Standardization adds value to FPSO topsides - Alliance Wood ...

Standardization adds value to FPSO topsides - Alliance Wood ...

Standardization adds value to FPSO topsides - Alliance Wood ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

production operations<br />

field-proven and can give a basis for future<br />

designs.<br />

Safety – Standardized design modules<br />

would meet applicable safety standards and<br />

industry design practices, and can be tailored<br />

<strong>to</strong> meet opera<strong>to</strong>r requirements.<br />

Experience contributes<br />

<strong>to</strong> standardization<br />

The <strong>FPSO</strong> is complex. It requires many<br />

disciplines <strong>to</strong> engineer and design its <strong>to</strong>pside<br />

facilities. Based on experience and<br />

using a design library, each discipline can<br />

contribute specific standardized approaches<br />

<strong>to</strong> accelerate the project and <strong>to</strong> offer the<br />

most benefits.<br />

Layout and piping design: Layout of the<br />

<strong>to</strong>pside facilities is driven by the sequential<br />

placement of the processing systems<br />

coupled with the safety policies imposed<br />

on production facilities. In addition, no<br />

single layout works for all combinations of<br />

processing facilities, vessel configurations,<br />

and me<strong>to</strong>cean conditions. There are, however,<br />

common rules influencing the design<br />

that can be used <strong>to</strong> develop standardized<br />

configurations for most scenarios. The<br />

standardized layout generally facilitates<br />

integration of all disciplines and enables<br />

them <strong>to</strong> standardize as well.<br />

The key <strong>to</strong> an optimal layout is modularization<br />

by process or utility system. Each<br />

major system is treated as a stand-alone<br />

system and as a modularized component<br />

of the entire facility. This concept will be<br />

the same regardless of facility type or capacity.<br />

Differences in equipment capacity<br />

or pressure ratings might alter the size of<br />

the modules, but will have minimal impact<br />

on layout.<br />

Safety is most important in the <strong>to</strong>psides<br />

layout. Process modules are placed away<br />

from the quarters and control buildings.<br />

Only benign or non-hazardous equipment<br />

is located near the commonly occupied safe<br />

areas. This policy sets the <strong>to</strong>ne for the overall<br />

configuration. More hazardous systems<br />

like gas compressors, production modules,<br />

and vents or flares usually are placed at one<br />

end of the facility. The remaining modules<br />

are placed in a sequential order following<br />

the steps of the treating process, which<br />

generally coincides with a decreasing level<br />

of risk.<br />

The standardized layout uses a central<br />

corridor with modules on either side and<br />

pipe racks running from bow <strong>to</strong> stern. The<br />

piping interfaces between modules should<br />

be kept <strong>to</strong> a minimum. This configuration<br />

minimizes the impact of relative motion<br />

caused by wave action and resulting hog<br />

and sag of mid-ship bending. It also fosters<br />

personnel safety by allowing for access,<br />

egress, and the materials handling necessary<br />

for operation and maintenance.<br />

Equipment-specific features also are incorporated<br />

in<strong>to</strong> the standardized layout.<br />

Motion-sensitive separa<strong>to</strong>rs like stabilizers<br />

and contac<strong>to</strong>rs typically are located near the<br />

ship’s center of motion <strong>to</strong> reduce the effects<br />

of motion on level control and the separation<br />

process. High-speed rotating equipment<br />

such as turbine-driven compressors and<br />

genera<strong>to</strong>rs are aligned along the length of<br />

the <strong>FPSO</strong>. Large reciprocating compressors<br />

are placed with cylinders transverse <strong>to</strong> the<br />

ship, using the hull’s bulkheads <strong>to</strong> resist the<br />

compressor’s unbalanced forces and moments.<br />

Another option for module configuration<br />

is <strong>to</strong> integrate the pipe rack in<strong>to</strong> the module<br />

structure. This can reduce cost and<br />

time by eliminating the stand-alone pipe<br />

rack and reducing the number of piping<br />

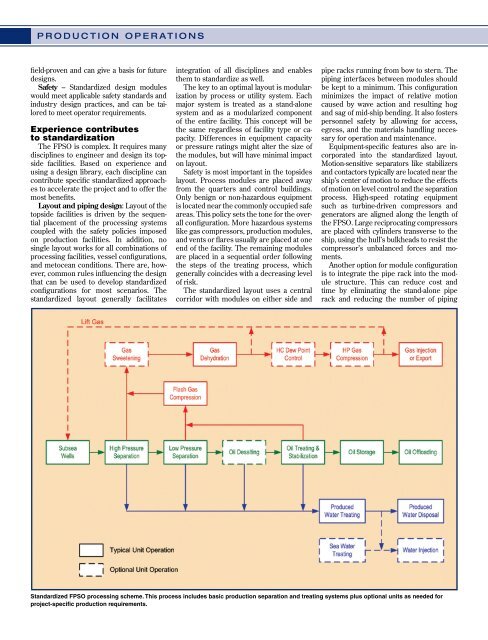

Standardized <strong>FPSO</strong> processing scheme. This process includes basic production separation and treating systems plus optional units as needed for<br />

project-specific production requirements.