVERNMENT LABS ar

- Page 209 and 210:

190 internet-EDU/GOVERNMENT LABS Ro

- Page 211 and 212:

192 internet-informational Autonomo

- Page 213 and 214:

194 internet-informational The Robo

- Page 215 and 216:

196 internet-informational Omniscie

- Page 217 and 218:

198 internet-informational All aboa

- Page 219 and 220:

200 internet-links Open Directory P

- Page 221 and 222:

202 Meccano Sources 202309 http://w

- Page 223 and 224:

204 internet-personal web page edge

- Page 225 and 226:

206 internet-personal web page G-Bo

- Page 227 and 228:

208 internet-personal web page Roga

- Page 229 and 230:

210 internet-plans & Guides Cricket

- Page 231 and 232:

212 One of the better instructional

- Page 233 and 234:

214 Internet-research Searching for

- Page 235 and 236:

216 internet-research stock of over

- Page 237 and 238:

218 internet-research ToyDirectory.

- Page 239 and 240:

220 internet-search Google, the kin

- Page 241 and 242:

222 internet-search Searching Wisel

- Page 243 and 244:

224 internet-search At the time of

- Page 245 and 246:

226 internet-search Google Search:

- Page 247 and 248:

228 Of course, you can view the arc

- Page 249 and 250:

230 Newsgroups: rec.crafts .metalwo

- Page 251 and 252:

232 internet-usenet newsgroups Web

- Page 253 and 254:

234 { Journals and Magazines Whethe

- Page 255 and 256:

236 journals and magazines From the

- Page 257 and 258:

238 journals and magazines Science

- Page 259 and 260:

240 kits t Kits A great way to lear

- Page 261 and 262:

242 kits-electronic Electronic Rain

- Page 263 and 264:

244 kits-electronic � +44 (0) 207

- Page 265 and 266:

246 kits-electronic Ozitronics 2026

- Page 267 and 268:

248 kits-robotics You’ll find tha

- Page 269 and 270:

250 I LEGO LEGO has become such an

- Page 271 and 272:

252 lego-general LEGO can be used a

- Page 273 and 274:

254 lego-MINDSTORMS Under the Hood

- Page 275 and 276:

256 lego-MINDSTORMS How to retrofit

- Page 277 and 278:

258 lego-MINDSTORMS RCX IO Extender

- Page 279 and 280:

260 machine framing Futura Industri

- Page 281 and 282:

262 machine framing Aluminum extrus

- Page 283 and 284:

264 machine framing Machine Framing

- Page 285 and 286:

266 � Manufacturer The following

- Page 287 and 288:

268 Manufacturer-components � (40

- Page 289 and 290:

270 Manufacturer-glues & adhesives

- Page 291 and 292:

272 Manufacturer-semiconductors •

- Page 293 and 294:

274 Manufacturer-semiconductors Ela

- Page 295 and 296:

276 Manufacturer-semiconductors bus

- Page 297 and 298:

278 Manufacturer-semiconductors Zar

- Page 299 and 300:

280 Manufacturer-tools Dremel 20213

- Page 301 and 302:

282 Manufacturer-tools � (781) 89

- Page 303 and 304:

284 materials Graybar Electric Comp

- Page 305 and 306:

286 materials The MSC Web page. Out

- Page 307 and 308:

288 WESCO International, Inc. 20397

- Page 309 and 310:

290 materials-fiberglass & carbon c

- Page 311 and 312:

292 materials-fiberglass & carbon c

- Page 313 and 314:

294 materials-foam Jim Allred Taxid

- Page 315 and 316:

296 materials-foam Sign Foam makes

- Page 317 and 318:

298 materials-lighting Sequencing e

- Page 319 and 320:

300 materials-lighting example, the

- Page 321 and 322:

302 � Materials-Metal Some lament

- Page 323 and 324:

304 materials-metal Show your patri

- Page 325 and 326:

306 materials-metal � (765) 675-8

- Page 327 and 328:

308 materials-metal Extensive listi

- Page 329 and 330:

310 materials-metal Small aircraft

- Page 331 and 332:

312 materials-other � (800) 355-2

- Page 333 and 334:

314 materials-other Useful sizes:

- Page 335 and 336:

316 materials-other Gummy Transfer

- Page 337 and 338:

