Gusmer Wine Products Catalog - Gusmer Enterprises, Inc.

Gusmer Wine Products Catalog - Gusmer Enterprises, Inc.

Gusmer Wine Products Catalog - Gusmer Enterprises, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Filtration<br />

Application Notes for<br />

Sheet Filter Presses<br />

Operation<br />

Typically, a filter press consists of a series of plates<br />

equipped with inlet and outlet ports. Depending on the<br />

type of press, the ports may be internally or externally<br />

ported. When the press is closed and tightened through<br />

manual or hydraulic means, the plates, gasketed ports,<br />

and sheets are closed to form a tight seal for feed and<br />

filtrate passage. The unfiltered product passes through<br />

the inlet ports of the plate to the depth filter sheet. The<br />

depth filter sheet separates the undesired contaminant<br />

and allows the cleaned product to flow to the outlet<br />

plate. The outlet plate distributes the cleaned product to<br />

the discharge or outlet port.<br />

Advantages of Filter Presses<br />

• Very versatile—full range of wine filtration applications<br />

• Large filter area with additional surface area available<br />

with more plates<br />

• Flexible, modular design with ability to conduct two<br />

stage filtrations<br />

• Good process scalability from bench to production<br />

scale<br />

• Consistent and reliable filtration results<br />

• Low maintenance costs<br />

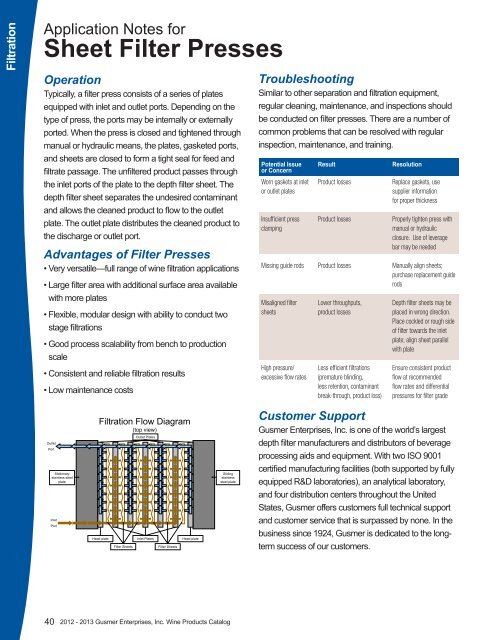

Outlet<br />

Port<br />

Stationary<br />

stainless steel<br />

plate<br />

Inlet<br />

Port<br />

Filtration Flow Diagram<br />

(top view)<br />

Outlet Plates<br />

Head plate Inlet Plates<br />

Head plate<br />

Filter Sheets Filter Sheets<br />

Sliding<br />

stainless<br />

steel plate<br />

40 2012 - 2013 <strong>Gusmer</strong> <strong>Enterprises</strong>, <strong>Inc</strong>. <strong>Wine</strong> <strong>Products</strong> <strong>Catalog</strong><br />

Troubleshooting<br />

Similar to other separation and filtration equipment,<br />

regular cleaning, maintenance, and inspections should<br />

be conducted on filter presses. There are a number of<br />

common problems that can be resolved with regular<br />

inspection, maintenance, and training.<br />

Potential Issue<br />

or Concern<br />

result resolution<br />

Worn gaskets at inlet Product losses Replace gaskets, use<br />

or outlet plates supplier information<br />

for proper thickness<br />

Insufficient press Product losses Properly tighten press with<br />

clamping manual or hydraulic<br />

closure. Use of leverage<br />

bar may be needed<br />

Missing guide rods Product losses Manually align sheets;<br />

purchase replacement guide<br />

rods<br />

Misaligned filter Lower throughputs, Depth filter sheets may be<br />

sheets product losses placed in wrong direction.<br />

Place cockled or rough side<br />

of filter towards the inlet<br />

plate; align sheet parallel<br />

with plate<br />

High pressure/ Less efficient filtrations Ensure consistent product<br />

excessive flow rates (premature blinding, flow at recommended<br />

less retention, contaminant flow rates and differential<br />

break-through, product loss) pressures for filter grade<br />

Customer Support<br />

<strong>Gusmer</strong> <strong>Enterprises</strong>, <strong>Inc</strong>. is one of the world’s largest<br />

depth filter manufacturers and distributors of beverage<br />

processing aids and equipment. With two ISO 9001<br />

certified manufacturing facilities (both supported by fully<br />

equipped R&D laboratories), an analytical laboratory,<br />

and four distribution centers throughout the United<br />

States, <strong>Gusmer</strong> offers customers full technical support<br />

and customer service that is surpassed by none. In the<br />

business since 1924, <strong>Gusmer</strong> is dedicated to the longterm<br />

success of our customers.