Emissions in Remission - Albemarle Corporation

Emissions in Remission - Albemarle Corporation

Emissions in Remission - Albemarle Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Increas<strong>in</strong>g middle distillates yields <strong>in</strong><br />

FCC with MFCC catalysts<br />

Worldwide demand for diesel cont<strong>in</strong>ues to grow, especially <strong>in</strong> Western Europe, Asia and Lat<strong>in</strong> America. A<br />

number of factors are driv<strong>in</strong>g this <strong>in</strong>crease: the superior economy and efficiency of diesel eng<strong>in</strong>es; recent<br />

advances <strong>in</strong> combustion systems such as the <strong>in</strong>troduction of “Common-Rail” technology; and improvements <strong>in</strong><br />

emissions devices <strong>in</strong>clud<strong>in</strong>g filters for the removal of micro-particulates and NOx reduction systems.<br />

In some regions, the grow<strong>in</strong>g use of light vehicles powered by<br />

Otto eng<strong>in</strong>es has <strong>in</strong>creased demand for alternative fuels such<br />

as natural gas, LPG and ethanol, contribut<strong>in</strong>g to a steady<br />

decl<strong>in</strong>e <strong>in</strong> demand for gasol<strong>in</strong>e <strong>in</strong> those areas.<br />

These developments have affected the operation of FCC units,<br />

lead<strong>in</strong>g an <strong>in</strong>creas<strong>in</strong>g number of ref<strong>in</strong>ers to look for routes for<br />

maximiz<strong>in</strong>g middle distillates, with a simultaneous reduction<br />

<strong>in</strong> the yield of cracked naphtha.<br />

Catalyst architecture for middle distillates<br />

maximization<br />

To meet the needs of this grow<strong>in</strong>g niche market, FCC S.A. has<br />

developed the (Mild Fluid Catalytic Crack<strong>in</strong>g) MFCC series,<br />

adapted to this new profile of liquid fuels demand. MFCC<br />

<strong>in</strong>creases the volume and quality of middle distillate (Light<br />

Cycle Oil, or LCO) produced while simultaneously reduc<strong>in</strong>g<br />

the bottoms yield.<br />

In the development of the MFCC family, special attention was<br />

given to the reaction network of generation and subsequent<br />

conversion (overcrack<strong>in</strong>g) of the molecules <strong>in</strong> the middle<br />

distillates boil<strong>in</strong>g range. The aliphatic compounds (olef<strong>in</strong>s and<br />

paraff<strong>in</strong>s) formed <strong>in</strong> this cut are easily converted to lighter<br />

products <strong>in</strong> the naphtha range. Therefore, operation at mild<br />

reaction temperatures is important <strong>in</strong> order to ma<strong>in</strong>ta<strong>in</strong> the<br />

target cutt<strong>in</strong>g range. The formation of aromatics is also<br />

reduced through the attenuation of hydrogen transfer<br />

reactions.<br />

Commercial FCC performance with MFCC<br />

catalysts<br />

A first <strong>in</strong>dustrial trial of this product family took place <strong>in</strong> a<br />

UOP HTR FCC unit operated by PETROBRAS/ Brazil, utiliz<strong>in</strong>g<br />

MFCC-1 catalyst.<br />

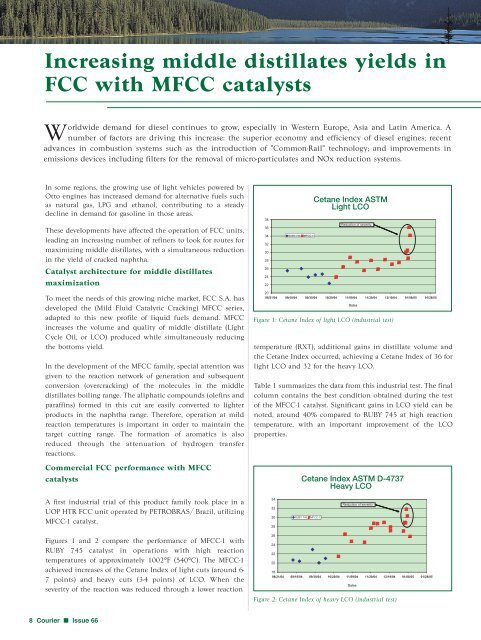

Figures 1 and 2 compare the performance of MFCC-1 with<br />

RUBY 745 catalyst <strong>in</strong> operations with high reaction<br />

temperatures of approximately 1002°F (540°C). The MFCC-1<br />

achieved <strong>in</strong>creases of the Cetane Index of light cuts (around 6-<br />

7 po<strong>in</strong>ts) and heavy cuts (3-4 po<strong>in</strong>ts) of LCO. When the<br />

severity of the reaction was reduced through a lower reaction<br />

8 Courier ■ Issue 66<br />

38<br />

36<br />

34<br />

32<br />

30<br />

28<br />

26<br />

24<br />

22<br />

Figure 1: Cetane Index of light LCO (<strong>in</strong>dustrial test)<br />

temperature (RXT), additional ga<strong>in</strong>s <strong>in</strong> distillate volume and<br />

the Cetane Index occurred, achiev<strong>in</strong>g a Cetane Index of 36 for<br />

light LCO and 32 for the heavy LCO.<br />

Table 1 summarizes the data from this <strong>in</strong>dustrial test. The f<strong>in</strong>al<br />

column conta<strong>in</strong>s the best condition obta<strong>in</strong>ed dur<strong>in</strong>g the test<br />

of the MFCC-1 catalyst. Significant ga<strong>in</strong>s <strong>in</strong> LCO yield can be<br />

noted, around 40% compared to RUBY 745 at high reaction<br />

temperature, with an important improvement of the LCO<br />

properties.<br />

34<br />

32<br />

30<br />

28<br />

26<br />

24<br />

22<br />

20<br />

RUBY-745 MFCC-1<br />

Cetane Index ASTM D-4737<br />

Heavy LCO<br />

RUBY-745 MFCC-1<br />

Cetane Index ASTM<br />

Light LCO<br />

Reduction of severity<br />

20<br />

08/21/04 09/10/04 09/30/04 10/20/04 11/09/04 11/29/04 12/19/04 01/08/05 01/28/05<br />

Dates<br />

Reduction of severity<br />

18<br />

08/21/04 09/10/04 09/30/04 10/20/04 11/09/04 11/29/04 12/19/04 01/08/05 01/28/05<br />

Dates<br />

Figure 2: Cetane Index of heavy LCO (<strong>in</strong>dustrial test)