Nord Catalogue - Nottingham Electrical Transmissions

Nord Catalogue - Nottingham Electrical Transmissions

Nord Catalogue - Nottingham Electrical Transmissions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SELECTION PROCEDURES<br />

Criteria for selection of the gearboxes are:<br />

1) mechanical power - service factor shown in the<br />

tables in catalog<br />

2) thermal power limit - depending on<br />

a) mounting position e.g. V5/V6/V (oil quantity)<br />

b) the ratio i 3h<br />

(thermal load)<br />

Please contact application engineering for gearbox types marked * .<br />

Higher powers possible with short term operation. For continuous operation<br />

special features (optimal oil-level, oil-cooler etc.) may be required, please<br />

consult factory.<br />

Each application requires either the calculation or the measurement of the<br />

required motor power. Base the motor selection on the above power<br />

requirement. Intermittent shock loading should not be considered for motor<br />

power determination.<br />

On the other hand, it is important to consider the type of loading when<br />

selecting the gearbox size. The service factor fB can be determined by taking<br />

into account the factor of inertia maf as well as cycles/ hour and the operating<br />

time.<br />

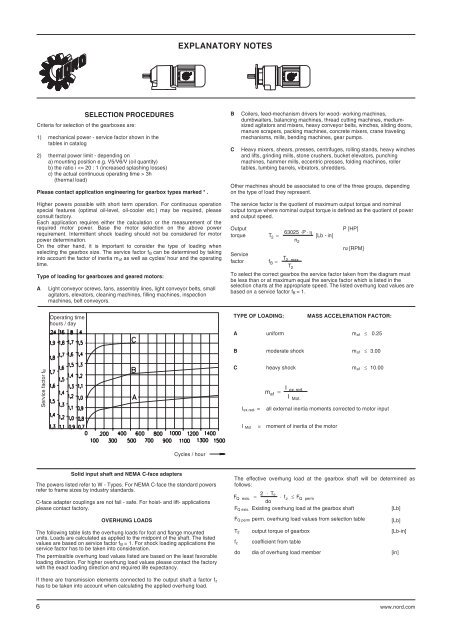

Type of loading for gearboxes and geared motors:<br />

A Light conveyor screws, fans, assembly lines, light conveyor belts, small<br />

agitators, elevators, cleaning machines, filling machines, inspection<br />

machines, belt conveyors.<br />

Service factor fB<br />

Operating time<br />

hours / day<br />

Solid input shaft and NEMA C-face adapters<br />

The powers listed refer to W - Types. For NEMA C-face the standard powers<br />

refer to frame sizes by industry standards.<br />

C-face adapter couplings are not fail - safe. For hoist- and lift- applications<br />

please contact factory.<br />

OVERHUNG LOADS<br />

The following table lists the overhung loads for foot and flange mounted<br />

units. Loads are calculated as applied to the midpoint of the shaft. The listed<br />

values are based on service factor fB = 1. For shock loading applications the<br />

service factor has to be taken into consideration.<br />

The permissible overhung load values listed are based on the least favorable<br />

loading direction. For higher overhung load values please contact the factory<br />

with the exact loading direction and required life expectancy.<br />

If there are transmission elements connected to the output shaft a factor fz<br />

has to be taken into account when calculating the applied overhung load.<br />

EXPLANATORY NOTES<br />

Cycles / hour<br />

B Coilers, feed-mechanism drivers for wood- working machines,<br />

dumbwaiters, balancing machines, thread cutting machines, mediumsized<br />

agitators and mixers, heavy conveyor belts, winches, sliding doors,<br />

manure scrapers, packing machines, concrete mixers, crane traveling<br />

mechanisms, mills, bending machines, gear pumps.<br />

C Heavy mixers, shears, presses, centrifuges, rolling stands, heavy winches<br />

and lifts, grinding mills, stone crushers, bucket elevators, punching<br />

machines, hammer mills, eccentric presses, folding machines, roller<br />

tables, tumbing barrels, vibrators, shredders.<br />

Other machines should be associated to one of the three groups, depending<br />

on the type of load they represent.<br />

The service factor is the quotient of maximum output torque and nominal<br />

output torque where nominal output torque is defined as the quotient of power<br />

and output speed.<br />

Output<br />

torque T2<br />

<br />

63025 P n2<br />

[Lb - in]<br />

P [HP]<br />

n2 [RPM]<br />

Service<br />

factor fB<br />

<br />

T2<br />

max<br />

T2<br />

To select the correct gearbox the service factor taken from the diagram must<br />

be less than or at maximum equal the service factor which is listed in the<br />

selection charts at the appropriate speed. The listed overhung load values are<br />

based on a service factor fB =1.<br />

TYPE OF LOADING: MASS ACCELERATION FACTOR:<br />

A uniform maf 0.25<br />

B moderate shock maf 3.00<br />

C heavy shock maf 10.00<br />

maf<br />

<br />

I ex.red.<br />

I Mot.<br />

Iex.red. = all external inertia moments corrected to motor input<br />

I Mot = moment of inertia of the motor<br />

The effective overhung load at the gearbox shaft will be determined as<br />

follows:<br />

FQ<br />

exis. <br />

2 T2<br />

do<br />

fz FQperm<br />

FQ exis. Existing overhung load at the gearbox shaft [Lb]<br />

FQ perm perm. overhung load values from selection table [Lb]<br />

T2 output torque of gearbox [Lb-in]<br />

fz coefficient from table<br />

do dia of overhung load member [in]<br />

6 www.nord.com