PRESSURE GAUGE PRESSURE GAUGE

PRESSURE GAUGE PRESSURE GAUGE

PRESSURE GAUGE PRESSURE GAUGE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PRESSURE</strong><br />

<strong>GAUGE</strong><br />

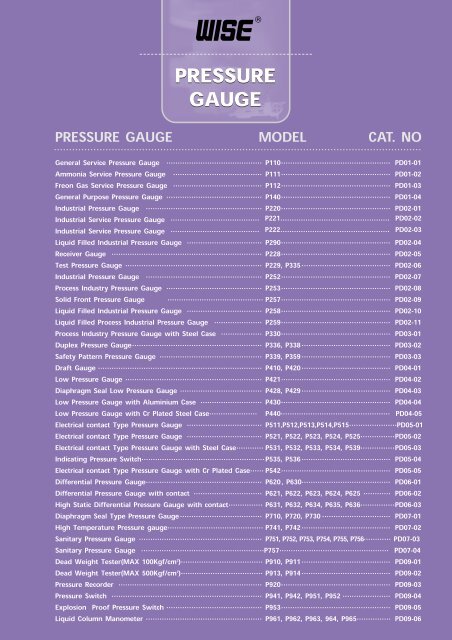

<strong>PRESSURE</strong> <strong>GAUGE</strong> MODEL CAT. NO<br />

General Service Pressure Gauge …………………………………… P110………………………………………… PD01-01<br />

Ammonia Service Pressure Gauge ………………………………… P111………………………………………… PD01-02<br />

Freon Gas Service Pressure Gauge ………………………………… P112………………………………………… PD01-03<br />

General Purpose Pressure Gauge …………………………………… P140………………………………………… PD01-04<br />

Industrial Pressure Gauge …………………………………………… P220………………………………………… PD02-01<br />

Industrial Service Pressure Gauge ………………………………… P221………………………………………… PD02-02<br />

Industrial Service Pressure Gauge ………………………………… P222………………………………………… PD02-03<br />

Liquid Filled Industrial Pressure Gauge …………………………… P290………………………………………… PD02-04<br />

Receiver Gauge ………………………………………………………… P228………………………………………… PD02-05<br />

Test Pressure Gauge …………………………………………………… P229, P335………………………………… PD02-06<br />

Industrial Pressure Gauge …………………………………………… P252………………………………………… PD02-07<br />

Process Industry Pressure Gauge …………………………………… P253………………………………………… PD02-08<br />

Solid Front Pressure Gauge ……………………………………P257………………………………………… PD02-09<br />

Liquid Filled Industrial Pressure Gauge …………………………… P258………………………………………… PD02-10<br />

Liquid Filled Process Industrial Pressure Gauge ………………… P259………………………………………… PD02-11<br />

Process Industry Pressure Gauge with Steel Case ……………… P330………………………………………… PD03-01<br />

Duplex Pressure Gauge………………………………………………… P336, P338………………………………… PD03-02<br />

Safety Pattern Pressure Gauge ……………………………………… P339, P359………………………………… PD03-03<br />

Draft Gauge……………………………………………………………… P410, P420………………………………… PD04-01<br />

Low Pressure Gauge …………………………………………………… P421………………………………………… PD04-02<br />

Diaphragm Seal Low Pressure Gauge ……………………………… P428, P429………………………………… PD04-03<br />

Low Pressure Gauge with Aluminium Case ……………………… P430………………………………………… PD04-04<br />

Low Pressure Gauge with Cr Plated Steel Case………………… P440………………………………………… PD04-05<br />

Electrical contact Type Pressure Gauge …………………………… P511,P512,P513,P514,P515…………………PD05-01<br />

Electrical contact Type Pressure Gauge …………………………… P521, P522, P523, P524, P525……………PD05-02<br />

Electrical contact Type Pressure Gauge with Steel Case…………P531, P532, P533, P534, P539……………PD05-03<br />

Indicating Pressure Switch………………………………………………P535, P536………………………………… PD05-04<br />

Electrical contact Type Pressure Gauge with Cr Plated Case……P542………………………………………… PD05-05<br />

Differential Pressure Gauge…………………………………………… P620, P630………………………………… PD06-01<br />

Differential Pressure Gauge with contact ………………………… P621, P622, P623, P624, P625 ………… PD06-02<br />

High Static Differential Pressure Gauge with contact…………… P631, P632, P634, P635, P636……………PD06-03<br />

Diaphragm Seal Type Pressure Gauge……………………………… P710, P720, P730………………………… PD07-01<br />

High Temperature Pressure gauge……………………………………P741, P742………………………………… PD07-02<br />

Sanitary Pressure Gauge ……………………………………………… P751, P752, P753, P754, P755, P756………… PD07-03<br />

Sanitary Pressure Gauge ………………………………………………P757………………………………………… PD07-04<br />

Dead Weight Tester(MAX 100Kgf/cm2)……………………………… P910, P911………………………………… PD09-01<br />

Dead Weight Tester(MAX 500Kgf/cm2)……………………………… P913, P914………………………………… PD09-02<br />

Pressure Recorder ……………………………………………………… P920………………………………………… PD09-03<br />

Pressure Switch ………………………………………………………… P941, P942, P951, P952………………… PD09-04<br />

Explosion Proof Pressure Switch…………………………………… P953………………………………………… PD09-05<br />

Liquid Column Manometer …………………………………………… P961, P962, P963, 964, P965…………… PD09-06

<strong>PRESSURE</strong> MEASUREMENT<br />

There are four types of pressure measurements:<br />

Measurement of absolute pressure : measurements are made with respect to absolute pressure, for<br />

example as with atmospheric pressure.<br />

Measurement of relative or effective pressure : measurements are made with respect to ambient pressure.<br />

generally atmospheric pressure.<br />

Measurement of differential pressure : this is the difference between two pressures.<br />

One<br />

Measurement<br />

can also<br />

of vacuum<br />

distinguish<br />

pressure :<br />

pressure<br />

this is referred<br />

measurements<br />

to ambient pressure, usually<br />

according<br />

atmospheric<br />

to<br />

pressure.<br />

their<br />

behavior with time :<br />

Static or quasi-static pressure, which varies only slowly with time. Examples are atmospheric pressure,<br />

level measurements and certain pressures in industrial processes such as in the petrochemical, food and pulp<br />

and paper industries.<br />

Fluctuating pressure, which can be random or cyclic. Examples are the pressure inside a gun barrel, in a<br />

plastic injection mould, in an internal combustion engine cylinder, etc.<br />

Line (Static pressure pressure)<br />

Atmospheric (Fluctuating reference) pressure<br />

Absolute<br />

(Theoretical<br />

vacuum<br />

limit)<br />

<strong>PRESSURE</strong> <strong>GAUGE</strong>S<br />

Absolute<br />

pressure<br />

Relative pressure<br />

Vacuum pressure<br />

Mechanical apparatus indicating the value of the local pressure<br />

Differential pressure<br />

1.<br />

2.Window<br />

Bezelring<br />

3.Window<br />

4.Dial<br />

gasket<br />

5.Movement<br />

6.Tube<br />

7.Case<br />

8.Blow<br />

9.Connection<br />

out disc<br />

10.Connection<br />

11.Pointer<br />

gasket<br />

<strong>PRESSURE</strong>

<strong>PRESSURE</strong><br />

PRINCIPLE OF OPERATION :<br />

The tube is displaced in proportion to<br />

the applied pressure, which causes the<br />

pointer to move by means of a<br />

mechanically amplifying linkage.<br />

Components of a metallic pressure gauge :<br />

BOURDON tube or tube :<br />

The sensing element consists of a metallic tube of various<br />

cross-sections shaped in the form of a . One end is<br />

fixed and connected to the pressure circuit and the other<br />

is sealed and free to move. When pressure is applied to<br />

the tube the free end is forced outwards.<br />

(Measuring range from around 400 mbar to 60 bar).<br />

Capsules :<br />

The sensing element consists of two thin<br />

corrugated sections laser welded together. The<br />

capsule thus formed acts as a cavity that slightly<br />

deforms with variations in pressure. It is suitable<br />

for measuring very low pressures. (Measuring<br />

range from 0 to about 600 mbar).<br />

Bellows :<br />

The sensing element consists<br />

of two flanges connected to a<br />

flexible cylinder.<br />

Pressure applied to the interior<br />

of the chamber causes it to<br />

deform by an amount<br />

proportional to the pressure.<br />

They are mainly used in<br />

differential pressure gauges<br />

and pressure switches.<br />

Helicoil, tubes<br />

(or pig tails) :<br />

The coil is cylindrical.<br />

It has the same<br />

characteristics as a spiral<br />

tube but with greater<br />

resistance to fatigue due<br />

to better stress distribution.<br />

(Measuring range from<br />

about 60 to 3000 bar).<br />

Spiral tubes :<br />

These use the same<br />

principle as the tube<br />

but with the deflection of<br />

the free end of the tube<br />

amplified due to the spiral<br />

shape.<br />

They are mainly used in<br />

gas expansion thermometers.<br />

Position of tube at P=0<br />

Position of tube at Pmeasured

MOUNTING<br />

Cases<br />

Different types of cases are possible according to position of the connection.<br />

