here we are SANILINE G

here we are SANILINE G

here we are SANILINE G

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

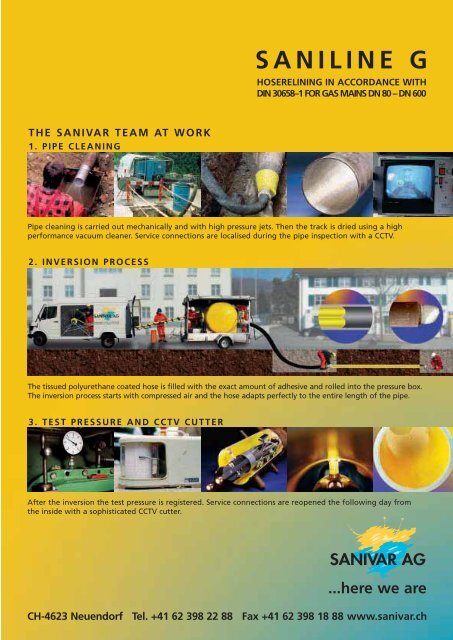

THE SANIVAR TEAM AT WORK<br />

1. PIPE CLEANING<br />

Pipe cleaning is carried out mechanically and with high pressure jets. Then the track is dried using a high<br />

performance vacuum cleaner. Service connections <strong>are</strong> localised during the pipe inspection with a CCTV.<br />

2. INVERSION PROCESS<br />

The tissued polyurethane coated hose is filled with the exact amount of adhesive and rolled into the pressure box.<br />

The inversion process starts with compressed air and the hose adapts perfectly to the entire length of the pipe.<br />

3. TEST PRESSURE AND CCTV CUTTER<br />

<strong>SANILINE</strong> G<br />

HOSERELINING IN ACCORDANCE WITH<br />

DIN 30658–1 FOR GAS MAINS DN 80 – DN 600<br />

After the inversion the test pressure is registered. Service connections <strong>are</strong> reopened the following day from<br />

the inside with a sophisticated CCTV cutter.<br />

...<strong>here</strong> <strong>we</strong> <strong>are</strong><br />

CH-4623 Neuendorf Tel. +41 62 398 22 88 Fax +41 62 398 18 88 www.sanivar.ch