Decorative Weaving Techniques - International Textiles Archive ...

Decorative Weaving Techniques - International Textiles Archive ...

Decorative Weaving Techniques - International Textiles Archive ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

28<br />

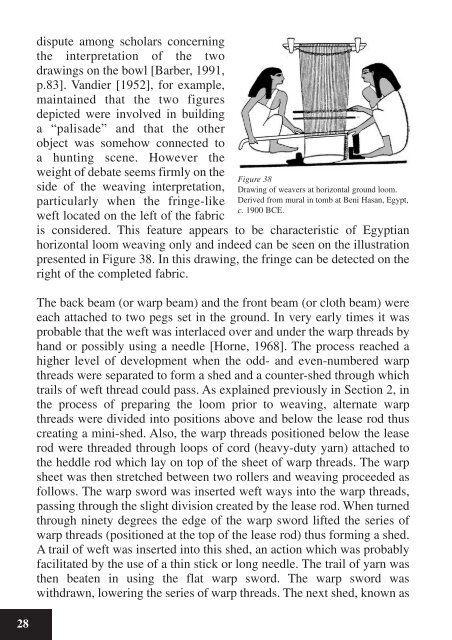

dispute among scholars concerning<br />

the interpretation of the two<br />

drawings on the bowl [Barber, 1991,<br />

p.83]. Vandier [1952], for example,<br />

maintained that the two figures<br />

depicted were involved in building<br />

a “palisade” and that the other<br />

object was somehow connected to<br />

a hunting scene. However the<br />

weight of debate seems firmly on the<br />

side of the weaving interpretation,<br />

particularly when the fringe-like<br />

weft located on the left of the fabric<br />

Figure 38<br />

Drawing of weavers at horizontal ground loom.<br />

Derived from mural in tomb at Beni Hasan, Egypt,<br />

c. 1900 BCE.<br />

is considered. This feature appears to be characteristic of Egyptian<br />

horizontal loom weaving only and indeed can be seen on the illustration<br />

presented in Figure 38. In this drawing, the fringe can be detected on the<br />

right of the completed fabric.<br />

The back beam (or warp beam) and the front beam (or cloth beam) were<br />

each attached to two pegs set in the ground. In very early times it was<br />

probable that the weft was interlaced over and under the warp threads by<br />

hand or possibly using a needle [Horne, 1968]. The process reached a<br />

higher level of development when the odd- and even-numbered warp<br />

threads were separated to form a shed and a counter-shed through which<br />

trails of weft thread could pass. As explained previously in Section 2, in<br />

the process of preparing the loom prior to weaving, alternate warp<br />

threads were divided into positions above and below the lease rod thus<br />

creating a mini-shed. Also, the warp threads positioned below the lease<br />

rod were threaded through loops of cord (heavy-duty yarn) attached to<br />

the heddle rod which lay on top of the sheet of warp threads. The warp<br />

sheet was then stretched between two rollers and weaving proceeded as<br />

follows. The warp sword was inserted weft ways into the warp threads,<br />

passing through the slight division created by the lease rod. When turned<br />

through ninety degrees the edge of the warp sword lifted the series of<br />

warp threads (positioned at the top of the lease rod) thus forming a shed.<br />

A trail of weft was inserted into this shed, an action which was probably<br />

facilitated by the use of a thin stick or long needle. The trail of yarn was<br />

then beaten in using the flat warp sword. The warp sword was<br />

withdrawn, lowering the series of warp threads. The next shed, known as