Fair warning

Fair warning

Fair warning

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

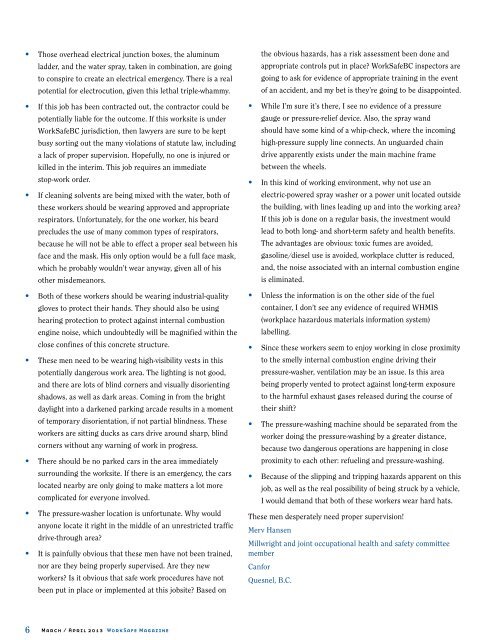

• Those overhead electrical junction boxes, the aluminum<br />

6<br />

ladder, and the water spray, taken in combination, are going<br />

to conspire to create an electrical emergency. There is a real<br />

potential for electrocution, given this lethal triple-whammy.<br />

• If this job has been contracted out, the contractor could be<br />

potentially liable for the outcome. If this worksite is under<br />

WorkSafeBC jurisdiction, then lawyers are sure to be kept<br />

busy sorting out the many violations of statute law, including<br />

a lack of proper supervision. Hopefully, no one is injured or<br />

killed in the interim. This job requires an immediate<br />

stop-work order.<br />

• If cleaning solvents are being mixed with the water, both of<br />

these workers should be wearing approved and appropriate<br />

respirators. Unfortunately, for the one worker, his beard<br />

precludes the use of many common types of respirators,<br />

because he will not be able to effect a proper seal between his<br />

face and the mask. His only option would be a full face mask,<br />

which he probably wouldn’t wear anyway, given all of his<br />

other misdemeanors.<br />

• Both of these workers should be wearing industrial-quality<br />

gloves to protect their hands. They should also be using<br />

hearing protection to protect against internal combustion<br />

engine noise, which undoubtedly will be magnified within the<br />

close confines of this concrete structure.<br />

• These men need to be wearing high-visibility vests in this<br />

potentially dangerous work area. The lighting is not good,<br />

and there are lots of blind corners and visually disorienting<br />

shadows, as well as dark areas. Coming in from the bright<br />

daylight into a darkened parking arcade results in a moment<br />

of temporary disorientation, if not partial blindness. These<br />

workers are sitting ducks as cars drive around sharp, blind<br />

corners without any <strong>warning</strong> of work in progress.<br />

• There should be no parked cars in the area immediately<br />

surrounding the worksite. If there is an emergency, the cars<br />

located nearby are only going to make matters a lot more<br />

complicated for everyone involved.<br />

• The pressure-washer location is unfortunate. Why would<br />

anyone locate it right in the middle of an unrestricted traffic<br />

drive-through area?<br />

• It is painfully obvious that these men have not been trained,<br />

nor are they being properly supervised. Are they new<br />

workers? Is it obvious that safe work procedures have not<br />

been put in place or implemented at this jobsite? Based on<br />

March / April 2013 WorkSafe Magazine<br />

the obvious hazards, has a risk assessment been done and<br />

appropriate controls put in place? WorkSafeBC inspectors are<br />

going to ask for evidence of appropriate training in the event<br />

of an accident, and my bet is they’re going to be disappointed.<br />

• While I’m sure it’s there, I see no evidence of a pressure<br />

gauge or pressure-relief device. Also, the spray wand<br />

should have some kind of a whip-check, where the incoming<br />

high-pressure supply line connects. An unguarded chain<br />

drive apparently exists under the main machine frame<br />

between the wheels.<br />

• In this kind of working environment, why not use an<br />

electric-powered spray washer or a power unit located outside<br />

the building, with lines leading up and into the working area?<br />

If this job is done on a regular basis, the investment would<br />

lead to both long- and short-term safety and health benefits.<br />

The advantages are obvious: toxic fumes are avoided,<br />

gasoline/diesel use is avoided, workplace clutter is reduced,<br />

and, the noise associated with an internal combustion engine<br />

is eliminated.<br />

• Unless the information is on the other side of the fuel<br />

container, I don’t see any evidence of required WHMIS<br />

(workplace hazardous materials information system)<br />

labelling.<br />

• Since these workers seem to enjoy working in close proximity<br />

to the smelly internal combustion engine driving their<br />

pressure-washer, ventilation may be an issue. Is this area<br />

being properly vented to protect against long-term exposure<br />

to the harmful exhaust gases released during the course of<br />

their shift?<br />

• The pressure-washing machine should be separated from the<br />

worker doing the pressure-washing by a greater distance,<br />

because two dangerous operations are happening in close<br />

proximity to each other: refueling and pressure-washing.<br />

• Because of the slipping and tripping hazards apparent on this<br />

job, as well as the real possibility of being struck by a vehicle,<br />

I would demand that both of these workers wear hard hats.<br />

These men desperately need proper supervision!<br />

Merv Hansen<br />

Millwright and joint occupational health and safety committee<br />

member<br />

Canfor<br />

Quesnel, B.C.