Conesys - Aero-Electric Connector, Inc.

Conesys - Aero-Electric Connector, Inc.

Conesys - Aero-Electric Connector, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Performance Specifications<br />

Operating Temperature Range<br />

Classes KS and LS: -55°C to +200°C (-67°F to +392°F)<br />

Classes KT and W: -55°C to +175°C (-67°F to +347°F)<br />

Class L: -55°C to +200°C (-67°F to +392°F)<br />

Class A*: -55°C to +200°C (-67°F to +392°F)<br />

Material and Finish Data (Class)<br />

KT– carbon steel shell, olive drab cadmium, firewall<br />

KS – stainless steel shell, passivated, firewall<br />

L – aluminum shell, electroless nickel finish<br />

LS – stainless steel shell, passivated<br />

W–aluminum shell, olive drab cadmium over nickel base<br />

A* – aluminum shell, black anodized finish<br />

Corrosion Resistance<br />

Classes KS and LS withstand 1,000-hour salt spray.<br />

Class KT withstands 96-hour salt spray.<br />

Class L withstands 96-hour salt spray.<br />

Class W withstands 1,000-hour salt spray.<br />

Environmental Seal<br />

Wired, mated connectors with specified accessories<br />

attached, shall meet the altitude-immersion test specified in<br />

MIL-DTL-5015.<br />

Durability<br />

Minimum of 100 mating cycles<br />

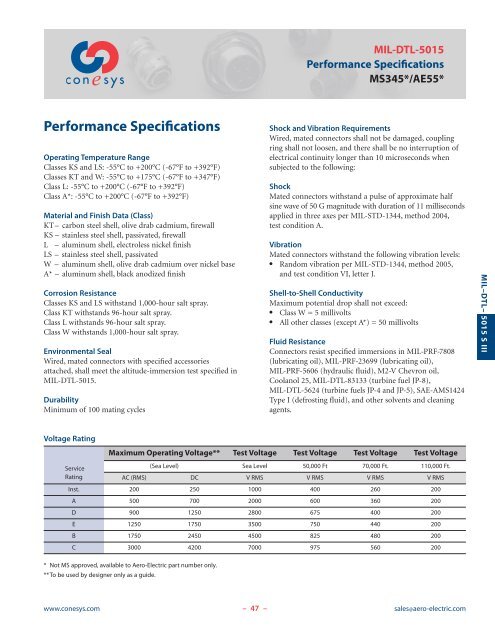

Voltage Rating<br />

Service<br />

Rating<br />

* Not MS approved, available to <strong>Aero</strong>-<strong>Electric</strong> part number only.<br />

**To be used by designer only as a guide.<br />

MIL-DTL-5015<br />

Performance Specifications<br />

MS345*/AE55*<br />

Shock and Vibration Requirements<br />

Wired, mated connectors shall not be damaged, coupling<br />

ring shall not loosen, and there shall be no interruption of<br />

electrical continuity longer than 10 microseconds when<br />

subjected to the following:<br />

Shock<br />

Mated connectors withstand a pulse of approximate half<br />

sine wave of 50 G magnitude with duration of 11 milliseconds<br />

applied in three axes per MIL-STD-1344, method 2004,<br />

test condition A.<br />

Vibration<br />

Mated connectors withstand the following vibration levels:<br />

● Random vibration per MIL-STD-1344, method 2005,<br />

and test condition VI, letter J.<br />

Shell-to-Shell Conductivity<br />

Maximum potential drop shall not exceed:<br />

● Class W = 5 millivolts<br />

● All other classes (except A*) = 50 millivolts<br />

Fluid Resistance<br />

<strong>Connector</strong>s resist specified immersions in MIL-PRF-7808<br />

(lubricating oil), MIL-PRF-23699 (lubricating oil),<br />

MIL-PRF-5606 (hydraulic fluid), M2-V Chevron oil,<br />

Coolanol 25, MIL-DTL-83133 (turbine fuel JP-8),<br />

MIL-DTL-5624 (turbine fuels JP-4 and JP-5), SAE-AMS1424<br />

Type I (defrosting fluid), and other solvents and cleaning<br />

agents.<br />

Maximum Operating Voltage** Test Voltage Test Voltage Test Voltage Test Voltage<br />

(Sea Level) Sea Level 50,000 Ft 70,000 Ft. 110,000 Ft.<br />

AC (RMS) DC V RMS V RMS V RMS V RMS<br />

Inst. 200 250 1000 400 260 200<br />

A 500 700 2000 600 360 200<br />

D 900 1250 2800 675 400 200<br />

E 1250 1750 3500 750 440 200<br />

B 1750 2450 4500 825 480 200<br />

C 3000 4200 7000 975 560 200<br />

www.conesys.com – 47 –<br />

sales@aero-electric.com<br />

MIL–DTL– 5015 S III