Chapter 12 Large-scale and Industrial Utilisation - Anamed

Chapter 12 Large-scale and Industrial Utilisation - Anamed

Chapter 12 Large-scale and Industrial Utilisation - Anamed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

less brittle product than with water hyacinth alone, see Shah <strong>and</strong> Bhattacharya<br />

(1983). The briquetting takes place because the compression of the screw<br />

together with the heating coils raise the temperature to 250 degrees centigrade. It<br />

is believed that the high temperature softens the lignin, which behaves as a<br />

waterproof glue. They use an extruding machine that produces 2 briquettes per<br />

minute, each 50cm long <strong>and</strong> 0.5kg in weight. The heat content of the briquettes<br />

is about 85% that of wood charcoal The energy output of each briquette exceeds<br />

the energy used in its production by a<br />

factor of about ten.<br />

In Thail<strong>and</strong> also briquettes<br />

are made which are a mixture of<br />

ground lignite, dried water<br />

hyacinth <strong>and</strong> binder in the ratio<br />

6:3:1. The binder is 4% glue,<br />

3% resin <strong>and</strong> 3% a synthetic<br />

compound made from tapioca.<br />

Such briquettes, which are very<br />

strong, have four times more<br />

heat than wood charcoal <strong>and</strong><br />

cost 30% less than wood<br />

charcoal.<br />

In Kenya, briquettes are<br />

produced from coffee husks. It<br />

is possible that such briquettes<br />

could be produced in all coffee<br />

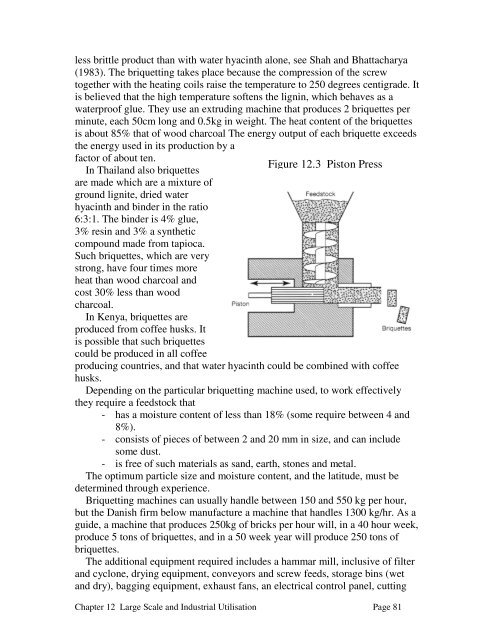

Figure <strong>12</strong>.3 Piston Press<br />

producing countries, <strong>and</strong> that water hyacinth could be combined with coffee<br />

husks.<br />

Depending on the particular briquetting machine used, to work effectively<br />

they require a feedstock that<br />

- has a moisture content of less than 18% (some require between 4 <strong>and</strong><br />

8%).<br />

- consists of pieces of between 2 <strong>and</strong> 20 mm in size, <strong>and</strong> can include<br />

some dust.<br />

- is free of such materials as s<strong>and</strong>, earth, stones <strong>and</strong> metal.<br />

The optimum particle size <strong>and</strong> moisture content, <strong>and</strong> the latitude, must be<br />

determined through experience.<br />

Briquetting machines can usually h<strong>and</strong>le between 150 <strong>and</strong> 550 kg per hour,<br />

but the Danish firm below manufacture a machine that h<strong>and</strong>les 1300 kg/hr. As a<br />

guide, a machine that produces 250kg of bricks per hour will, in a 40 hour week,<br />

produce 5 tons of briquettes, <strong>and</strong> in a 50 week year will produce 250 tons of<br />

briquettes.<br />

The additional equipment required includes a hammar mill, inclusive of filter<br />

<strong>and</strong> cyclone, drying equipment, conveyors <strong>and</strong> screw feeds, storage bins (wet<br />

<strong>and</strong> dry), bagging equipment, exhaust fans, an electrical control panel, cutting<br />

<strong>Chapter</strong> <strong>12</strong> <strong>Large</strong> Scale <strong>and</strong> <strong>Industrial</strong> <strong>Utilisation</strong> Page 81