318 materials-paper & plastic lamin

- Page 339 and 340:

320 materials-paper & plastic lamin

- Page 341 and 342:

322 materials-plastics Types of Pla

- Page 343 and 344:

324 materials-plastics and mold mak

- Page 345 and 346:

326 materials-plastics Plasti-kote

- Page 347 and 348:

328 materials-plastics If you’re

- Page 349 and 350:

330 materials-plastics � (614) 88

- Page 351 and 352:

332 materials-plastics � http://w

- Page 353 and 354:

334 • 1- to 2-inch diameter light

- Page 355 and 356:

336 materials-transfer film � mic

- Page 357 and 358:

338 materials-transfer film � htt

- Page 359 and 360:

340 microcontrollers-hardware � +

- Page 361 and 362:

342 microcontrollers-hardware The B

- Page 363 and 364:

344 microcontrollers-hardware Also

- Page 365 and 366:

346 microcontrollers-hardware Embed

- Page 367 and 368:

348 microcontrollers-hardware The B

- Page 369 and 370:

350 microcontrollers-hardware Suppo

- Page 371 and 372:

352 microcontrollers-hardware of wi

- Page 373 and 374:

354 microcontrollers-hardware objec

- Page 375 and 376:

356 microcontrollers-hardware Peter

- Page 377 and 378:

358 microcontrollers-hardware � (

- Page 379 and 380:

360 microcontrollers-programming

- Page 381 and 382:

362 microcontrollers-programming Se

- Page 383 and 384:

364 microcontrollers-software Crown

- Page 385 and 386:

366 + Motor Control In this section

- Page 387 and 388:

368 • System Calculations-Linear

- Page 389 and 390:

370 motor control � (858) 450-102

- Page 391 and 392:

372 motor control J R Kerr 203854 9

- Page 393 and 394:

374 motor control Informational pag

- Page 395 and 396:

376 motor control � (973) 423-239

- Page 397 and 398:

378 motor control robot, but also s

- Page 399 and 400:

380 outside-of-the-box �Outside-o

- Page 401 and 402:

382 Portal xPortal The listings in

- Page 403 and 404:

384 Portal-programming Pekee.fr htt

- Page 405 and 406:

386 Portal-robotics Robot Channel,

- Page 407 and 408:

388 power transmission � sales@be

- Page 409 and 410:

390 power transmission Roller Chain

- Page 411 and 412:

392 power transmission Drives, Inco

- Page 413 and 414:

394 power transmission A spur gear,

- Page 415 and 416:

396 power transmission matic and hy

- Page 417 and 418:

398 power transmission trade. The c

- Page 419 and 420:

400 power transmission RMB Roulemen

- Page 421 and 422:

402 power transmission The company

- Page 423 and 424:

404 power transmission you’re bui

- Page 425 and 426:

406 professional societies Annual c

- Page 427 and 428:

408 Programming-examples Fawcette T

- Page 429 and 430:

410 Programming-languages Opensourc

- Page 431 and 432:

412 Programming-platforms & softwar

- Page 433 and 434:

414 Programming-robotic simulations

- Page 435 and 436:

416 Programming-telerobotics Autono

- Page 437 and 438:

418 :Radio Control Though not prima

- Page 439 and 440:

420 radio control Hobbico is a mast

- Page 441 and 442:

422 radio control RC Yellow Pages.

- Page 443 and 444:

424 radio control an airplane. Obvi

- Page 445 and 446:

426 Walther’s Model Railroad Mall

- Page 447 and 448:

428 radio control-accessories � (

- Page 449 and 450:

430 radio control-servo control Rev

- Page 451 and 452:

432 radio control-servo control Rol

- Page 453 and 454:

434 radio control-servos Hobby Hors

- Page 455 and 456:

436 retail �Retail The retail est

- Page 457 and 458:

438 �Retail-Armatures & Doll Part

- Page 459 and 460:

440 retail-armatures & doll parts S

- Page 461 and 462:

442 retail-arts & crafts � http:/

- Page 463 and 464:

444 retail-arts & crafts Hobby Lobb

- Page 465 and 466:

446 retail-arts & crafts � (800)

- Page 467 and 468:

448 retail-auctions • Toys & Hobb

- Page 469 and 470:

450 � info@govliquidation.com �

- Page 471 and 472:

