TAFE wet area text.pdf - Mike's Trade Wiki

TAFE wet area text.pdf - Mike's Trade Wiki

TAFE wet area text.pdf - Mike's Trade Wiki

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

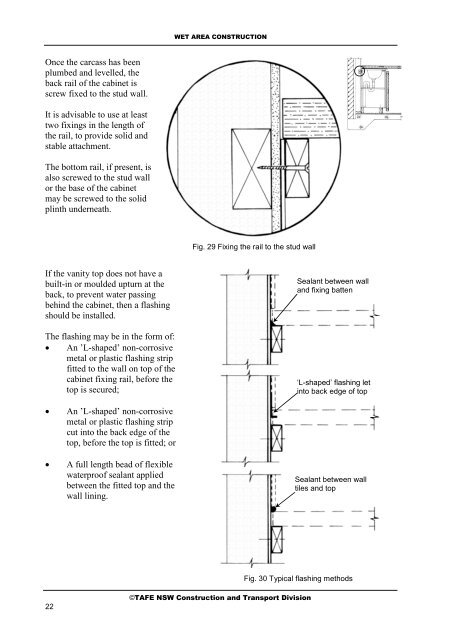

Once the carcass has been<br />

plumbed and levelled, the<br />

back rail of the cabinet is<br />

screw fixed to the stud wall.<br />

It is advisable to use at least<br />

two fixings in the length of<br />

the rail, to provide solid and<br />

stable attachment.<br />

The bottom rail, if present, is<br />

also screwed to the stud wall<br />

or the base of the cabinet<br />

may be screwed to the solid<br />

plinth underneath.<br />

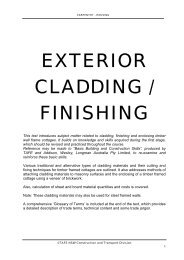

If the vanity top does not have a<br />

built-in or moulded upturn at the<br />

back, to prevent water passing<br />

behind the cabinet, then a flashing<br />

should be installed.<br />

The flashing may be in the form of:<br />

� An ’L-shaped’ non-corrosive<br />

metal or plastic flashing strip<br />

fitted to the wall on top of the<br />

cabinet fixing rail, before the<br />

top is secured;<br />

� An ’L-shaped’ non-corrosive<br />

metal or plastic flashing strip<br />

cut into the back edge of the<br />

top, before the top is fitted; or<br />

� A full length bead of flexible<br />

waterproof sealant applied<br />

between the fitted top and the<br />

wall lining.<br />

22<br />

WET AREA CONSTRUCTION<br />

Fig. 29 Fixing the rail to the stud wall<br />

Fig. 30 Typical flashing methods<br />

©<strong>TAFE</strong> NSW Construction and Transport Division<br />

Sealant between wall<br />

and fixing batten<br />

‘L-shaped’ flashing let<br />

into back edge of top<br />

Sealant between wall<br />

tiles and top