Metal-cutting tools Catalogue

Metal-cutting tools Catalogue

Metal-cutting tools Catalogue

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4<br />

Information about Microbor CBN<br />

www.microbor.com <strong>Metal</strong>-<strong>cutting</strong> <strong>tools</strong><br />

What is CBN based composite?<br />

The CBN grain size and grain percentage strongly influence composite operating properties, as well<br />

as binding material properties.<br />

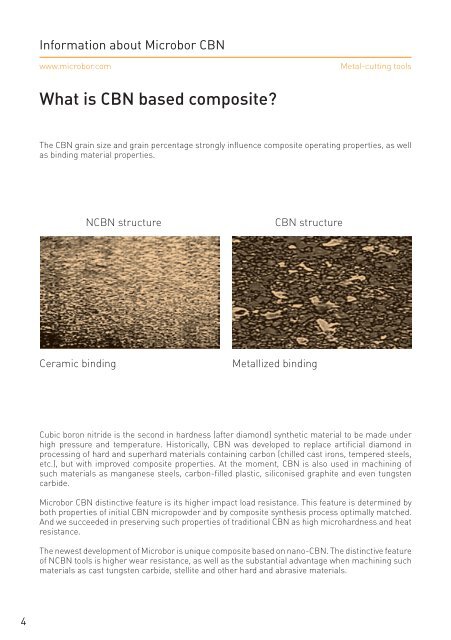

NCBN structure CBN structure<br />

Ceramic binding <strong>Metal</strong>lized binding<br />

Cubic boron nitride is the second in hardness (after diamond) synthetic material to be made under<br />

high pressure and temperature. Historically, CBN was developed to replace artificial diamond in<br />

processing of hard and superhard materials containing carbon (chilled cast irons, tempered steels,<br />

etc.), but with improved composite properties. At the moment, CBN is also used in machining of<br />

such materials as manganese steels, carbon-filled plastic, siliconised graphite and even tungsten<br />

carbide.<br />

Microbor CBN distinctive feature is its higher impact load resistance. This feature is determined by<br />

both properties of initial CBN micropowder and by composite synthesis process optimally matched.<br />

And we succeeded in preserving such properties of traditional CBN as high microhardness and heat<br />

resistance.<br />

The newest development of Microbor is unique composite based on nano-CBN. The distinctive feature<br />

of NCBN <strong>tools</strong> is higher wear resistance, as well as the substantial advantage when machining such<br />

materials as cast tungsten carbide, stellite and other hard and abrasive materials.