TYPE B TYPE N TYPE D TYPE A TYPE K TYPE G TYPE M<br />

Back flange<br />

Bottom<br />

connection<br />

Position<br />

YES<br />

Front flange<br />

Back<br />

connection<br />

Front flange<br />

Bottom<br />

connection<br />

Flangeless<br />

Bottom<br />

connection<br />

Back flange<br />

Back<br />

connection<br />

Flangeless<br />

Back<br />

connection<br />

Always vertical, otherwise specify the direction and angle.<br />

A pressure gauge is calibrated in a vertical position, however and this is not a defect, the pointer may be out of<br />

zero if the instrument is horizontal, chiefly for low pressure ranges.<br />

Threads<br />

Standard threads are : parallel BSP (gas) or conical NPT (briggs).<br />

1. Parallel thread BSP (gas).<br />

Place a gasket between the end of the thread and around the<br />

spigot.<br />

2. Conical thread NPT (briggs)<br />

Tightness is achieved metal on metal without any gasket. However<br />

a teflon tape wound around the thread provides a better tightness<br />

and makes the screwing easier.<br />

BOURDON tube<br />

The BOURDON tube can be made of bronze, st. steel, MONEL,<br />

nickel-silver alloy, etc...<br />

Sometimes for low or differential pressures, the tube is replaced by<br />

a capsule or by 2 bellows.<br />

Oxygen<br />

WARNING :<br />

For oxygen service, oil-free manometric parts is imperative.<br />

Specify when ordering.<br />

YES<br />

Gasket<br />

BSP<br />

threading<br />

NO<br />

Front<br />

Strap<br />

flange<br />

fixing<br />

connection Back<br />

NO<br />

NPT<br />

threading<br />

<strong>PRESSURE</strong>

<strong>PRESSURE</strong><br />

Installation<br />

Never install the pressure gauge by turning the case but mount it<br />

with a wrench by means of the hexagon or flats provided on the<br />

socket.<br />

Isolating cocks<br />

A pressure gauge must never be mounted an isolating cock.<br />

Vibrations<br />

Vibrations of the pressure gauge must be avoided to prevent excessive<br />

wear of the mechanism.<br />

It would be better to set the gauge on a rigid support on which the<br />

vibrations of the pipe have no influence (consult our chemical seals/<br />

accessories manual).<br />

A flexible small diameter capillary can also be<br />

placed between the gauge and diaphragm seal.<br />

A capillary can also occasionally be used as a<br />

vibrations or pulsations dampener.<br />

Pressure pulsations<br />

In the case of pressure measurements of<br />

pulsating fluids a dampener should be fitted<br />

between the pressure gauge and the pipe.<br />

Adjustment of dampener will be done on line,<br />

where the gauge is used, according to the pressure<br />

pulsations.<br />

Corrosion<br />

If stainless steel or MONEL do not provide sufficient guarantee against<br />

corrosion place a diaphragm seal between gauge and pipe (consult<br />

our chemical seals/accessories manual).<br />

Parts of the diaphragm seal in contact with fluid (bottom housing,<br />

diaphragm intermediate ring) are made of a material withstanding<br />

corrosive fluids : steel, stainless steel, nickel, tantalum etc... or coated<br />

with corrosion-proof materials (Teflon, halar, Kel F, etc).<br />

Bottom housing can be made of carbon steel, stainless steel,<br />

hastelloy B or C, tantalum, etc.<br />

NO<br />

NO<br />

YES<br />

NO YES NO<br />

Pulsations<br />

Corrosivefluids<br />

YES<br />

Oil filled gauge<br />

Dampener<br />

Diaphragm<br />

seal

Excessive temperatures must be avoided<br />

If the joining is soft-soldered the gauge must not be<br />

subjected to a permanent temperature over 80˚C (180 ˚F).<br />

If the joining is brazed the gauge must not be<br />

subjected<br />

to a permanent temperature over 120˚C (270˚F).<br />

If the joining is arc-welded (st.steel tube) the gauge<br />

must not be subjected to a permanent temperature over 250˚C (482˚F)<br />

NOTE : The mentioned temperatures are temperatures inside the<br />

BOURDON tube.<br />

Overpressure<br />

Before calibration all our Bourdon tubes are subjected to an<br />

overload test, so that in normal utilization our gauges should be<br />

able to withstand the following overpressure without any damage.<br />

30% of maximum graduation up to 100 bar.<br />

15% of maximum graduation over 100 bar.<br />

A short pipe of small section, placed in between the hot fluid and the<br />

pressure gauge is sometimes efficient enough to lower the<br />

temperature to acceptable values. A siphon, especially on vapor,<br />

can be used after having been initially filled by a fluid condensed at<br />

cold temperatures. In this case, do not purge the siphon. In all cases,<br />

the first pressure increase must be carried out slowly to enable<br />

the hot fluid to cool off.<br />

Diaphragm and lower housing materials<br />

Siphon<br />

Hot fluid<br />

Overload<br />

device<br />

This choice is directly linked to the aggressivity of the fluid to be measured. Corrosion however depends also on surface<br />

condition of the parts subjected to a corrosive agent, on the circulation of air (hence of oxygen) dissolved in the fluid, on<br />

the presence of catalytic agents or conversely of corrosion inhibitors.<br />

The following table provides general indications of compatibility. Considering the complexity of corrosion phenomena, it is<br />

mandatory to check the choice of material (T., concentration, pressure, shape... influences).<br />

