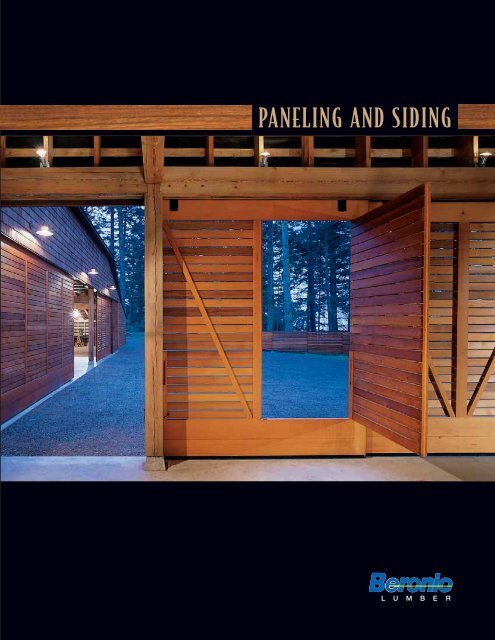

Paneling and Siding Catalog - Beronio Lumber

Paneling and Siding Catalog - Beronio Lumber

Paneling and Siding Catalog - Beronio Lumber

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PANELING AND SIDING

Founded in 1911 by Antone V. <strong>Beronio</strong>, <strong>Beronio</strong> <strong>Lumber</strong> has supplied fine<br />

wood products to architects <strong>and</strong> builders for over ninety years. From its<br />

original yard on Powell <strong>and</strong> Beach Streets on San Francisco’s bustling<br />

waterfront, <strong>Beronio</strong> sold lumber, millwork <strong>and</strong> mouldings to the<br />

contractors busy rebuilding the city after the devastating earthquake <strong>and</strong><br />

fire of 1906. It was these proud craftsmen who created the rich<br />

architectural heritage for which San Francisco is famous today.<br />

From the beginning, <strong>Beronio</strong> <strong>Lumber</strong> has offered high quality wood<br />

paneling <strong>and</strong> siding. Over the years we’ve amassed a wide assortment of<br />

patterns <strong>and</strong> profiles. This catalog includes snapshots of some of the<br />

many patterns <strong>and</strong> profiles presently in inventory. While we’ve tried our<br />

best to show representative pieces, it’s impossible for just one piece to<br />

convey the full range <strong>and</strong> depth of the natural characteristics found in a<br />

particular wood species or lumber grade. Naturally, it’s best to come <strong>and</strong><br />

see for yourself which species <strong>and</strong> grade best meet your needs.<br />

Can’t find something in this catalog that meets your needs? No<br />

problem. We look forward to working with you to produce a custom<br />

pattern or profile.<br />

All patterns are subject to change without notice. Please check with<br />

<strong>Beronio</strong> <strong>Lumber</strong> before making final choices.

4<br />

PANELING AND WAINSCOTING<br />

Wood paneling enhances any décor. Whether it’s smooth, textured,<br />

patterned, stained, tinted, waxed or natural, real wood has a unique look<br />

<strong>and</strong> radiates a warmth unmatched by other interior finishes. With so many<br />

options to choose from, how do you decide? We recommend Rob Thallon’s<br />

Graphic Guide to Interior Details published by The Taunton Press as a good<br />

introduction to millwork in general <strong>and</strong> to paneling in particular. Or, you<br />

might try the Western Wood Products Association’s idea booklet Real<br />

Wood Interiors—A Design Workbook. A great source for specific<br />

installation details is the book <strong>and</strong> companion video Trim Carpentry<br />

Techniques by Craig Savage, also from The Taunton Press. These books<br />

<strong>and</strong> more are available at our Marin Street store.<br />

Naturally, most wainscot patterns serve equally well when used as wall or<br />

ceiling paneling.

