Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNICAL TORQUE<br />

Project 605 Ute<br />

– Part 3<br />

Following in the footspteps of the Aussies who<br />

created the 203 Aussie ute from 203 panel vans<br />

Richard Marken in Brisbane is creating a ute from<br />

a 605 sedan. Here is part three from the August<br />

issue of Peugeotmania.<br />

<strong>THE</strong>RE is one job when doing body work that you should really<br />

try to avoid, that is welding up roof panels. They twist and<br />

warp so easily that you have to take a very slow approach to<br />

welding.<br />

Me! I made three mistakes when I fitted the rear roof section<br />

and C pillars.<br />

The first mistake was that I stood the roof section up at the<br />

back of the 605 whist I stuffed around with the spigot tubes<br />

that I was using to locate and strengthen the frame support.<br />

This made it quite easy for me to then knock the rear roof<br />

section over, resulting in a nice crease in the middle of the<br />

roof section. This didn’t unduly upset me as I was going to cut<br />

the roof section into two pieces so that the C pillars lined up<br />

properly with the B pillars and thus maintained the side profile<br />

of the car.<br />

The second mistake was to once again stand the roof section up<br />

against the back of the 605 and begin stuffing around with the<br />

spigot tubes again, yes! I knocked the bloody thing over again,<br />

resulting in more creases along the rear edge, but once again I<br />

22 TORQUE 909<br />

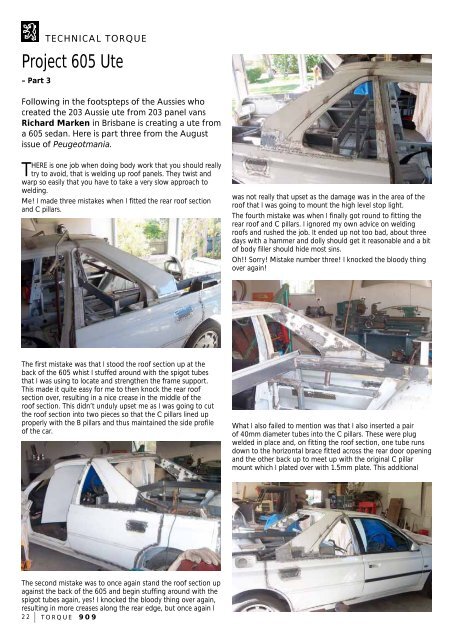

The photo shows door opening braced before metal is cut.<br />

was not really that upset as the damage was in the area of the<br />

roof that I was going to mount the high level stop light.<br />

The fourth mistake was when I finally got round to fitting the<br />

rear roof and C pillars. I ignored my own advice on welding<br />

roofs and rushed the job. It ended up not too bad, about three<br />

days with a hammer and dolly should get it reasonable and a bit<br />

of body filler should hide most sins.<br />

Oh!! Sorry! Mistake number three! I knocked the bloody thing<br />

over again!<br />

What I also failed to mention was that I also inserted a pair<br />

of 40mm diameter tubes into the C pillars. These were plug<br />

welded in place and, on fitting the roof section, one tube runs<br />

down to the horizontal brace fitted across the rear door opening<br />

and the other back up to meet up with the original C pillar<br />

mount which I plated over with 1.5mm plate. This additional