MATERIALS<br />

316 L Stainless steel<br />

TO BE USED WITH :<br />

-Strong<br />

ones)<br />

and weak acids (except mineral<br />

-Strong<br />

-Acid, neutral<br />

and weak<br />

or basic<br />

bases<br />

-Sea water<br />

salts<br />

-Oxidizing<br />

-Hydrogen<br />

media<br />

DO NOT USE WITH :<br />

-T<br />

-Strong<br />

fluid ><br />

oxidizing<br />

100˚C<br />

high concentrations<br />

agents at<br />

-Hydrochloric<br />

acids in concentrations<br />

and sulphuric<br />

-Ferric chloride<br />

> 2% and T > 20˚C<br />

-Fluorine,<br />

-Wet chlorine<br />

fluoride<br />

-Concentrated<br />

-Oxalic and chromic<br />

nitric acid<br />

acids<br />

at high temperature<br />

<strong>PRESSURE</strong>

<strong>PRESSURE</strong><br />

MATERIALS<br />

MONEL 400<br />

HASTELLOY B<br />

HASTELLOY B2<br />

HASTELLOY C 276<br />

URANUS B 6<br />

TITANIUM<br />

TO BE USED WITH :<br />

-Hydrogen sulphide (often<br />

found in petroleum products)<br />

-Sea water<br />

-Neutral and alkaline salts<br />

-Hyarofluoric acid<br />

-Specifically designed for hydrochloric<br />

acid at high concentration and<br />

temperature<br />

-For pitted corrosion in the<br />

areas near the solders hydrochloric,<br />

sulphuric, acetic acids at high<br />

concentrations and temperature<br />

Sulphuric acid at high concentration<br />

and temperature<br />

-Wet chlorine<br />

-Ferric chloride<br />

-Copper salts<br />

-Strong oxidizing agents<br />

-Waste incineration gas<br />

-Warm sulphuric acid (

<strong>PRESSURE</strong><br />

<strong>PRESSURE</strong> CONVERSION CHART<br />

CONVERSION TABLE<br />

PSI<br />

1<br />

14.696<br />

14.2233<br />

0.036092<br />

0.019336<br />

0.491154<br />

0.145<br />

14.5038<br />

0.00142<br />

ATM<br />

0.068046<br />

1<br />

0.96784<br />

0.002454<br />

0.001315<br />

0.0033421<br />

0.00987<br />

0.98692<br />

0.000097<br />

kg/cm2<br />

0.070307<br />

1.0332<br />

1<br />

0.00253<br />

0.001359<br />

0.03453<br />

0.010197<br />

1.01972<br />

0.0001<br />

in.H2O<br />

27.7276<br />

407.484<br />

394.38<br />

1<br />

0.53616<br />

13.6185<br />

4.0186<br />

402.156<br />

0.03937<br />

mmHg<br />

51.715<br />

760<br />

735.559<br />

1.8651<br />

1<br />

25.4<br />

7.5006<br />

750.062<br />

0.0734<br />

in.Hg<br />

2.03602<br />

29.921<br />

28.959<br />

0.07343<br />

0.03937<br />

1<br />

0.2953<br />

29.53<br />

0.0029<br />

kPa<br />

6.895<br />

101.325<br />

98.096<br />

0.249<br />

0.1333<br />

3.3864<br />

1<br />

100<br />

0.0098<br />

Bar<br />

0.06895<br />

1.01325<br />

0.98067<br />

0.00249<br />

0.001333<br />

0.033864<br />

0.01<br />

1<br />

0.000098<br />

mmH2O<br />

704.28104<br />

10350.0936<br />

10000<br />

25.4<br />

13.618464<br />

345.9099<br />

102.07244<br />

10214.7624<br />

1<br />

DENSITY CONVERSION CHART<br />

lb/ft3<br />

1<br />

62.43<br />

0.06243<br />

1728<br />

gm/cm2<br />

0.016018<br />

1<br />

0.001<br />

27.68<br />

kg/m3<br />

16.0184<br />

1000<br />

1<br />

27679.8<br />

lb/in3<br />

0.000578<br />

0.03613<br />

0.000036<br />

1<br />

VOLUME CONVERSION CHART<br />

GALLON<br />

(U.S)<br />

1<br />

7.481<br />

0.004329<br />

42<br />

0.000264<br />

264.17<br />

0.264<br />

1.201<br />

CUBIC<br />

FEET<br />

0.1337<br />

1<br />

0.000578<br />

5.615<br />

0.000035<br />

35.3144<br />

0.0353<br />

0.1606<br />

CUBIC<br />

INCHES<br />

231<br />

1728<br />

1<br />

9702<br />

0.06102<br />

61023<br />

61.03<br />

277.4<br />

BARRELS<br />

(OIL)<br />

0.02381<br />

0.1781<br />

0.000103<br />

1<br />

0.000006<br />

6.2906<br />

0.0629<br />

0.0286<br />

CUBIC<br />

CM<br />

3785<br />

28320<br />

16.39<br />

159000<br />

1<br />

1000000<br />

1000<br />

4546<br />

CUBIC<br />

METER<br />

0.003785<br />

0.02832<br />

0.000016<br />

0.159<br />

0.000001<br />

1<br />

0.001<br />

0.004546<br />

LITER<br />

3.785<br />

28.32<br />

0.01639<br />

158.94<br />

0.001<br />

1000<br />

1<br />

4.546<br />

IMP.<br />

GALLON<br />

0.8327<br />

6.229<br />

0.003605<br />

34.97<br />

0.00022<br />

220.1<br />

0.22<br />

1<br />

MASS CONVERSION CHART<br />

lb.<br />

1<br />

0.0625<br />

2.205<br />

0.002205<br />

8.345<br />

2240<br />

2204.6<br />

2000<br />

oz.<br />

16<br />

1<br />

35.27<br />

0.03527<br />

133.5<br />

35840<br />

35273<br />

32000<br />

kg<br />

0.4536<br />

0.02835<br />

1<br />

0.001<br />

3.785<br />

1016.4<br />

1000<br />

907.03<br />

gm<br />

453.6<br />

28.35<br />

1000<br />

1<br />

3785<br />

1016363<br />

1000000<br />

909090.9<br />

gal H2O<br />

(32F)<br />

0.1198<br />

0.00749<br />

0.2642<br />

0.000264<br />

1<br />

268.352<br />

264.11<br />

239.7<br />

long<br />

ton<br />

0.000446<br />

0.000027<br />

0.009839<br />

0.000000<br />

0.003726<br />

1<br />

0.9842<br />

0.892857<br />

metric<br />

tonne<br />

0.000453<br />

0.000028<br />

0.001<br />

0.000001<br />

0.003786<br />

1.016<br />

1<br />

0.907194<br />

ton<br />

0.0005<br />

0.000031<br />

0.001102<br />

0.000001<br />

0.004171<br />

1.12<br />

1.1023<br />

1

GENERAL SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P110 SERIES<br />

SERVICE INTENDED<br />

P110 Series, General Service Pressure gauge,<br />

Feature low Cost and high quality and is suitable for non-corrosive fluid<br />

Air, Oil, Gas or Water service are the most common applications.<br />

NOMINAL DIAMETER<br />

40, 50, 60, 75, 100, 150, and 200mm<br />

ACCURACY<br />

40mm : ±3.0% of Full Scale<br />

50, 60, 75, 100, 150, and 200mm : ±1.5% of Full Scale<br />

SCALE RANGE<br />

40mm : 0~2 to 0~35kgf/cm 2<br />

50mm : 0~2 to 0~100kgf/cm 2<br />

65, 75mm : -76cmHg ~ 0 to 0 ~ 250kgf/cm 2<br />

100mm(New) : -76cmHg ~ 0 to 0 ~ 350kgf/cm 2<br />

100mm, 150mm : -76cmHg ~ 0 to 0 ~ 1000kgf/cm 2<br />

200mm : -76cmHg ~ 0 to 0 ~ 250kgf/cm 2<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -5 ~ 40˚C<br />

DEGREE OF PROTECTION<br />

IP44<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

Brass<br />

ELEMENT<br />

40, 50mm : Brass<br />

60, 75, 100mm(New) : ≤100kgf/cm 2 : Brass<br />

>100kgf/cm 2 : 316SS<br />

100, 150, 200mm : ≤35kgf/cm 2 : Brass<br />

>35kgf/cm 2 : 316SS<br />

C Type Bourdon Tube<br />

CASE<br />

Black Finished Steel<br />

Black Finished Aluminium(Diameter 200mm)<br />

WINDOW<br />

Glass<br />

MOVEMENT<br />

Brass<br />

COVER<br />

Black Finished Steel<br />

DIAL<br />

White Aluminium with<br />

Black Graduations<br />

POINTER<br />

Aluminium alloy, Black painted<br />

PROCESS CONNECTION<br />

40mm : 1/8” PT, NPT &PF<br />

50mm : 1/4”, 1/8” PT, NPT &PF<br />

60mm : 1/4” PT, NPT &PF<br />

75, 100mm(New) : 3/8” PT, NPT &PF<br />

100mm, 150 and 200mm : 1/2”, 3/8” PT, NPT & PF<br />

PD01-01

PD01-01<br />

ORDERING INFORMATION<br />

BASE<br />

P110 :<br />

MODEL<br />

GENERAL SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

0 : 40mm<br />

1 : 50mm<br />

2 : 60mm<br />

3 : 75mm<br />

4 : 100mm<br />

6 : 150mm<br />

7 : 200mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct, Not available with Diameter 200mm<br />

B : Bottom Connection, Surface, Case Mounting Plate, Not available with Diameter 40mm<br />

F : Centre Back Connection, Direct, Not available with Diameter 100mm,and 150mm and 200mm<br />

G : Lower Back Connection, Direct, Only available with Diameter 100mm(New),100mm and 200mm<br />

J : Centre Back Connection, Flush, Cover Mounting Plate, Not available with Diameter 40mm 100mm, 150mm<br />

and 200mm<br />

N : Lower Back Connection, Cover Mounting Plate, Only available with Diameter 100mm(New) and<br />

150mm<br />

ACCURACY<br />

PROCESS CONNECTION<br />

4 : ±1.5% of Full Scale. Not available with diameter 40mm<br />

6 : ±3.0% of Full Scale<br />

B : 1/8”, Only available with diameter 40,50mm<br />

C : 1/4”, Only available with diameter 50,60mm<br />

D : 3/8”, Not available with diameter 40,50,75mm<br />

E : 1/2”, Only available with diameter 100,150,200mm<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

Z : Other (See Note 1)<br />

UNIT<br />

B : kgf/cm 2 (Pressure) or cmHg + kgf/cm 2 (Compound)<br />

C: cmHg, Only available with vacuum gauge<br />

Z : Other<br />

RANGE<br />

DIAL COLOR<br />

Refer to Pressure Range Table<br />

P110 0 A 6 B C B 041 1 0<br />

Note 1, Special connection type is available such as BSP & BSPT<br />

1 : 2 Colors<br />

5 : 3 Colors, Available with<br />

Compound & Vacuum Gauges<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P110 : TYPE OF MOUNTING MOUNTING<br />

PD01-01

AMMONIA SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P111 SERIES<br />

SERVICE INTENDED<br />

The P111 Series are designed to withstand the shock, vibration<br />

and pulsation inherent in agricultural ammonia equipment.<br />

NOMINAL DIAMETER<br />

75 and 100mm<br />

ACCURACY<br />

±1.5% of Full Scale<br />

SCALE RANGE<br />

-76cmHg ~ 10, 15, 25kgf/cm 2<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -5 ~ 40˚C<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

304SS<br />

ELEMENT<br />

316SS<br />

C Type Bourdon Tube<br />

CASE<br />

Black Finished Steel<br />

COVER<br />

Black Finished Steel<br />

WINDOW<br />

Glass<br />

MOVEMENT<br />

Brass<br />

DIAL<br />

White Aluminium with<br />

Black Graduations<br />

POINTER<br />

Aluminium alloy, Black painted<br />

PROCESS CONNECTION<br />

3/8”<br />

CONNECTION<br />

PF, PT<br />

PD01-02

PD01-02<br />

ORDERING INFORMATION<br />

BASE<br />

P111 :<br />

MODEL<br />

AMMONIA SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

3 : 75mm<br />

4 : 100 mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

M : Lower Back Connection, Flush, Case Centre Mounting Bracket.Only available with<br />

Diameter 100mm<br />

ACCURACY<br />

4 : ±1.5% of Full Scale<br />

CONNECTION<br />

D : 3/8”<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

UNIT<br />

B : cmHg + kgf/cm 2<br />

(Compound)<br />

RANGE<br />

032 : -76 ~ 10<br />

033 : -76 ~ 15<br />

034 : -76 ~ 20<br />

DIAL COLOR<br />

6 : 3 Colors<br />

OPTIONS<br />

P111 4 A 4 D B B 032 6 0<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P111 : TYPE OF MOUNTING MOUNTING<br />