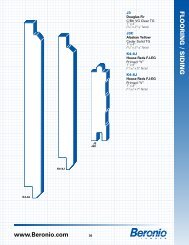

J3 1 x 4<br />

Douglas Fir<br />

C/Btr VG Clear TG<br />

3/4” Thick<br />

3-1/8” Face<br />

J4-C 3/8 x 4<br />

Cherry Bead<br />

5/16” Thick<br />

3-1/8” Face<br />

PANELING AND WAINSCOTING<br />

J3-C 1 x 4<br />

Alaskan Yellow<br />

C Solid TG VG<br />

3/4” Thick<br />

3-1/8” Face<br />

J4-C 3/8 x 4<br />

Cherry<br />

V Reversible TG<br />

5/16” Thick<br />

3-1/8” Face<br />

5

6<br />

J4-G 3/8 x 4<br />

Genuine Mahogany<br />

Bead<br />

5/16” Thick<br />

3-1/8” Face<br />

J4-M 3/8 x 4<br />

Maple TG<br />

Bead Side<br />

5/16” Thick<br />

3-1/8” Face<br />

PANELING AND WAINSCOTING<br />

J4-G 3/8 x 4<br />

Genuine Mahogany<br />

V Reversible TG<br />

5/16” Thick<br />

3-1/8” Face<br />

J4-M 3/8 x 4<br />

Maple<br />

V Reversible TG<br />

5/16” Thick<br />

3-1/8” Face

J4-R 3/8 x 4<br />

Red Oak<br />

Flat Sawn Bead<br />

5/16” Thick<br />

3-1/8” Face<br />

J5 1 x 4<br />

Douglas Fir<br />

C Solid VG TG<br />

Double Bead Back<br />

9/16” Thick<br />

3-1/8” Face<br />

PANELING AND WAINSCOTING<br />

J4-R 3/8 x 4<br />

Red Oak<br />

V Reversible TG<br />

5/16” Thick<br />

3-1/8” Face<br />

J5 1 x 4<br />

Douglas Fir<br />

Single Bead Face<br />

9/16” Thick<br />

3-1/8” Face<br />

7

8<br />

J5J 1 x 4<br />

House White<br />

TG Bead<br />

9/16” Thick<br />

3-1/8” Face<br />

J6C 1 x 4<br />

Red Cedar Clear Heart<br />

VG TG Beaded<br />

5/8” Thick<br />

3-1/8” Face<br />

PANELING AND WAINSCOTING<br />

J5J 1 x 4<br />

House White<br />

TG V-Side<br />

9/16” Thick<br />

3-1/8” Face<br />

J6C 1 x 4<br />

Red Cedar Clear<br />

Heart TG V-Side<br />

5/8” Thick<br />

3-1/8” Face

J6J 1 x 4<br />

FJ Pine<br />

TG Bead<br />

5/8” Thick<br />

3-1/4” Face<br />

PANELING AND WAINSCOTING<br />

J6K 1 x 4<br />

Pine/Spruce Appearance<br />

Knotty TG Beaded<br />

11/16” Thick<br />

3-1/8” Face<br />

J6J 1 x 4<br />

FJ Pine<br />

TG Bead V-Side<br />

5/8” Thick<br />

3-1/4” Face<br />

J6K 1 x 4<br />

Pine/Spruce<br />

TG Bead V-Side<br />

11/16” Thick<br />

3-1/8” Face<br />

9

10<br />

J15-DF 1/2 x 4<br />

Douglas Fir<br />

B VG Resawn TG<br />

1/2” Thick<br />

3-1/4” Face<br />

J16V 1/2 x 6<br />

Douglas Fir VG<br />

Smooth T&G<br />

1/2” Thick<br />

5-3/16” Face<br />

PANELING AND WAINSCOTING<br />

J15-DF 1/2 x 4<br />

Douglas Fir<br />

B VG V/Smooth SE TG<br />

1/2” Thick<br />

3-1/4” Face<br />

J20 1 x 8<br />

Alpine Knotty<br />

Country Beaded TG<br />

11/16” Thick<br />

6-3/4” Face

J21 1 x 6<br />

Alpine Knotty<br />

Beaded TG<br />

11/16” Thick<br />

5” Face<br />

J23J 7/16 x 4<br />

Pine FJ Primed<br />

Bead-Wall TG<br />

13/32” Thick<br />

3” Face<br />

PANELING AND WAINSCOTING<br />

J21 1 x 6<br />

Pine V-Side<br />

11/16” Thick<br />

5” Face<br />

J24 1 x 6<br />

Douglas Fir B (10% C)<br />

VG Clear Square<br />

Edge TG<br />

3/4” Thick<br />

5-1/4” Face<br />

11

