The Well Built Stair - Shipway Stairs

The Well Built Stair - Shipway Stairs

The Well Built Stair - Shipway Stairs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

STAIRS<br />

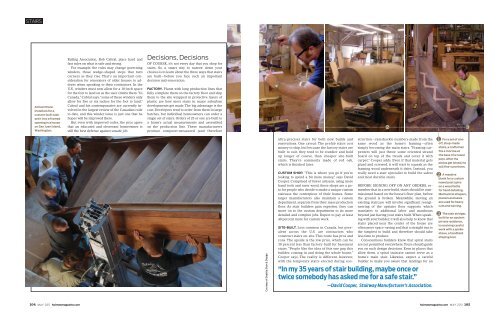

Almost there:<br />

Installers for a<br />

custom-built stair<br />

set it into a framed<br />

opening in a house<br />

on San Juan Island,<br />

Washington.<br />

104 MAY 2011 holmesmagazine.com<br />

Railing Association, Rob Cabral, place hard and<br />

fast rules on what is safe and strong.<br />

For example, the rules may change governing<br />

winders, those wedge-shaped steps that turn<br />

corners as they rise. That’s an important consideration<br />

for renovators of older houses to address<br />

when speaking to their contractors. In the<br />

U.S., winders must now allow for a 10-inch space<br />

for the foot to land on as the user climbs them. “In<br />

Canada,” Cabral says, “some of these winders only<br />

allow for five or six inches for the foot to land.”<br />

Cabral and his contemporaries are currently involved<br />

in the largest review of the Canadian code<br />

to date, and this winder issue is just one that he<br />

hopes will be improved there.<br />

But even with improved codes, the pros agree<br />

that an educated and observant homeowner is<br />

still the best defense against unsafe job.<br />

Decisions, Decisions<br />

OF COURSE, it’s not every day that you shop for<br />

stairs. So, a smart way to narrow down your<br />

choices is to learn about the three ways that stairs<br />

are built—before you face such an important<br />

decision mid-renovation.<br />

FACTORY. Plants with long production lines that<br />

fully complete them on the factory floor and ship<br />

them to the site wrapped in protective layers of<br />

plastic are how most stairs in major suburban<br />

developments get made. <strong>The</strong> big advantage is the<br />

cost. Developers tend to order from them in large<br />

batches, but individual homeowners can order a<br />

single set of stairs. Orders of 25 or one are built to<br />

a home’s actual measurements and assembled<br />

on the production line. <strong>The</strong>se manufacturers<br />

produce computer-measured (and therefore<br />

Courtesy of Seattle <strong>Stair</strong> & Design<br />

1<br />

ultra-precise) stairs for both new builds and<br />

renovations. One caveat: <strong>The</strong> prefab stairs cost<br />

money to ship, but because the factory stairs are<br />

built to suit, they tend to be sturdier and hold<br />

up longer of course, than cheaper site-built<br />

stairs. <strong>The</strong>y’re commonly made of red oak,<br />

which is finished later.<br />

CUSTOM SHOP. “This is where you go if you’re<br />

looking to spend a bit more money,” says David<br />

Cooper. Comprised of fewer artisans, using more<br />

hand tools and rarer wood, these shops are a goto<br />

for people who decide to make a unique custom<br />

staircase the centerpiece of their homes. Some<br />

larger manufacturers also maintain a custom<br />

department, separate from their mass production<br />

floor. As stair builders gain expertise, they can<br />

move on to the custom department to do more<br />

detailed and complex jobs. Expect to pay at least<br />

40 percent more for custom work.<br />

SITE-BUILT. Less common in Canada, but prevalent<br />

across the U.S. are contractors who<br />

construct stairs on-site. This route has pros and<br />

cons. <strong>The</strong> upside is the low price, which can be<br />

30 percent less than factory-built for basement<br />

stairs. “People like the idea of this one guy, this<br />

builder, coming in and doing the whole house,”<br />

Cooper says. <strong>The</strong> reality is different, however,<br />

with the temporary stairs erected during con-<br />

“In my 35 years of stair building, maybe once or<br />

twice somebody has asked me for a safe stair.”<br />

2 3<br />

struction—ramshackle numbers made from the<br />

same wood as the home’s framing—often<br />

simply becoming the main stairs. “Framing carpenters<br />

will just throw some oriented strand<br />

board on top of the treads and cover it with<br />

carpet,” Cooper adds. Even if that material gets<br />

glued and screwed, it will start to squeak as the<br />

framing wood underneath it dries. Instead, you<br />

really need a stair specialist to build the safest<br />

and most durable stairs.<br />

BEFORE SIGNING OFF ON ANY ORDERS, remember<br />

that in a new build, stairs should be commissioned<br />

based on the house’s floor plan, before<br />

the ground is broken. Meanwhile, moving an<br />

existing staircase will involve significant reengineering<br />

of the upstairs floor supports, which<br />

translates to additional labor and manhours<br />

beyond just having your stairs built. When speaking<br />

with your builder, it will also help to know that<br />

stairs placed near the center of the house are<br />

often more space-saving and that a straight run is<br />

the simplest to build and therefore should take<br />

less time to produce.<br />

Conscientious builders know that spiral stairs<br />

are not permitted everywhere. Yours should guide<br />

you on such design decisions. Even in places that<br />

allow them, a spiral staircase cannot serve as a<br />

home’s main stair. Likewise, expect a careful<br />

builder to make you aware that landings for an<br />

—David Cooper, <strong>Stair</strong>way Manufacturer’s Association.<br />

1<br />

For a set of oneoff,<br />

shop-made<br />

stairs, a craftsman<br />

fits a mortise at<br />

the base of a newel<br />

post. After the<br />

pieces get joined, he<br />

will fine-tune them.<br />

2<br />

A massive<br />

blank for a custom<br />

newel post spins<br />

on a wood lathe<br />

for hand detailing.<br />

Mechanical shapers,<br />

planers and saws<br />

are used for heavy<br />

cuts and carving.<br />

3<br />

<strong>The</strong> stair stringer,<br />

built for an opulent<br />

private residence,<br />

is receiving careful<br />

work with a spokeshave,<br />

a handheld<br />

shaping tool.<br />

holmesmagazine.com MAY 2011 105