PD01-02

<strong>PRESSURE</strong> CONVERSION CHART<br />

CONVERSION TABLE<br />

PSI<br />

1<br />

14.696<br />

14.2233<br />

0.036092<br />

0.019336<br />

0.491154<br />

0.145<br />

14.5038<br />

0.00142<br />

ATM<br />

0.068046<br />

1<br />

0.96784<br />

0.002454<br />

0.001315<br />

0.0033421<br />

0.00987<br />

0.98692<br />

0.000097<br />

kg/cm2<br />

0.070307<br />

1.0332<br />

1<br />

0.00253<br />

0.001359<br />

0.03453<br />

0.010197<br />

1.01972<br />

0.0001<br />

in.H2O<br />

27.7276<br />

407.484<br />

394.38<br />

1<br />

0.53616<br />

13.6185<br />

4.0186<br />

402.156<br />

0.03937<br />

mmHg<br />

51.715<br />

760<br />

735.559<br />

1.8651<br />

1<br />

25.4<br />

7.5006<br />

750.062<br />

0.0734<br />

in.Hg<br />

2.03602<br />

29.921<br />

28.959<br />

0.07343<br />

0.03937<br />

1<br />

0.2953<br />

29.53<br />

0.0029<br />

kPa<br />

6.895<br />

101.325<br />

98.096<br />

0.249<br />

0.1333<br />

3.3864<br />

1<br />

100<br />

0.0098<br />

Bar<br />

0.06895<br />

1.01325<br />

0.98067<br />

0.00249<br />

0.001333<br />

0.033864<br />

0.01<br />

1<br />

0.000098<br />

mmH2O<br />

704.28104<br />

10350.0936<br />

10000<br />

25.4<br />

13.618464<br />

345.9099<br />

102.07244<br />

10214.7624<br />

1<br />

DENSITY CONVERSION CHART<br />

lb/ft3<br />

1<br />

62.43<br />

0.06243<br />

1728<br />

gm/cm2<br />

0.016018<br />

1<br />

0.001<br />

27.68<br />

kg/m3<br />

16.0184<br />

1000<br />

1<br />

27679.8<br />

lb/in3<br />

0.000578<br />

0.03613<br />

0.000036<br />

1<br />

VOLUME CONVERSION CHART<br />

GALLON<br />

(U.S)<br />

1<br />

7.481<br />

0.004329<br />

42<br />

0.000264<br />

264.17<br />

0.264<br />

1.201<br />

CUBIC<br />

FEET<br />

0.1337<br />

1<br />

0.000578<br />

5.615<br />

0.000035<br />

35.3144<br />

0.0353<br />

0.1606<br />

CUBIC<br />

INCHES<br />

231<br />

1728<br />

1<br />

9702<br />

0.06102<br />

61023<br />

61.03<br />

277.4<br />

BARRELS<br />

(OIL)<br />

0.02381<br />

0.1781<br />

0.000103<br />

1<br />

0.000006<br />

6.2906<br />

0.0629<br />

0.0286<br />

CUBIC<br />

CM<br />

3785<br />

28320<br />

16.39<br />

159000<br />

1<br />

1000000<br />

1000<br />

4546<br />

CUBIC<br />

METER<br />

0.003785<br />

0.02832<br />

0.000016<br />

0.159<br />

0.000001<br />

1<br />

0.001<br />

0.004546<br />

LITER<br />

3.785<br />

28.32<br />

0.01639<br />

158.94<br />

0.001<br />

1000<br />

1<br />

4.546<br />

IMP.<br />

GALLON<br />

0.8327<br />

6.229<br />

0.003605<br />

34.97<br />

0.00022<br />

220.1<br />

0.22<br />

1<br />

MASS CONVERSION CHART<br />

lb.<br />

1<br />

0.0625<br />

2.205<br />

0.002205<br />

8.345<br />

2240<br />

2204.6<br />

2000<br />

oz.<br />

16<br />

1<br />

35.27<br />

0.03527<br />

133.5<br />

35840<br />

35273<br />

32000<br />

kg<br />

0.4536<br />

0.02835<br />

1<br />

0.001<br />

3.785<br />

1016.4<br />

1000<br />

907.03<br />

gm<br />

453.6<br />

28.35<br />

1000<br />

1<br />

3785<br />

1016363<br />

1000000<br />

909090.9<br />

gal H2O<br />

(32F)<br />

0.1198<br />

0.00749<br />

0.2642<br />

0.000264<br />

1<br />

268.352<br />

264.11<br />

239.7<br />

long<br />

ton<br />

0.000446<br />

0.000027<br />

0.009839<br />

0.000000<br />

0.003726<br />

1<br />

0.9842<br />

0.892857<br />

metric<br />

tonne<br />

0.000453<br />

0.000028<br />

0.001<br />

0.000001<br />

0.003786<br />

1.016<br />

1<br />

0.907194<br />

ton<br />

0.0005<br />

0.000031<br />

0.001102<br />

0.000001<br />

0.004171<br />

1.12<br />

1.1023<br />

1

FREON MODEL GAS : P112 SERVICE SERIES<strong>PRESSURE</strong> <strong>GAUGE</strong><br />

PD01-03<br />

SERVICE INTENDED<br />

P112 Series are designed for withstanding shock,<br />

vibration and pulsation for freon gas services.<br />

NOMINAL DIAMETER<br />

60 and 75mm<br />

ACCURACY<br />

±1.5% of Full Scale<br />

SCALE RANGE<br />

60mm : -76cmHg ~ 10, 15, 20kgf/cm2 0 ~ 25, 0 ~ 35kgf/cm2 75mm : -76cmHg ~15kgf/cm2 0 ~ 35kgf/cm2 WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -5 ~ 40˚C<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

Brass<br />

ELEMENT<br />

Brass<br />

C Type Bourdon Tube<br />

CASE<br />

Black Finished Steel<br />

COVER<br />

Black Finished Steel<br />

MOVEMENT<br />

Brass<br />

DIAL<br />

White Aluminium with<br />

Black Graduations<br />

POINTER<br />

Aluminium alloy, Black painted<br />

PROCESS CONNECTION<br />

7/16”<br />

CONNECTION TYPE<br />

UNF

PD01-03<br />

ORDERING INFORMATION<br />

BASE<br />

P112 :<br />

MODEL<br />

FREON GAS SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 60mm<br />

3 : 75mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

B : Bottom Connection, Surface, Case Mounting Plate, Only available with diameter 60mm<br />

H : Centre Back Connection, Flush, Case Centre Mounting Plate<br />

ACCURACY<br />

4 : ±1.5% of Full Scale<br />

CONNECTION<br />

P : 7/16”<br />

CONNECTION TYPE<br />

E : UNF<br />

UNIT<br />

RANGE<br />

B : kgf/cm 2 (Pressure) or cmHg + kgf/cm 2 (Compound)<br />

Z : Other<br />

032 : -76cmHg~10kgf/cm 2<br />

/Not available with diameter 75mm<br />

033 : -76cmHg~15kgf/cm 2<br />

034 : -76cmHg~20kgf/cm 2<br />

/Not available with diameter 75mm<br />

052 : 0~25kgf/cm 2<br />

/Not available with diameter 75mm<br />

054 : 0~35kgf/cm 2<br />

DIAL COLOR<br />

P112 2 H 4 P E B 033 5 0<br />

1 : 2 Colors<br />

5 : 3 Colors,<br />

Available with compound gauges<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P112 : TYPE OF MOUNTING<br />

