Rheological Additives in Cosmetics - Elementis Specialties

Rheological Additives in Cosmetics - Elementis Specialties

Rheological Additives in Cosmetics - Elementis Specialties

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

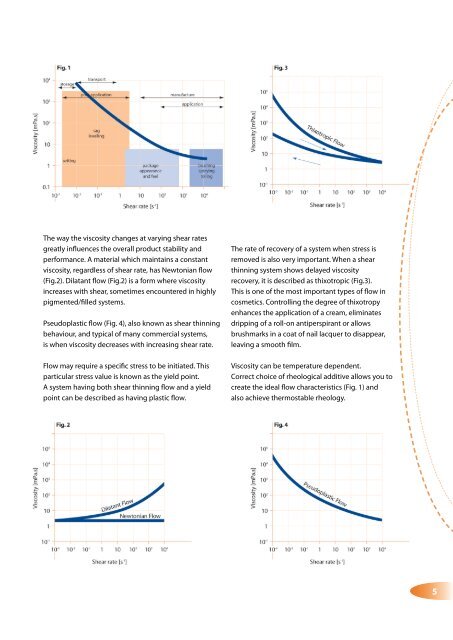

The way the viscosity changes at vary<strong>in</strong>g shear rates<br />

greatly <strong>in</strong>fluences the overall product stability and<br />

performance. A material which ma<strong>in</strong>ta<strong>in</strong>s a constant<br />

viscosity, regardless of shear rate, has Newtonian flow<br />

(Fig.2). Dilatant flow (Fig.2) is a form where viscosity<br />

<strong>in</strong>creases with shear, sometimes encountered <strong>in</strong> highly<br />

pigmented/filled systems.<br />

Pseudoplastic flow (Fig. 4), also known as shear th<strong>in</strong>n<strong>in</strong>g<br />

behaviour, and typical of many commercial systems,<br />

is when viscosity decreases with <strong>in</strong>creas<strong>in</strong>g shear rate.<br />

Flow may require a specific stress to be <strong>in</strong>itiated. This<br />

particular stress value is known as the yield po<strong>in</strong>t.<br />

A system hav<strong>in</strong>g both shear th<strong>in</strong>n<strong>in</strong>g flow and a yield<br />

po<strong>in</strong>t can be described as hav<strong>in</strong>g plastic flow.<br />

The rate of recovery of a system when stress is<br />

removed is also very important. When a shear<br />

th<strong>in</strong>n<strong>in</strong>g system shows delayed viscosity<br />

recovery, it is described as thixotropic (Fig.3).<br />

This is one of the most important types of flow <strong>in</strong><br />

cosmetics. Controll<strong>in</strong>g the degree of thixotropy<br />

enhances the application of a cream, elim<strong>in</strong>ates<br />

dripp<strong>in</strong>g of a roll-on antiperspirant or allows<br />

brushmarks <strong>in</strong> a coat of nail lacquer to disappear,<br />

leav<strong>in</strong>g a smooth film.<br />

Viscosity can be temperature dependent.<br />

Correct choice of rheological additive allows you to<br />

create the ideal flow characteristics (Fig. 1) and<br />

also achieve thermostable rheology.<br />

5