12<br />

J25 1 x 6<br />

Douglas Fir B (10% C)<br />

VG Clear “Eased<br />

Edge” TG<br />

Special Order<br />

3/4” Thick<br />

5-1/4” Face<br />

J29-J 3/4 x 6<br />

House White<br />

V-Side<br />

23/32” Thick<br />

5-1/8” Face<br />

PANELING AND WAINSCOTING<br />

J29-J 3/4 x 6<br />

House White<br />

Beaded TG<br />

23/32” Thick<br />

5-1/8” Face<br />

J46 W 1 x 6<br />

Red Cedar<br />

VG TG “Channel Reveal”<br />

Special Run<br />

11/16” Thick<br />

4-7/8” Face

PANELING AND WAINSCOTING<br />

J46 DF 1 x 6<br />

Douglas Fir<br />

C VG TG “Channel Reveal”<br />

Special Run<br />

11/16” Thick<br />

4-7/8” Face<br />

J48 4 x 8<br />

Victorian Beaded Plywood<br />

Unfinished<br />

3/16” Thick<br />

48” Wide Panel<br />

1-9/16” Pattern Repeat<br />

J47 4 x 8<br />

Arauco Clear Beaded Plywood<br />

2” OC Smooth Plybead<br />

5/16” Thick<br />

48” Wide Panel<br />

2” Pattern Repeat<br />

J53 2 x 6<br />

SPF Select Deck Knotty<br />

TG V<br />

1-7/16” Thick<br />

5” Face<br />

13

14<br />

J54 4 x 8<br />

MDF Preprimed<br />

Harbor Bead<br />

3" OC (1/4")<br />

1/4” Thick<br />

48” Wide Panel<br />

3” Pattern Repeat<br />

J2-12 1 x 12<br />

#1 Knotty Pine<br />

Colonial Bead TG<br />

Special Order<br />

11/16” Thick<br />

10-5/8” Face<br />

PANELING AND WAINSCOTING<br />

J55 4 x 8<br />

MDF Preprimed Nantucket<br />

Bead<br />

1-1/2" OC (1/4")<br />

1/4” Thick<br />

48” Wide Panel<br />

1-1/2” Pattern Repeat<br />

J57 1/2 x 6<br />

AZEK PVC Beaded TG<br />

(18' Only)<br />

1/2” Thick<br />

5-1/8” Face

1/2” Thick<br />

5-1/8” Face<br />

PANELING AND WAINSCOTING<br />

J57 1/2 x 6<br />

AZEK PVC Beaded TG<br />

(18' Only) V-Side<br />

J63 1 x 3<br />

Douglas Fir C VG<br />

“Screenwall”<br />

3/4” Thick<br />

2-1/2” Face<br />

(Not including gap)<br />

J58 2 x 6<br />

Douglas Fir Select Struct “V”<br />

Face / “SE” Back<br />

1-7/16” Thick<br />

5” Face<br />

J63C 1 x 3<br />

Red Cedar Clear<br />

VG “Windscreen”<br />

11/16” Thick<br />

2-1/2” Face<br />

(Not including gap)<br />

15

16<br />

J74C 1 x 4<br />

Red Cedar<br />

Clear VG “Windscreen”<br />

11/16” Thick<br />

3-1/2” Face<br />

(Not including gap)<br />

J74K 1 x 4<br />

SPF Appearance<br />

“Screenwall”<br />

3/4” Thick<br />

3-1/2” Face<br />

(Not including gap)<br />

PANELING AND WAINSCOTING<br />

J74DF 1 x 4<br />

Douglas Fir C VG<br />

“Screenwall”<br />

3/4” Thick<br />

3-1/2” Face<br />

(Not including gap)<br />

W504 1 x 6<br />

Windsor One<br />

Beaded Wainscot<br />

(SPBC6)<br />

23/32” Thick<br />

5-1/8” Face

PANELING AND WAINSCOTING<br />

W504 1 x 6<br />

Windsor One<br />

Beaded Wainscot V-Side<br />

(SPBC6)<br />

23/32” Thick<br />

5-1/8” Face<br />

17

18<br />

Wood has been used as siding for centuries. It provides weather protection<br />

<strong>and</strong> insulation in a wide range of siding types <strong>and</strong> patterns affording<br />

