spectrum

spectrum

spectrum

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Deep drawing presses<br />

18 <strong>spectrum</strong> METAL FORMING 2012<br />

p S. Dunkes GmbH, Germany<br />

Optimally Tested<br />

S. Dunkes has developed a frame deep drawing press that<br />

can be used in the auto parts industry to comprehensively<br />

try yout tools for subsequent q usability. y<br />

The variety of models produced by the automotive<br />

industry is continually increasing,<br />

while production cycles become shorter and<br />

shorter. In order to keep pace, new tools must constantly<br />

be developed. For more than 50 years,<br />

S. Dunkes GmbH from Kirchheim unter Teck in Germany,<br />

has been making machines and systems associated<br />

with forming and connection technology.<br />

The company has now made a hydraulic tryout<br />

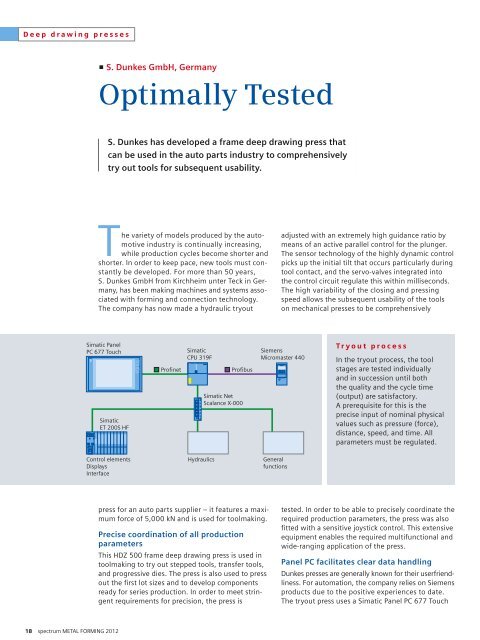

Simatic Panel<br />

PC 677 Touch<br />

Simatic<br />

ET 200S HF<br />

Control elements<br />

Displays<br />

Interface<br />

Simatic<br />

CPU 319F<br />

Profinet Profibus<br />

Hydraulics<br />

Simatic Net<br />

Scalance X-000<br />

press for an auto parts supplier – it features a maximum<br />

force of 5,000 kN and is used for toolmaking.<br />

Precise coordination of all production<br />

parameters<br />

This HDZ 500 frame deep drawing press is used in<br />

toolmaking to try out stepped tools, transfer tools,<br />

and progressive dies. The press is also used to press<br />

out the fi rst lot sizes and to develop components<br />

ready for series production. In order to meet stringent<br />

requirements for precision, the press is<br />

General<br />

functions<br />

adjusted with an extremely high guidance ratio by<br />

means of an active parallel control for the plunger.<br />

The sensor technology of the highly dynamic control<br />

picks up the initial tilt that occurs particularly during<br />

tool contact, and the servo-valves integrated into<br />

the control circuit regulate this within milliseconds.<br />

The high variability of the closing and pressing<br />

speed allows the subsequent usability of the tools<br />

on mechanical presses to be comprehensively<br />

Siemens<br />

Micromaster 440<br />

Tryout process<br />

In the tryout process, the tool<br />

stages are tested individually<br />

and in succession until both<br />

the quality and the cycle time<br />

(output) are satisfactory.<br />

A prerequisite for this is the<br />

precise input of nominal physical<br />

values such as pressure (force),<br />

distance, speed, and time. All<br />

parameters must be regulated.<br />

tested. In order to be able to precisely coordinate the<br />

required production parameters, the press was also<br />

fi tted with a sensitive joystick control. This extensive<br />

equipment enables the required multifunctional and<br />

wide-ranging application of the press.<br />

Panel PC facilitates clear data handling<br />

Dunkes presses are generally known for their userfriendliness.<br />

For automation, the company relies on Siemens<br />

products due to the positive experiences to date.<br />

The tryout press uses a Simatic Panel PC 677 Touch