who guideline on quality risk management - World Health ...

who guideline on quality risk management - World Health ...

who guideline on quality risk management - World Health ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Working document QAS/10.376<br />

page 20<br />

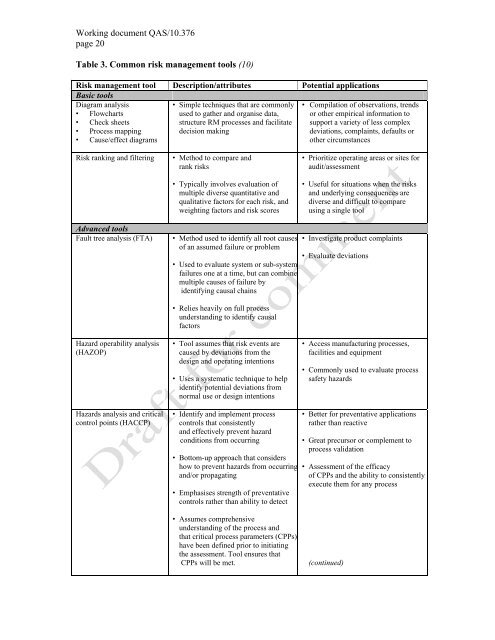

Table 3. Comm<strong>on</strong> <strong>risk</strong> <strong>management</strong> tools (10)<br />

Risk <strong>management</strong> tool Descripti<strong>on</strong>/attributes Potential applicati<strong>on</strong>s<br />

Basic tools<br />

Diagram analysis<br />

• Flowcharts<br />

• Check sheets<br />

• Process mapping<br />

• Cause/effect diagrams<br />

• Simple techniques that are comm<strong>on</strong>ly<br />

used to gather and organise data,<br />

structure RM processes and facilitate<br />

decisi<strong>on</strong> making<br />

Risk ranking and filtering • Method to compare and<br />

rank <strong>risk</strong>s<br />

• Typically involves evaluati<strong>on</strong> of<br />

multiple diverse quantitative and<br />

qualitative factors for each <strong>risk</strong>, and<br />

weighting factors and <strong>risk</strong> scores<br />

Advanced tools<br />

Fault tree analysis (FTA) • Method used to identify all root causes<br />

of an assumed failure or problem<br />

Hazard operability analysis<br />

(HAZOP)<br />

Hazards analysis and critical<br />

c<strong>on</strong>trol points (HACCP)<br />

• Used to evaluate system or sub-system<br />

failures <strong>on</strong>e at a time, but can combine<br />

multiple causes of failure by<br />

identifying causal chains<br />

• Relies heavily <strong>on</strong> full process<br />

understanding to identify causal<br />

factors<br />

• Tool assumes that <strong>risk</strong> events are<br />

caused by deviati<strong>on</strong>s from the<br />

design and operating intenti<strong>on</strong>s<br />

• Uses a systematic technique to help<br />

identify potential deviati<strong>on</strong>s from<br />

normal use or design intenti<strong>on</strong>s<br />

• Identify and implement process<br />

c<strong>on</strong>trols that c<strong>on</strong>sistently<br />

and effectively prevent hazard<br />

c<strong>on</strong>diti<strong>on</strong>s from occurring<br />

• Bottom-up approach that c<strong>on</strong>siders<br />

how to prevent hazards from occurring<br />

and/or propagating<br />

• Emphasises strength of preventative<br />

c<strong>on</strong>trols rather than ability to detect<br />

• Assumes comprehensive<br />

understanding of the process and<br />

that critical process parameters (CPPs)<br />

have been defined prior to initiating<br />

the assessment. Tool ensures that<br />

CPPs will be met.<br />

• Compilati<strong>on</strong> of observati<strong>on</strong>s, trends<br />

or other empirical informati<strong>on</strong> to<br />

support a variety of less complex<br />

deviati<strong>on</strong>s, complaints, defaults or<br />

other circumstances<br />

• Prioritize operating areas or sites for<br />

audit/assessment<br />

• Useful for situati<strong>on</strong>s when the <strong>risk</strong>s<br />

and underlying c<strong>on</strong>sequences are<br />

diverse and difficult to compare<br />

using a single tool<br />

• Investigate product complaints<br />

• Evaluate deviati<strong>on</strong>s<br />

• Access manufacturing processes,<br />

facilities and equipment<br />

• Comm<strong>on</strong>ly used to evaluate process<br />

safety hazards<br />

• Better for preventative applicati<strong>on</strong>s<br />

rather than reactive<br />

• Great precursor or complement to<br />

process validati<strong>on</strong><br />

• Assessment of the efficacy<br />

of CPPs and the ability to c<strong>on</strong>sistently<br />

execute them for any process<br />

(c<strong>on</strong>tinued)