unlimited design possibilities. When properly installed <strong>and</strong> maintained,<br />

wood siding will provide decades <strong>and</strong> decades of service. The ancient temples<br />

of Japan, the 12th century stave churches of Norway, <strong>and</strong> the colonial<br />

houses of New Engl<strong>and</strong> attest to the longevity of a well designed <strong>and</strong><br />

properly constructed wood building.<br />

For best performance, it’s important to select a siding type <strong>and</strong> pattern that<br />

is suited to your local climate. In addition to appearance, several things<br />

must be considered when determining the wood species, the lumber<br />

grade <strong>and</strong> the siding pattern that’s best for your project. Will the building<br />

be subject to driving rain or to hot, dry winds? How wide are the roof<br />

overhangs? Will the siding be installed horizontally or vertically? What kind<br />

of finish will be applied to the siding?<br />

While choosing the right siding may sound complex, a lot of it is just<br />

common sense. Wood has been the siding of choice in the United States for<br />

over 300 years, so there are countless examples to be seen. Take a walk<br />

around you own neighborhood. What siding types <strong>and</strong> patterns have<br />

traditionally been used? Do they complement the buildings’ design? How<br />

are they holding up? The beautiful painted Victorian houses that grace the<br />

Bay Area attest to the natural longevity of painted siding of redwood <strong>and</strong><br />

western red cedar.<br />

SIDING<br />

Even if your design calls for something apart from the commonplace or<br />

traditional, there are a few things to always keep in mind when selecting<br />

wood siding. Narrower patterns shrink <strong>and</strong> swell in width less than wider<br />

ones <strong>and</strong> thus are less likely to cup <strong>and</strong> split as the ambient environment<br />

cycles between wet <strong>and</strong> dry. Thicker patterns have less tendency to cup or<br />

split than thinner ones. Vertical grain siding is roughly twice as<br />

dimensionally stable as flat grain siding, so it holds paint better <strong>and</strong> longer,<br />

<strong>and</strong> is much less likely to cup, split or exhibit raised grain. Clear grades of<br />

siding always outperform knotty grades. Bevel, Dolly Varden, <strong>and</strong> Channel<br />

Rustic siding patterns allow for more dimensional change without adversely<br />

affecting siding appearance than do drop <strong>and</strong> tongue & groove patterns.<br />

Most wood siding is installed horizontally. Vertically installed siding is a<br />

special case that often warrants the use of higher grade siding <strong>and</strong> more<br />

careful installation. All other things being equal, siding patterns that are<br />

narrower, thicker <strong>and</strong> made from clear, vertical grain lumber always<br />

perform best.<br />

The performance of even the best grades of wood siding can be undermined<br />

by improper installation <strong>and</strong> poor maintenance. Fortunately, there are<br />

several excellent guides that spell out how wood siding should be installed<br />

<strong>and</strong> maintained to ensure best performance. We keep on h<strong>and</strong> for distribution<br />

to customers copies of the Western Wood Products Association’s Natural<br />

Wood <strong>Siding</strong> Selection, Installation & Finishing <strong>and</strong> the California Redwood<br />

Association’s <strong>Siding</strong> Patterns <strong>and</strong> Applications. The Canadian Wood

Council’s Wood Reference H<strong>and</strong>book is without equal as a general guide to<br />

the use of wood in building construction. We stock <strong>and</strong> recommend The<br />

Builder’s Guide to Mixed Climates by Joseph Lstiburek.<br />

Poor performance of siding is most often caused by building design flaws,<br />

improper installation, <strong>and</strong> inadequate maintenance. Compared to the<br />

traditional “energy wasters,” today’s energy-efficient houses present a<br />

particular challenge to the performance of wood siding. The main<br />

difference is that the walls of older houses are leaky, warm <strong>and</strong> forgiving<br />

of getting wet, while those of new houses are tight, cold <strong>and</strong> unforgiving.<br />