452 up to determine which stuff is

- Page 473 and 474:

454 retail-discount & department Li

- Page 475 and 476:

456 retail-educational supply � l

- Page 477 and 478:

458 retail-general electronics Loca

- Page 479 and 480:

460 retail-general electronics AE A

- Page 481 and 482:

462 retail-general electronics A pr

- Page 483 and 484:

464 retail-general electronics Spec

- Page 485 and 486:

466 retail-general electronics Aust

- Page 487 and 488:

468 retail-general electronics �

- Page 489 and 490:

470 retail-general electronics Of c

- Page 491 and 492:

472 retail-general electronics MCM

- Page 493 and 494:

474 retail-general electronics �

- Page 495 and 496:

476 Tech America retail-general ele

- Page 497 and 498:

478 retail-hardware & home improvem

- Page 499 and 500:

480 retail-hardware & home improvem

- Page 501 and 502:

482 retail-office supplies Supplies

- Page 503 and 504:

484 retail-opticals and lasers Gene

- Page 505 and 506:

486 retail-other Darby Drug Co., In

- Page 507 and 508:

488 retail-other Nelson Appliance R

- Page 509 and 510:

490 video, and tools sections will

- Page 511 and 512:

492 retail-other materials Where to

- Page 513 and 514:

494 retail-robotics specialty • P

- Page 515 and 516:

496 retail-robotics specialty • S

- Page 517 and 518:

498 retail-robotics specialty Robot

- Page 519 and 520:

500 retail-robotics specialty � 1

- Page 521 and 522:

502 retail-science • Optics-Every

- Page 523 and 524:

504 retail-science • Tamiya Educa

- Page 525 and 526:

506 retail-science As you can imagi

- Page 527 and 528:

508 @ Retail-Surplus Electronics Su

- Page 529 and 530:

510 retail-surplus electronics BCD

- Page 531 and 532:

512 retail-surplus electronics �

- Page 533 and 534:

514 retail-surplus electronics tran

- Page 535 and 536:

516 retail-surplus mechanical New a

- Page 537 and 538:

518 retail-surplus mechanical Gatew

- Page 539 and 540:

520 servo motors and related hardwa

- Page 541 and 542:

522 retail-train & hobby � (800)

- Page 543 and 544:

524 retail-train & hobby Hobbylinc.

- Page 545 and 546:

526 t Robots You’ll find real, wo

- Page 547 and 548:

528 robots-beam � (403) 226-3741

- Page 549 and 550:

530 robots-experimental t Robots-Ex

- Page 551 and 552:

532 robots-hobby & kit � stevejon

- Page 553 and 554:

534 robots-hobby & kit Internationa

- Page 555 and 556:

536 robots-hobby & kit ple, the com

- Page 557 and 558:

538 robots-hobby & kit research rob

- Page 559 and 560:

540 robots-industrial/research �

- Page 561 and 562:

542 robots-industrial/research Kita

- Page 563 and 564:

544 robots-personal � http://www.

- Page 565 and 566:

546 sensors �Sensors A robot with

- Page 567 and 568:

548 sensors Crossbow Technology, In

- Page 569 and 570:

550 sensors Picard Indistries 20236

- Page 571 and 572:

552 sensors-encoders � (800) 235-

- Page 573 and 574:

554 sensors-encoders require softwa

- Page 575 and 576:

556 sensors-encoders � (973) 427-

- Page 577 and 578:

558 sensors-gps You can buy accesso

- Page 579 and 580:

560 sensors-gps � (408) 615-5100

- Page 581 and 582:

562 sensors-gps When the Swiss see

- Page 583 and 584:

564 sensors-optical Proximity Sensi

- Page 585 and 586:

566 sensors-optical Maker of optica

- Page 587 and 588:

568 sensors-other Making a Conducti

- Page 589 and 590:

570 sensors-other Sensing Touch wit

- Page 591 and 592:

572 sensors-other Fancy sensors for

- Page 593 and 594:

574 sensors-rfid Radio Frequency Id

- Page 595 and 596:

576 sensors-strain gauges & load ce

- Page 597 and 598:

578 sensors-tilt & accelerometer di

- Page 599 and 600:

580 sensors-tilt & accelerometer

- Page 601 and 602:

