SPEEDSKIM-INTRODUCTION-USERGUIDE-NEWS-MARCH-2013

SPEEDSKIM-INTRODUCTION-USERGUIDE-NEWS-MARCH-2013

SPEEDSKIM-INTRODUCTION-USERGUIDE-NEWS-MARCH-2013

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

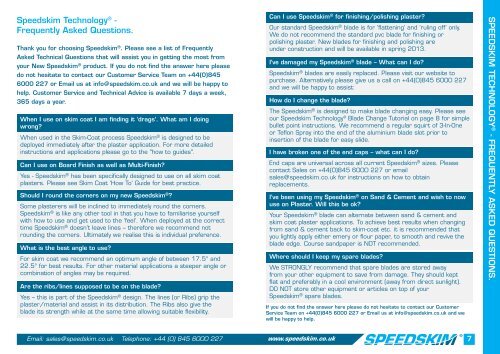

Speedskim Technology ® -<br />

Frequently Asked Questions.<br />

Thank you for choosing Speedskim ® . Please see a list of Frequently<br />

Asked Technical Questions that will assist you in getting the most from<br />

your New Speedskim ® product. If you do not find the answer here please<br />

do not hesitate to contact our Customer Service Team on +44(0)845<br />

6000 227 or Email us at info@speedskim.co.uk and we will be happy to<br />

help. Customer Service and Technical Advice is available 7 days a week,<br />

365 days a year.<br />

When I use on skim coat I am finding it ‘drags’. What am I doing<br />

wrong?<br />

When used in the Skim-Coat process Speedskim ® is designed to be<br />

deployed immediately after the plaster application. For more detailed<br />

instructions and applications please go to the "how to guides".<br />

Can I use on Board Finish as well as Multi-Finish?<br />

Yes - Speedskim ® has been specifically designed to use on all skim coat<br />

plasters. Please see Skim Coat ‘How To’ Guide for best practice.<br />

Should I round the corners on my new Speedskim ® ?<br />

Some plasterers will be inclined to immediately round the corners.<br />

Speedskim ® is like any other tool in that you have to familiarise yourself<br />

with how to use and get used to the ‘feel’. When deployed at the correct<br />

time Speedskim ® doesn’t leave lines – therefore we recommend not<br />

rounding the corners. Ultimately we realise this is individual preference.<br />

What is the best angle to use?<br />

For skim coat we recommend an optimum angle of between 17.5° and<br />

22.5° for best results. For other material applications a steeper angle or<br />

combination of angles may be required.<br />

Are the ribs/lines supposed to be on the blade?<br />

Yes – this is part of the Speedskim ® design. The lines (or Ribs) grip the<br />

plaster/material and assist in its distribution. The Ribs also give the<br />

blade its strength while at the same time allowing suitable flexibility.<br />

Email: sales@speedskim.co.uk Telephone: +44 (0) 845 6000 227<br />

Can I use Speedskim ® for finishing/polishing plaster?<br />

Our standard Speedskim ® blade is for ‘flattening’ and ‘ruling off’ only.<br />

We do not recommend the standard pvc blade for finishing or<br />

polishing plaster. New blades for finishing and polishing are<br />

under construction and will be available in spring <strong>2013</strong>.<br />

I’ve damaged my Speedskim ® blade – What can I do?<br />

Speedskim ® blades are easily replaced. Please visit our website to<br />

purchase. Alternatively please give us a call on +44(0)845 6000 227<br />

and we will be happy to assist:<br />

How do I change the blade?<br />

The Speedskim ® is designed to make blade changing easy. Please see<br />

our Speedskim Technology ® Blade Change Tutorial on page 8 for simple<br />

bullet point instructions. We recommend a regular squirt of 3-In-One<br />

or Teflon Spray into the end of the aluminium blade slot prior to<br />

insertion of the blade for easy slide.<br />

I have broken one of the end caps – what can I do?<br />

End caps are universal across all current Speedskim ® sizes. Please<br />

contact Sales on +44(0)845 6000 227 or email<br />

sales@speedskim.co.uk for instructions on how to obtain<br />

replacements.<br />

I’ve been using my Speedskim ® on Sand & Cement and wish to now<br />

use on Plaster. Will this be ok?<br />

Your Speedskim ® blade can alternate between sand & cement and<br />

skim coat plaster applications. To achieve best results when changing<br />

from sand & cement back to skim-coat etc. it is recommended that<br />

you lightly apply either emery or flour paper, to smooth and revive the<br />

blade edge. Course sandpaper is NOT recommended.<br />

Where should I keep my spare blades?<br />

We STRONGLY recommend that spare blades are stored away<br />

from your other equipment to save from damage. They should kept<br />

flat and preferably in a cool environment (away from direct sunlight).<br />

DO NOT store other equipment or articles on top of your<br />

Speedskim ® spare blades.<br />

If you do not find the answer here please do not hesitate to contact our Customer<br />

Service Team on +44(0)845 6000 227 or Email us at info@speedskim.co.uk and we<br />

will be happy to help.<br />

www.speedskim.co.uk<br />

7<br />

<strong>SPEEDSKIM</strong> TECHNOLOGY ® - FREQUENTLY ASKED QUESTIONS.