The result is that wood siding on new houses that gets wet stays wet<br />

longer <strong>and</strong> often accumulates enough moisture to cause problems such as<br />

extractive staining*, mildew <strong>and</strong> peeling paint.<br />

These <strong>and</strong> other moisture-caused problems in wood siding can be avoided<br />

by installing siding according to the rain screen principle. Traditionally,<br />

wood siding is installed directly over sheathing <strong>and</strong> housewrap, with no<br />

gap between the two. With the rain screen principle, siding is installed on<br />

furring strips or over a 3-dimensional plastic mesh to create an air space<br />

between siding <strong>and</strong> sheathing <strong>and</strong> housewrap. The air space allows water<br />

vapor to escape from the rear of the siding as well as from its face. "Rain<br />

screen" siding dries quickly after getting wet, so it doesn’t stay wet long<br />

enough for problems to arise. Furring strips, which are about 1/4 inch thick,<br />

are located over framing members. The air space is screened at the top<br />

SIDING<br />

<strong>and</strong> bottom to keep out insects. Used in the wetter regions of Europe with<br />

great success for more than 30 years, rain screen siding is gaining<br />

acceptance in North America. Installation details can be found in ‘Rain-<br />

Screen Walls: a Better Way to Install <strong>Siding</strong>’ in the February/March 2001<br />

issue of The Taunton Press’ Fine Homebuilding Magazine.<br />

*Western red cedar, redwood, <strong>and</strong> Alaskan yellow cedar are rich in natural organic compounds<br />

called extractives. These compounds impart to these woods their color, aroma <strong>and</strong> decay<br />

resistance. Sometimes, when these woods get wet, the extractives migrate to the surface <strong>and</strong><br />

cause discoloration. These spots are natural, unavoidable, <strong>and</strong> tend to lessen in intensity over<br />