582 sensors-ultrasonic Ultrasonic D

- Page 603 and 604:

584 sensors-ultrasonic � (781) 74

- Page 605 and 606:

586 sensors-ultrasonic Robobix 2037

- Page 607 and 608:

588 ” Supplies-Casting & Mold Mak

- Page 609 and 610:

590 supplies-casting & mold making

- Page 611 and 612:

592 supplies-casting & mold making

- Page 613 and 614:

594 supplies-casting & mold making

- Page 615 and 616:

596 supplies-casting & mold making

- Page 617 and 618:

598 supplies-casting & mold making

- Page 619 and 620:

600 supplies-casting & mold making

- Page 621 and 622:

602 The listings in the section are

- Page 623 and 624:

604 supplies-glues & adhesives avai

- Page 625 and 626:

606 supplies-paints Manufacturers o

- Page 627 and 628:

608 test and measurement � (847)

- Page 629 and 630:

610 test and measurement Do You Nee

- Page 631 and 632:

612 test and measurement Logic Prob

- Page 633 and 634:

614 tools House of Tools 203829 #10

- Page 635 and 636:

616 tools • Go-Kart parts (such a

- Page 637 and 638:

618 tools � (800) 321-9260 � ht

- Page 639 and 640:

620 tools-cnc CNC Routers For the r

- Page 641 and 642:

622 tools-cnc CNC Retro-Fit Links.

- Page 643 and 644:

624 tools-cnc machine from computer

- Page 645 and 646:

626 tools-hand • Chesco-hex tools

- Page 647 and 648:

628 tools-hand Brookstone Company,

- Page 649 and 650:

630 tools-machinery � (570) 549-3

- Page 651 and 652:

632 tools-power Delta Machinery htt

- Page 653 and 654:

634 tools-precision & miniature Car

- Page 655 and 656:

636 tools-precision & miniature She

- Page 657 and 658:

638 toys Toys Some of the earliest

- Page 659 and 660:

640 toys Toys"R"Us 203887 461 From

- Page 661 and 662:

642 toys-construction EduBots 20242

- Page 663 and 664:

644 toys-construction Specialty rob

- Page 665 and 666:

646 toys-construction Model A Techn

- Page 667 and 668:

648 toys-construction Timberdoodle

- Page 669 and 670:

650 toys-robots � Obiwall@aol.com

- Page 671 and 672:

652 toys-robots Rocket USA 202075 7

- Page 673 and 674:

654 user groups Web page for Cybot

- Page 675 and 676:

656 user groups in electronics for

- Page 677 and 678:

658 user groups SRS has a major pre

- Page 679 and 680:

660 video �Video Low-cost video c

- Page 681 and 682:

662 video-cameras

- Page 683 and 684:

664 video-cameras Better Eyes to Se

- Page 685 and 686:

666 video-cameras Super Circuits We

- Page 687 and 688:

668 video-imagers Video Images: Ana

- Page 689 and 690:

670 video-programming & apis QCUIAG

- Page 691 and 692:

672 G Wheels and Casters If it roll

- Page 693 and 694:

674 wheels & casters � (800) 835-

- Page 695 and 696:

676 wheels & casters Du-Bro Product

- Page 697 and 698:

678 wheels & casters directional ca

- Page 699 and 700:

680 � (630) 858-9161 � (630) 85

- Page 701 and 702:

This page intentionally left blank.

- Page 703 and 704:

684 appendix a: Yellow Pages—Firs

- Page 705 and 706:

686 appendix a: Yellow Pages—Firs

- Page 707 and 708:

688 appendix a: Yellow Pages—Firs

- Page 709 and 710:

690 company reference Computers-Sin

- Page 711 and 712:

692 company reference Retail-Surplu

- Page 713 and 714:

694 company reference Tools-Accesso

- Page 715 and 716:

696 company reference Robots-Person

- Page 717 and 718:

698 company reference International

- Page 719 and 720:

700 company reference Microcontroll

- Page 721 and 722:

702 company reference Retail-Scienc

- Page 723 and 724:

704 company reference Sensors-Strai

- Page 725 and 726:

706 company reference Toys-Construc

- Page 727 and 728:

708 where to find it Retail-General

- Page 729 and 730:

710 where to find it Communications

- Page 731:

About the Author Gordon McComb is a