PD01-03

<strong>PRESSURE</strong> CONVERSION CHART<br />

CONVERSION TABLE<br />

PSI<br />

1<br />

14.696<br />

14.2233<br />

0.036092<br />

0.019336<br />

0.491154<br />

0.145<br />

14.5038<br />

0.00142<br />

ATM<br />

0.068046<br />

1<br />

0.96784<br />

0.002454<br />

0.001315<br />

0.0033421<br />

0.00987<br />

0.98692<br />

0.000097<br />

kg/cm2<br />

0.070307<br />

1.0332<br />

1<br />

0.00253<br />

0.001359<br />

0.03453<br />

0.010197<br />

1.01972<br />

0.0001<br />

in.H2O<br />

27.7276<br />

407.484<br />

394.38<br />

1<br />

0.53616<br />

13.6185<br />

4.0186<br />

402.156<br />

0.03937<br />

mmHg<br />

51.715<br />

760<br />

735.559<br />

1.8651<br />

1<br />

25.4<br />

7.5006<br />

750.062<br />

0.0734<br />

in.Hg<br />

2.03602<br />

29.921<br />

28.959<br />

0.07343<br />

0.03937<br />

1<br />

0.2953<br />

29.53<br />

0.0029<br />

kPa<br />

6.895<br />

101.325<br />

98.096<br />

0.249<br />

0.1333<br />

3.3864<br />

1<br />

100<br />

0.0098<br />

Bar<br />

0.06895<br />

1.01325<br />

0.98067<br />

0.00249<br />

0.001333<br />

0.033864<br />

0.01<br />

1<br />

0.000098<br />

mmH2O<br />

704.28104<br />

10350.0936<br />

10000<br />

25.4<br />

13.618464<br />

345.9099<br />

102.07244<br />

10214.7624<br />

1<br />

DENSITY CONVERSION CHART<br />

lb/ft3<br />

1<br />

62.43<br />

0.06243<br />

1728<br />

gm/cm2<br />

0.016018<br />

1<br />

0.001<br />

27.68<br />

kg/m3<br />

16.0184<br />

1000<br />

1<br />

27679.8<br />

lb/in3<br />

0.000578<br />

0.03613<br />

0.000036<br />

1<br />

VOLUME CONVERSION CHART<br />

GALLON<br />

(U.S)<br />

1<br />

7.481<br />

0.004329<br />

42<br />

0.000264<br />

264.17<br />

0.264<br />

1.201<br />

CUBIC<br />

FEET<br />

0.1337<br />

1<br />

0.000578<br />

5.615<br />

0.000035<br />

35.3144<br />

0.0353<br />

0.1606<br />

CUBIC<br />

INCHES<br />

231<br />

1728<br />

1<br />

9702<br />

0.06102<br />

61023<br />

61.03<br />

277.4<br />

BARRELS<br />

(OIL)<br />

0.02381<br />

0.1781<br />

0.000103<br />

1<br />

0.000006<br />

6.2906<br />

0.0629<br />

0.0286<br />

CUBIC<br />

CM<br />

3785<br />

28320<br />

16.39<br />

159000<br />

1<br />

1000000<br />

1000<br />

4546<br />

CUBIC<br />

METER<br />

0.003785<br />

0.02832<br />

0.000016<br />

0.159<br />

0.000001<br />

1<br />

0.001<br />

0.004546<br />

LITER<br />

3.785<br />

28.32<br />

0.01639<br />

158.94<br />

0.001<br />

1000<br />

1<br />

4.546<br />

IMP.<br />

GALLON<br />

0.8327<br />

6.229<br />

0.003605<br />

34.97<br />

0.00022<br />

220.1<br />

0.22<br />

1<br />

MASS CONVERSION CHART<br />

lb.<br />

1<br />

0.0625<br />

2.205<br />

0.002205<br />

8.345<br />

2240<br />

2204.6<br />

2000<br />

oz.<br />

16<br />

1<br />

35.27<br />

0.03527<br />

133.5<br />

35840<br />

35273<br />

32000<br />

kg<br />

0.4536<br />

0.02835<br />

1<br />

0.001<br />

3.785<br />

1016.4<br />

1000<br />

907.03<br />

gm<br />

453.6<br />

28.35<br />

1000<br />

1<br />

3785<br />

1016363<br />

1000000<br />

909090.9<br />

gal H2O<br />

(32F)<br />

0.1198<br />

0.00749<br />

0.2642<br />

0.000264<br />

1<br />

268.352<br />

264.11<br />

239.7<br />

long<br />

ton<br />

0.000446<br />

0.000027<br />

0.009839<br />

0.000000<br />

0.003726<br />

1<br />

0.9842<br />

0.892857<br />

metric<br />

tonne<br />

0.000453<br />

0.000028<br />

0.001<br />

0.000001<br />

0.003786<br />

1.016<br />

1<br />

0.907194<br />

ton<br />

0.0005<br />

0.000031<br />

0.001102<br />

0.000001<br />

0.004171<br />

1.12<br />

1.1023<br />

1

GENERAL PURPOSE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P140 SERIES<br />

SERVICE INTENDED<br />

P140 Series, General Purpose Pressure Gauge, resists against<br />

weather and rust under the chemical and petrochemical<br />

circumstances allowing continuos exposure to atmosphere.<br />

NOMINAL DIAMETER<br />

40, 50, 60 and 100mm<br />

ACCURACY<br />

40mm : ±3.0% of Full Scale<br />

50, 60 and 100mm : ±1.5% of Full Scale<br />

SCALE RANGE<br />

40mm : 0 ~ 2 to 0 ~ 35kgf/cm2 50mm : 0 ~ 2 to 0 ~ 100kgf/cm2 60mm : -76cmHg ~ 0 to 0 ~ 250kgf/cm2 100mm : -76cmHg ~ 0 to 0 ~ 350kgf/cm2 WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -5 ~ 40˚C<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

Brass<br />

ELEMENT<br />

40 and 50mm : Brass<br />

60 and 100mm : ≤100kgf/cm 2 : Brass<br />

>100kgf/cm 2 : 316SS<br />

CASE<br />

Polycarbonate<br />

COVER & WINDOW<br />

Polycarbonate<br />

MOVEMENT<br />

Brass<br />

DIAL<br />

White Aluminium with<br />

Black Graduations<br />

POINTER<br />

Aluminium alloy, Black painted<br />

CONNECTION<br />

40mm : 1/8” PT, NPT & PF<br />

50mm : 1/4” PT, NPT & PF<br />

60mm : 1/4” PT, NPT & PF<br />

100mm : 3/8” PT, NPT & PF<br />

PD01-04

PD01-04<br />

ORDERING INFORMATION<br />

BASE<br />

P140 :<br />

MODEL<br />

GENERAL PURPOSE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

0 : 40mm<br />

1 : 50mm<br />

2 : 60mm<br />

4 : 100mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct, Not available with diameter 40m and 50mm<br />

F : Centre Back Connection, Direct, Not available with diameter 60mm and 100mm<br />

ACCURACY<br />

4 : ±1.5% of Full Scale, Not available with diameter 40mm<br />

6 : ±3.0% of Full Scale, Only available with diameter 40mm<br />

CONNECTION<br />

B : 1/8” Only available with diameter 40,mm<br />

C : 1/4” Only available with diameter 50,60mm<br />

D : 3/8” Not available with diameter 40,50,60mm<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

Z : Other<br />

UNIT<br />

B : kgf/cm 2 (Pressure) or cmHg + kgf/cm 2 (Compound)<br />

C: cmHg, Only available with vacuum gauge<br />

Z : Other<br />

RANGE<br />

Refer to Pressure Range Table<br />

DIAL COLOR<br />

P140 0 F 6 B C B 042 1 0<br />

1 : 2 Colors<br />

5 : 3 Colors, Available with<br />

Compound and Vacuum gauge<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P140 : TYPE OF MOUNTING<br />

PD01-04

INDUSTRIAL <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P220 SERIES<br />

SERVICE INTENDED<br />

The P220 Series are suitable for corrosive environment. Typical applications<br />

include : chemical, petrochemical, refining, power & marine industry.<br />

Its Stainless steel case and cover have good appearance<br />

and excellent proof to corrosion & chemical attack.<br />

NOMINAL DIAMETER<br />

60, 100 and 150mm<br />

ACCURACY<br />

60mm : ±1.5% of Full Scale<br />

100 and 150mm : ±1.0% of Full Scale<br />

SCALE RANGE<br />

60mm : -76cmHg ~ 0 to 0 ~ 250kgf/cm 2<br />

100mm and 150mm : -76cmHg ~ 0 to 0 ~ 2000kgf/cm 2<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -20 ~ 80˚C<br />

DEGREE OF PROTECTION<br />

IP65<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

316SS<br />

ELEMENT<br />

316SS<br />

PD02-01<br />

ORDERING INFORMATION<br />

BASE<br />

P220 :<br />

MODEL<br />

INDUSTRIAL <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 60mm<br />

4 : 100mm<br />

6 : 150mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

G : Lower Back Connection, Direct<br />

L : Lower Back Connection, Flush, Case Centre Mounting Plate, Not available with diameter 150mm<br />

M : Lower Back Connection, Flush, Case Centre Mounting Bracket<br />

ACCURACY<br />

3 : ±1.0% of Full Scale, Not available with diameter 60mm<br />

4 : ±1.5% of Full Scale.<br />

CONNECTION<br />

C : 1/4, Only available with diameter 60mm<br />

D : 3/8, Not available with diameter 60mm<br />

E : 1/2, Not available with diameter 60mm<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

Z : Other<br />

UNIT<br />

B : kgf/cm 2 (Pressure) or cmHg + kgf/cm 2 (Compound)<br />

C: cmHg, Only available with vacuum gauge<br />

Z : Other<br />

RANGE<br />

DIAL COLOR<br />

Refer to Pressure Range Table<br />

P220 4 A 3 E C B 041 3 0<br />

3 : 2 Colors<br />

7 : 3 Colors, Available with<br />

Compound and Vacuum Gauges<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P220 : TYPE OF MOUNTING<br />

PD02-01

INDUSTRIAL SERVICE <strong>PRESSURE</strong> GUAGE<br />

MODEL : P221 SERIES<br />

SERVICE INTENDED<br />

The P221Series are suitable for corrosive enviornment<br />

and chemical, petro-chemical, refining, power, marine & foods.<br />

Its Stainless steel case and cover offer good appearance<br />

and excellent proof to corrosion & chemical attack.<br />

NOMINAL DIAMETER<br />

40 and 50mm<br />

ACCURACY<br />

40mm : ± 3.0% of Full Scale<br />

50mm : ± 1.5% of Full Scale<br />

SCALE RANGE<br />

0~2, 4, 6, 10kg/cm 2<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -40 ~ 80˚C<br />

Fluid : -20 ~ 200˚C<br />

DEGREE OF PROTECTION<br />

IP65<br />

Over Range Protection : 130% of Full Scale<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

