Setting new standards for smooth surfaces: - Bosch

Setting new standards for smooth surfaces: - Bosch

Setting new standards for smooth surfaces: - Bosch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

16 I Sanding and Polishing<br />

Abrasive components<br />

<strong>for</strong> perfect <strong>surfaces</strong>: Structure.<br />

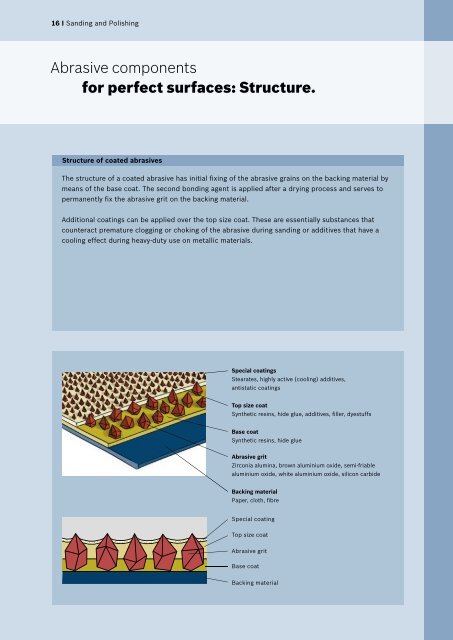

Structure of coated abrasives<br />

The structure of a coated abrasive has initial fi xing of the abrasive grains on the backing material by<br />

means of the base coat. The second bonding agent is applied after a drying process and serves to<br />

permanently fi x the abrasive grit on the backing material.<br />

Additional coatings can be applied over the top size coat. These are essentially substances that<br />

counteract premature clogging or choking of the abrasive during sanding or additives that have a<br />

cooling effect during heavy-duty use on metallic materials.<br />

Special coatings<br />

Stearates, highly active (cooling) additives,<br />

antistatic coatings<br />

Top size coat<br />

Synthetic resins, hide glue, additives, fi ller, dyestuffs<br />

Base coat<br />

Synthetic resins, hide glue<br />

Abrasive grit<br />

Zirconia alumina, brown aluminium oxide, semi-friable<br />

aluminium oxide, white aluminium oxide, silicon carbide<br />

Backing material<br />

Paper, cloth, fi bre<br />

Special coating<br />

Top size coat<br />

Abrasive grit<br />

Base coat<br />

Backing material