316SS<br />

ELEMENT 316S<br />

C Type Bourdon Tube<br />

CASE & BEZEL RING<br />

40mm : 304SS & Polycarbonate<br />

50mm : 304SS & 304SS<br />

WINDOW<br />

Polycarbonate<br />

MOVEMENT<br />

Stainless Steel<br />

DIAL<br />

White Aluminium with Black Lettering,<br />

POINTER<br />

Aluminium alloy, Black painted<br />

PROCESS CONNECTION<br />

1/8”, 1/4” PT, NPT & PF<br />

PD02-02

PD02-02<br />

ORDERING INFORMATION<br />

BASE MODEL<br />

P221 : INDUSTRIAL SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

0 : 40mm<br />

1 : 50mm<br />

MOUNTING TYPE(Refer to Mounting Type & Dimension)<br />

A : Bottom Connection, Direct, Not available with diameter 40mm<br />

F : Center Back Connection, Direct<br />

ACCURACY<br />

4 : ±1.5% of Full Scale, Only available with diameter 50mm<br />

6 : ±3.0% of Full Scale, Only available with diameter 40mm<br />

CONNECTION<br />

B : 1/8”<br />

C : 1/4”<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

Z : Other<br />

UNIT<br />

B : kg/cm 2<br />

RANGE<br />

042 : 0~2<br />

044 : 0~4<br />

045 : 0~6<br />

047 : 0~10<br />

P220 1 F 4 C D B 047 3 0<br />

DIAL COLOR<br />

3 : 2 Colors<br />

OPTIONS<br />

O : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P221 : TYPE OF MOUNTING<br />

PD02-02

PD02-03<br />

ORDERING INFORMATION<br />

BASE MODEL<br />

P222 : INDUSTRIAL SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

5 : 4 1/2 inch( 130 mm )<br />

MOUNTING TYPE(Refer to Mounting Type & Dimension)<br />

A : Bottom entry<br />

ACCURACY<br />

3 : ±1.0% of Full Scale<br />

CONNECTION<br />

D : 3/8”<br />

E : 1/2”<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

F : BSPT<br />

G : BSP<br />

Z : Other<br />

UNIT<br />

B : kg/cm 2<br />

L : kg/cm 2 & Psi<br />

RANGE<br />

Brefer to Pressure Range Table<br />

DIAL COLOR<br />

3 : 2 Colors<br />

7 : 3 Colors<br />

P220 A 3 E D L 047 3 O<br />

OPTIONS<br />

O : None<br />

1 : Accessories<br />

5 SAMPLE MODEL NUMMBER

P2205: P2205: TYPE TYPE OF OF MOUNTING<br />

MOUNTING<br />

PD02-03

LIQUID FILLED INDUSTRIAL <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P290 SERIES<br />

SERVICE INTENDED<br />

The P290 Series are designed to extend service life wherever<br />

corrosive atmosphere and severe operation conditions such as<br />

in pump, compressors and machine tool applications.<br />

The filling liquid is to absorb effect of vibration and pulsation<br />

constantly bathing the internal with lubricant and providing<br />

steady pointer leading.<br />

NOMINAL DIAMETER<br />

60, 100 and 150mm<br />

ACCURACY<br />

60mm : ±1.5% of Full Scale<br />

100 and 150mm : ±1.0% of Full Scale<br />

SCALE RANGE<br />

60mm : -76cmHg ~ 0 to 0 ~ 250kgf/cm 2<br />

100mm and 150mm : -76cmHg ~ 0 to 0 ~ 2000kgf/cm 2<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -20 ~ 80˚C<br />

FILLING LIQUID<br />

Glycerine<br />

DEGREE PF PROTECTION<br />

IP65<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

316SS<br />

ELEMENT<br />

316SS<br />

PD02-04<br />

ORDERING INFORMATION<br />

BASE<br />

P290 :<br />

MODEL<br />

LIQUID FILLED INDUSTRIAL <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 60mm<br />

4 : 100mm<br />

6 : 150mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

G: Lower Back Connection, Direct<br />

L : Lower Back Connection, Flush, Case Centre Mounting Platz, Not available with diameter 150mm<br />

M: Lower Back Connection, Flush, Case Centre Mounting Bracket<br />

ACCURACY<br />

3 : ±1.0% of Full Scale, Not available with diameter 60mm<br />

4 : ±1.5% of Full Scale.<br />

CONNECTION<br />

C : 1/4, Only available with diameter 60mm<br />

D : 3/8, Not available with diameter 60mm<br />

E : 1/2, Not available with diameter 60mm<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

Z : Other<br />

UNIT<br />

B : kgf/cm 2 (Pressure) or cmHg + kgf/cm 2 (Compound)<br />

C : cmHg, Only available with vacuum gauge<br />

Z : Other<br />

RANGE<br />

Refer to Pressure Range Table<br />

DIAL COLOR<br />

P290 4 A 3 E C B 041 3 0<br />

3 : 2 Colors<br />

7 : 3 Colors, Available with Compound<br />

and Vacuum Gauges<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P290 : TYPE OF MOUNTING<br />

PD02-04

RECEIVER <strong>GAUGE</strong><br />

MODEL : P228 SERIES<br />

SERVICE INTENDED<br />

The P228 Series are designed to meet general requirements<br />

of the process lndustry and provide remote or local indication.<br />

NOMINAL DIAMETER<br />

100 and 150mm<br />

ACCURACY<br />

±1.0% of Full Scale<br />

SCALE RANGE<br />

0~10 Square Root Scale<br />

0~100% Linear Scale<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -20 ~ 80˚C<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

316SS<br />

ELEMENT<br />

316SS<br />

C Type Bourdon Tube<br />

CASE<br />

304SS<br />

WINDOW<br />

Tempered Safety Glass<br />

COVER 304SS<br />

Slip-on-Fit<br />

MOVEMENT<br />

304SS<br />

DIAL<br />

White Aluminium with<br />

Black Lettering<br />

POINTER<br />

304SS, Black painted<br />

PROCESS CONNECTION<br />

1/4” PT, NPT<br />

PROCESS INPUT<br />

0.2 ~ 1kgf/cm2 PD02-05

PD02-05<br />

ORDERING INFORMATION<br />

BASE<br />

P228 :<br />

MODEL<br />

RECEIVER <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

4 : 100mm<br />

6 : 150mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection,Surface, Case Mounting Plate<br />

G : Lower Back Connection, Direct<br />

L : Lower Back Connection, Surface, Case Mounting Plate, Not available with diameter 150mm<br />

M : Lower Back Connection, Flush, Case Centre Mounting Bracket<br />

ACCURACY<br />

3 : ±1.0% of Full Scale<br />

CONNECTION<br />

C : 1/4”<br />

CONNECTION TYPE<br />

C : PT<br />

D : NPT<br />

SCALE<br />

X : Square Root<br />

W: % Linear<br />

RANGE<br />

047 : 0 ~10, Square Root Scale Only<br />

058 : 0 ~100%, Linear Scale Only<br />

DIAL COLOR<br />

3 : 2Colors<br />

OPTIONS<br />

P228 4 A 3 C C X 047 3 0<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P228 : TYPE OF MOUNTING<br />

PD02-05

<strong>PRESSURE</strong> CONVERSION CHART<br />

CONVERSION TABLE<br />

PSI<br />

1<br />

14.696<br />

14.2233<br />

0.036092<br />

0.019336<br />

0.491154<br />

0.145<br />

14.5038<br />

0.00142<br />

ATM<br />

0.068046<br />

1<br />

0.96784<br />

0.002454<br />

0.001315<br />

0.0033421<br />

0.00987<br />

0.98692<br />

0.000097<br />

kg/cm2<br />

0.070307<br />

1.0332<br />

1<br />

0.00253<br />

0.001359<br />

0.03453<br />

0.010197<br />

1.01972<br />

0.0001<br />

in.H2O<br />

27.7276<br />

407.484<br />

394.38<br />

1<br />

0.53616<br />

13.6185<br />

4.0186<br />

402.156<br />

0.03937<br />

mmHg<br />

51.715<br />

760<br />

735.559<br />

1.8651<br />

1<br />

25.4<br />

7.5006<br />

750.062<br />

0.0734<br />

in.Hg<br />

2.03602<br />

29.921<br />

28.959<br />

0.07343<br />

0.03937<br />

1<br />

0.2953<br />

29.53<br />

0.0029<br />

kPa<br />

6.895<br />

101.325<br />

98.096<br />

0.249<br />

0.1333<br />

3.3864<br />

1<br />

100<br />

0.0098<br />

Bar<br />

0.06895<br />

1.01325<br />

0.98067<br />

0.00249<br />

0.001333<br />

0.033864<br />

0.01<br />

1<br />

0.000098<br />

mmH2O<br />

704.28104<br />

10350.0936<br />

10000<br />

25.4<br />

13.618464<br />

345.9099<br />

102.07244<br />

10214.7624<br />

1<br />

DENSITY CONVERSION CHART<br />

lb/ft3<br />

1<br />

62.43<br />

0.06243<br />

1728<br />

gm/cm2<br />

0.016018<br />

1<br />

0.001<br />

27.68<br />

kg/m3<br />

16.0184<br />

1000<br />

1<br />

27679.8<br />

lb/in3<br />

0.000578<br />

0.03613<br />

0.000036<br />

1<br />

VOLUME CONVERSION CHART<br />

GALLON<br />

(U.S)<br />

1<br />

7.481<br />

0.004329<br />

42<br />

0.000264<br />

264.17<br />

0.264<br />

1.201<br />

CUBIC<br />

FEET<br />

0.1337<br />

1<br />

0.000578<br />

5.615<br />

0.000035<br />

35.3144<br />

0.0353<br />

0.1606<br />

CUBIC<br />

INCHES<br />

231<br />

1728<br />

1<br />

9702<br />

0.06102<br />

61023<br />

61.03<br />

277.4<br />

BARRELS<br />

(OIL)<br />

0.02381<br />

0.1781<br />

0.000103<br />

1<br />

0.000006<br />

6.2906<br />

0.0629<br />

0.0286<br />

CUBIC<br />

CM<br />

3785<br />

28320<br />

16.39<br />

159000<br />

1<br />

1000000<br />

1000<br />

4546<br />

CUBIC<br />

METER<br />

0.003785<br />

0.02832<br />

0.000016<br />

0.159<br />

0.000001<br />

1<br />

0.001<br />

0.004546<br />

LITER<br />

3.785<br />

28.32<br />

0.01639<br />

158.94<br />

0.001<br />

1000<br />

1<br />

4.546<br />

IMP.<br />

GALLON<br />

0.8327<br />

6.229<br />

0.003605<br />

34.97<br />

0.00022<br />

220.1<br />

0.22<br />

1<br />

MASS CONVERSION CHART<br />

lb.<br />

1<br />

0.0625<br />

2.205<br />

0.002205<br />

8.345<br />

2240<br />

2204.6<br />

2000<br />

oz.<br />

16<br />

1<br />

35.27<br />

0.03527<br />

133.5<br />

35840<br />

35273<br />

32000<br />

kg<br />

0.4536<br />

0.02835<br />

1<br />

0.001<br />

3.785<br />

1016.4<br />

1000<br />

907.03<br />

gm<br />

453.6<br />

28.35<br />

1000<br />

1<br />

3785<br />

1016363<br />

1000000<br />

909090.9<br />

gal H2O<br />

(32F)<br />

0.1198<br />

0.00749<br />

0.2642<br />

0.000264<br />

1<br />

268.352<br />

264.11<br />

239.7<br />

long<br />

ton<br />

0.000446<br />

0.000027<br />

0.009839<br />

0.000000<br />

0.003726<br />

1<br />

0.9842<br />

0.892857<br />

metric<br />

tonne<br />

0.000453<br />

0.000028<br />

0.001<br />

0.000001<br />

0.003786<br />

1.016<br />

1<br />

0.907194<br />

ton<br />

0.0005<br />

0.000031<br />

0.001102<br />

0.000001<br />

0.004171<br />

1.12<br />

1.1023<br />

1<br />

PD02-05

TEST <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

STAINLESS STEEL CASE, MODEL : P229 SERIES<br />

ALUMINIUM CASE, MODEL : P335 SERIES<br />

SERVICE INTENDED<br />

The P229 and P335 series are designed for use<br />

in instrument shops, laboratories and other critical<br />

applications where a high degree of accuracy is<br />

required and operator error must be minimized.<br />

NOMINAL DIAMETER<br />

150mm<br />

ACCURACY<br />

±0.5% of Full Scale<br />

SCALE RANGE<br />

-76cmHg ~ 0 and<br />

0 ~ 1 to 0 ~ 350 kgf/cm 2<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -20 ~ 65˚C<br />

Fluid : -20 ~ 80˚C<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

304SS and 316SS<br />

ELEMENT<br />

316SS<br />

CASE<br />

304SS or Black Finished Aluminium<br />

COVER 304SS or Black Finished Aluminium<br />

WINDOW<br />

Glass<br />

MOVEMENT<br />

304SS<br />

DIAL<br />

White Aluminium with<br />

Black Graduations<br />

POINTER<br />

Aluminium alloy, Black painted<br />

PROCESS CONNECTION<br />

3/8”, 1/2” PT, NPT & PF<br />

PD02-06

PD02-06<br />

ORDERING INFORMATION<br />

BASE<br />

P229 :<br />

MODEL<br />

P335 : TEST TEST <strong>PRESSURE</strong> <strong>PRESSURE</strong> <strong>GAUGE</strong>, <strong>GAUGE</strong>, STAINLESS ALUMINIUM STEEL CASE CASE<br />

NOMINAL DIAMETER<br />

6 : 150mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

G : Lower Back Connection, Direct, Not available with P335<br />

M : Lower Back Connection, Flush, Case Centre Mounting Bracket<br />

ACCURACY<br />

2 : ±0.5% of Full Scale<br />

CONNECTION<br />

D : 3/8”<br />

E : 1/2”<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

UNIT<br />

B : kgf/cm 2<br />

C : cmHg, Only available with vacuum gauge<br />

Z : Other<br />

P229 6 A 2 E C C 047 2 0<br />

RANGE (Refer to Measuring Range Table)<br />

XXX<br />

<strong>PRESSURE</strong><br />

MAT’L & DIALS<br />

CONNECTION<br />

2 : 316SS & 2 Colors<br />

3 : 316SS & 2 Colors<br />

6 : 304SS & 3 Colors, Available with<br />

Compound and Vacuum Gauges<br />

7 : 316SS & 3 Colors, Available with<br />

Compound and Vacuum Gauges<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMMBER

P229, 335 : TYPE OF MOUNTING<br />

PD02-06

EURO <strong>GAUGE</strong>®<br />

INDUSTRIAL SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P252 SERIES<br />

SERVICE INTENDED<br />

The P252 Series are suitable for corrosive environment. Typical Application include :<br />

chemical, petrochemical, refining, power, marine or food industry.<br />

Its stainless steel case and cover offer good appearance<br />

and excellent proof to corrosion & chemical attack.<br />

NOMINAL DIAMETER<br />

63, 83, 100mm and 160mm<br />

ACCURACY<br />

Model : P2522(63mm) & P2523(80mm) : 1.6 PER DIN 16 005<br />

Model : P2524(100mm) & P2526(160mm) :<br />

1.0 PER DIN 16 005<br />

SCALE RANGE<br />

63mm and 80mm : -1 ~ 0 to 0 ~ 1000 bar<br />

100 and 160mm : -1 ~ 0 to 0~1600 bar<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -40~60˚C<br />

Fluid : +200˚C maximum<br />

DEGREE OF PROTECTION<br />

IP65<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

316SS, OPTION-316Ti(1.4571) and Monel<br />

Threaded entry, radial or back.<br />

ELEMENT<br />

316SS, OPTION-316Ti(1.4571) and Monel<br />

Model : P2534(100mm) & P2526(160mm)<br />

PD02-07<br />

ORDERING INFORMATION<br />

BASE MODEL<br />

P252 : INDUSTRIAL SERVICE <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 63mm<br />

3 : 80mm<br />

4 : 100mm<br />

6 : 160mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

F : Center back Connection, Direct, Only available with diameter 63mm<br />

G: Lower back Connection, Direct<br />

J : Center back Connection, Flush, Cover Mounting Plate, Only available with diameter 63mm<br />

N: Lower back Connection, Flush, Cover Mounting Plate<br />

ACCURACY<br />

3 : 1.0 Per DIN16 005, Not available with diameter 63mm & 80mm<br />

4 : 1.6 Per DIN16 005, Only available with diameter 63mm & 80mm<br />

CONNECTION<br />

C : 1/4”, Only available with diameter 63mm<br />

D : 3/8”, Not available with diameter 63mm<br />

E : 1/2”, Not available with diameter 63mm & 80mm<br />

CONNECTION TYPE<br />

B : PF<br />

C: PT<br />

D: NPT<br />

F : BSPT<br />

G: BSP<br />

Z : Other<br />

STEM OUTDIA.<br />

B : kgf/cm 2<br />

H : bar<br />

L : kgf/cm 2 & Psi<br />

RANGE<br />

P252 4 A 3 E D H 047 3 0<br />

<strong>PRESSURE</strong> MAT’L & DIALS CONNECTION<br />

Refer to Pressure Range Table<br />

3 : 316SS & 2 Colors<br />

4 : 316Ti & 2 Colors<br />

7 : 316SS & 3 Colors,<br />

Available with Compound and<br />

Vacuum Gauges<br />

8 : 316Ti & 3 Colors,<br />

Available with Compound and<br />

Vacuum Gauges<br />

Z : MONEL<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMBER

P252 P252 : TYPE TYPE OF OF MOUNTING<br />

MOUNTING<br />

PD02-07

EURO <strong>GAUGE</strong>®<br />

PROCESS INDUSTRY <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P253 SERIES<br />

SERVICE INTENDED<br />

The P253 Series are suitable for corrosive environment.<br />

Typical Application include : chemical, petrochemical, refining,<br />

power, marine or food industry.Its stainless steel case and cover<br />

offer good appearance and excellent proof to corrosion &<br />

chemical attack.<br />

NOMINAL DIAMETER<br />

63, 100mm<br />

ACCURACY<br />

Model : P2532(63mm) : 1.6 PER DIN 16 005<br />

Model : P2534(100mm) : 1.0 PER DIN 16 005<br />

SCALE RANGE<br />

63mm : -1~0 to 0~1000bar<br />

100mm : -1~0 to 0~1600bar<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -40~60˚C<br />

Fluid : +60˚C maximum<br />

DEGREE OF PROTECTION<br />

IP54<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

Cu Alloy 2.0460<br />

Threaded entry, Radial or back.<br />

ELEMENT<br />

Cu Alloy 2.0460<br />

Model : P2534(100mm)<br />

PD02-08<br />

ORDERING INFORMATION<br />

BASE<br />

P253 :<br />

MODEL<br />

PROCESS INDUSTRY <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

3 : 63mm<br />

4 : 100mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

F : Center back Connection, Direct, Only available with diameter 63mm<br />

G: Lower back Connection, Direct, Only available with diameter 100mm<br />

J : Center back Connection, Flush, Cover Mounting Plate, Only available with diameter 63mm<br />

N: Lower back Connection, Flush, Cover Mounting Plate, Only available with diameter 100mm<br />

ACCURACY<br />

3 : 1.0 Per DIN16 005, Not available with diameter 63mm<br />

4 : 1.6 Per DIN16 005, Only available with diameter 63mm<br />

CONNECTION<br />

C : 1/4”, Only available with diameter 63mm<br />

D : 3/8”, Not available with diameter 63mm<br />

E : 1/2”, Not available with diameter 63mm<br />

CONNECTION TYPE<br />

B : PF<br />

C: PT<br />

D: NPT<br />

F : BSPT<br />

G: BSP<br />

Z : Other<br />

UNIT<br />

B : kgf/cm 2<br />

H: bar<br />

L : kgf/cm 2 & Psi<br />

RANGE<br />

Refer to Pressure Range Table<br />

DIAL COLOR<br />

1 : 2 Colors<br />

5 : 3 Colors<br />

P253 4 A 3 E D H 047 1 0<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMBER

P253 : TYPE OF MOUNTING MOUNTING<br />

J<br />

PD02-08

PD02-09<br />

ORDERING INFORMATION<br />

BASE MODEL<br />

P257 : SOLID FRONT SAFETY <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 63mm<br />

4 : 100mm<br />

MOUNTING TYPE(Refer to Mounting Type & Dimension)<br />

A : Bottom entry<br />

G : Lower back entry<br />

M : Lower back entry & panel mounting flange with mounting bracket<br />

ACCURACY<br />

3 : 1.0 Per DIN16 005. Not available with diameter 63mm<br />

4 : 1.6 Per DIN16 005. Only available with diameter 63mm<br />

CONNECTION<br />

C : 1/4” Only available with diameter63mm<br />

D : 3/8” Not available with diameter 63mm<br />

E : 1/2” Not available with diameter 63mm<br />

CONNECTION TYPE<br />

B : PF<br />

C : PT<br />

D : NPT<br />

F : BSPT<br />

G : BSP<br />

Z : Other<br />

UNIT<br />

B : kg/cm 2<br />

H : bar<br />

L : Kg/cm 2 & Psi<br />

RANGE<br />

Refer to Pressure Range Table<br />

DIAL COLOR<br />

3 : 2 Colors<br />

7 : 3 Colors<br />

OPTIONS<br />

O : None<br />

1 : Liquid filling<br />

P257 4 A 3 E D L 146 3 0 SAMPLE MODEL NUMMBER

P257 : TYPE OF MOUNTING<br />

PD02-09

EURO <strong>GAUGE</strong>®<br />

LIQUID FILLED INDUSTRIAL <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P258 SERIES<br />

SERVICE INTENDED<br />

The P258 Series are suitable for corrosive environment.<br />

Typical application include : chemical, petrochemical, refining,<br />

power, marine or food indurstry.The filled liquid absorb<br />

vibration effect and pulsation pressure.<br />

NOMINAL DIAMETER<br />

63, 83, 100 and 160mm<br />

ACCURACY<br />

Model : P2522(63mm) & P2523(80mm) : 1.6 PER DIN 16 005<br />

Model : P2524(100mm) & P2526(160mm) :<br />

1.0 PER DIN 16 005<br />

SCALE RANGE<br />

63mm and 80mm : -1 ~ 0 to 0 ~ 1000bar<br />

100 and 160mm : -1 ~ 0 to 0~1600bar<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

FILLING LIQUID<br />

Glycerine<br />

Over Range Protection : 130% of Full Scale<br />

WORKING TEMPERATURE<br />

Ambient : -40 ~ 60˚C<br />

Fluid : +100˚C maximum<br />

DEGREE OF PROTECTION<br />

IP65<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

316SS, OPTION-316Ti(1.4571)<br />

and Monel<br />

Threaded entry, radial or back.<br />

ELEMENT<br />

316SS, OPTION-316Ti(1.4571) and Monel<br />

Model : P2534(100mm) & P2526(160mm)<br />

PD02-10<br />

ORDERING INFORMATION<br />

BASE<br />

P258 :<br />

MODEL<br />

LIQUID FILLED INDUSTRIAL <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 63mm<br />

3 : 80mm<br />

4 : 100mm<br />

6 : 160mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

F : Center back Connection, Direct, Only available with diameter 63mm<br />

G: Lower back Connection, Direct<br />

J : Center back Connection, Flush, Cover Mounting Plate, Only available with diameter 63mm<br />

N: Lower back Connection, Flush, Cover Mounting Plate<br />

ACCURACY<br />

3 : 1.0 Per DIN16 005, Not available with diameter 63mm & 80mm<br />

4 : 1.6 Per DIN16 005, Only available with diameter 63mm & 80mm<br />

CONNECTION<br />

C : 1/4”, Only available with diameter 63mm<br />

D : 3/8”, Not available with diameter 63mm<br />

E : 1/2”, Not available with diameter 63mm & 80mm<br />

CONNECTION TYPE<br />

B : PF<br />

C: PT<br />

D: NPT<br />

F : BSPT<br />

G: BSP<br />

Z : Other<br />

UNIT<br />

B : kgf/cm 2<br />

H: bar<br />

L : kgf/cm 2 & Psi<br />

RANGE<br />

P258 4 A 3 E D H 047 3 0<br />

<strong>PRESSURE</strong> MAT’L & DIALS CONNECTION<br />

Refer to Pressure Range Table<br />

3 : 316SS & 2 Colors<br />

4 : 316Ti& 2 Colors<br />

7 : 316SS & 3 Colors, Available<br />

with Compound and Vacuum Gauges<br />

8 : 316Ti & 3 Colors, Available<br />

with Compound and Vacuum Gauges<br />

Z : MONEL<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMBER

P258 : TYPE OF MOUNTING MOUNTING<br />

J<br />

PD02-10

EURO <strong>GAUGE</strong>®<br />

LIQUID FILLED <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

MODEL : P259 SERIES<br />

SERVICE INTENDED<br />

The P259 Series are suitable for corrosive environment.<br />

Typical application include : chemical, petrochemical,<br />

refining, power, marine or food industry The filled liquid absorbs<br />

vibration effect and pulsation pressure.<br />

NOMINAL DIAMETER<br />

63, 100 mm<br />

ACCURACY<br />

Model : P2532(63mm) : 1.6 PER DIN 16 005<br />

Model : P2534(100mm) : 1.0 PER DIN 16 005<br />

SCALE RANGE<br />

63mm : -1~0 to 0~1000bar<br />

100mm : -1~0 to 0~1600bar<br />

WORKING <strong>PRESSURE</strong><br />

Steady : 75% of Full Scale<br />

Over Range Protection : 130% of Full Scale<br />

FILLING LIQUID<br />

Glycerine<br />

WORKING TEMPERATURE<br />

Ambient : -40 ~ 60˚C<br />

Fluid : +60˚C maximum<br />

DEGREE OF PROTECTION<br />

IP54<br />

Standard Features<br />

<strong>PRESSURE</strong> CONNECTION<br />

Cu Alloy 2.0460<br />

Threaded entry, Radial or back.<br />

ELEMENT<br />

Cu Alloy 2.0460<br />

Model : P2534(100mm)<br />

PD02-11<br />

ORDERING INFORMATION<br />

BASE<br />

P259 :<br />

MODEL<br />

LIQUID FILLED <strong>PRESSURE</strong> <strong>GAUGE</strong><br />

NOMINAL DIAMETER<br />

2 : 63mm<br />

4 : 100mm<br />

MOUNTING TYPE (Refer to Mounting type & Dimension)<br />

A : Bottom Connection, Direct<br />

B : Bottom Connection, Surface, Case Mounting Plate<br />

F : Center back Connection, Direct, Only available with diameter 63mm<br />

G: Lower back Connection, Direct, Only available with diameter 100mm<br />

J : Center back Connection, Flush, Cover Mounting Plate, Only available with diameter 63mm<br />

N: Lower back Connection, Flush, Cover Mounting Plate, Only available with diameter 100mm<br />

ACCURACY<br />

3 : 1.0 Per DIN16 005, Not available with diameter 63mm<br />

4 : 1.6 Per DIN16 005, Only available with diameter 63mm<br />

CONNECTION<br />

C : 1/4”, Only available with diameter 63mm<br />

D : 3/8”, Not available with diameter 63mm<br />

E : 1/2”, Not available with diameter 63mm & 80mm<br />

CONNECTION TYPE<br />

B : PF<br />

C: PT<br />

D: NPT<br />

F : BSPT<br />

G: BSP<br />

Z : Other<br />

UNIT<br />

B : kgf/cm 2<br />

H : bar<br />

L : kgf/cm 2 & Psi<br />

RANGE<br />

Refer to Pressure Range Table<br />

DIAL COLOR<br />

1 : 2 Colors<br />

5 : 3 Colors<br />

P259 4 A 3 E D H 047 1 0<br />

OPTIONS<br />

0 : None<br />

1 : Accessories<br />

SAMPLE MODEL NUMBER

P259 : TYPE OF MOUNTING MOUNTING<br />

PD02-11