time.<br />

19

20<br />

K31 1 x 8<br />

Redwood Select Heart<br />

Smooth Face<br />

11/16” Thick<br />

7” Face<br />

K33 1 x 6<br />

Redwood Select Heart<br />

Sawtex Face<br />

11/16” Thick<br />

5” Face<br />

NATURAL LUMBER SIDING AND SOFFIT<br />

K31 1 x 8<br />

Redwood Select Heart<br />

Sawtex Face<br />

11/16” Thick<br />

7” Face<br />

K33 1 x 6<br />

Redwood Select Heart<br />

TG Smooth Face V-Side<br />

11/16” Thick<br />

5” Face

K42V 1 x 6<br />

Western Red Cedar Clear<br />

Heart (10% B) Vertical Grain<br />

Sawtex Face TG<br />

3/4” Thick<br />

5-1/4” Face<br />

NATURAL LUMBER SIDING AND SOFFIT<br />

K40V 5/8 x 4<br />

Western Red Cedar Clear<br />

Heart (10% B) Vertical Grain<br />

Sawtex Face TG<br />

5/8” Thick<br />

3-1/2” Face<br />

K40V 5/8 x 4<br />

Western Red Cedar Clear<br />

Heart (10% B) S TG Smooth V<br />

Face<br />

5/8” Thick<br />

3-1/2” Face<br />

K42V 1 x 6<br />

Western Red Cedar Clear<br />

Heart (10% B) Vertical Grain<br />

Smooth V Face<br />

3/4” Thick<br />

5-1/4” Face<br />

21

22<br />

K50V 3/4 x 6<br />

Western Red Cedar Clear<br />

VG Sawtex Bevel<br />

11/16” Thick<br />

5” Face<br />

1/2” Thick<br />

3-1/4” Face<br />

NATURAL LUMBER SIDING AND SOFFIT<br />

K55V 1/2 x 4<br />

Redwood Clear Heart<br />

VG Resawn SE Smooth V TG<br />

Special Order<br />

K55V 1/2 x 4<br />

Redwood Clear Heart<br />

VG Resawn SE TG<br />

Special Order<br />

7/16” Thick<br />

3-1/4” Face<br />

K58V 1 x 6<br />

Redwood Clear Heart<br />

VG R/S TG (11/16” Net)<br />

Resawn<br />

Special Order<br />

11/16” Thick<br />

5-1/8” Face

NATURAL LUMBER SIDING AND SOFFIT<br />

K58V 1 x 6<br />

Redwood Clear Heart<br />

VG R/S TG (11/16” Net)<br />

Smooth<br />

Special Order<br />

11/16” Thick<br />

5-1/8” Face<br />

K59 1 x 6<br />

Western Red Cedar<br />

Tight Knot TG Smooth Side<br />

11/16” Thick<br />

5-1/8” Face<br />

K59 1 x 6<br />

Western Red Cedar<br />

Tight Knot TG Resawn Side<br />

11/16” Thick<br />

5-1/8” Face<br />

23

24<br />

PRIMED HOUSE RED SIDINGS<br />

The patterns featured here are those most commonly used in the Bay<br />

Area over the past 150 years. Found on everything from elegant<br />

Victorians to the sidewalls of refined buildings of the 1920’s <strong>and</strong> 30’s in<br />

such areas as Piedmont, Pacific Heights, <strong>and</strong> St. Francis Woods, they<br />

provide the ideal means of cladding a building in harmony with the<br />

neighborhood’s existing architectural style.<br />

The bulk of the details are stocked in premium quality fingerjointed<br />

western red cedar or redwood. The sidings contain a large percentage of<br />

vertical grain stock for maximum dimensional stability <strong>and</strong> better overall<br />

performance. Unless otherwise noted, each board is finished on all<br />

sides with two coats of a premium stain-blocking primer that improves<br />

topcoat performance. The combination of predominantly vertical grain <strong>and</strong><br />

the two coats of primer greatly minimizes the chance of grain raising <strong>and</strong><br />

extractive staining.

PRIMED HOUSE RED SIDINGS<br />

K1-8J 1 x 8<br />

House Reds<br />

VG FJ-EG Primed “Cove”<br />

11/16” Thick<br />

7” Exposed Face<br />

K4-6J 1 x 6<br />

House Reds<br />

VG FJ-EG Primed “V”<br />

11/16” Thick<br />

5” Face<br />

K1-10J 1 x 10<br />

House Reds<br />

VG FJ-EG Primed “Cove”<br />

11/16” Thick<br />

9” Exposed Face<br />

K4-8J 1 x 8<br />

House Reds<br />

VG FJ-EG Primed “V”<br />

11/16” Thick<br />

7” Exposed Face<br />

25

26<br />

K4-10J 1 x 10<br />

House Reds<br />

VG FJ-EG Primed “V”<br />

11/16” Thick<br />

9” Exposed Face<br />

K5-10J 1 x 10<br />

House Reds<br />

VG FJ-EG Primed “Channel”<br />

11/16” Thick<br />

9” Exposed Face<br />

PRIMED HOUSE RED SIDINGS<br />

K5-8J 1 x 8<br />

House Reds<br />

Primed <strong>Siding</strong> Channel Rustic<br />

11/16” Thick<br />

7” Exposed Face<br />

K6J 1 x 10<br />

House Reds<br />

VG FJ-EG Primed<br />

“Triple Lap”<br />

11/16” Thick<br />

9” Exposed Face

7/8” Thick<br />

7” Exposed Face<br />

PRIMED HOUSE RED SIDINGS<br />

K9-SJ 7/8 x 8<br />

House Reds<br />

FJ/EG VG (10% FG Dev)<br />

Smooth Bevel<br />

K14C 1/2 x 6<br />

House Reds<br />

FJ VG “Clapboard” Bevel<br />

1/2” Thick<br />

4-1/2” Exposed Face<br />

K10-SJ 7/8 x 10<br />

House Reds<br />

FJ/EG VG (10% FG Dev)<br />

Smooth Bevel<br />

7/8” Thick<br />

9” Exposed Face<br />

K45J 1 x 4<br />

House Reds FJ/EG VG<br />

“Belgium Shiplap” SE<br />

Acrylic Primed<br />

11/16” Thick<br />

3-3/16” Exposed Face<br />

27

CEDAR SHINGLES<br />

Wood shingles have a special warmth <strong>and</strong> elegance <strong>and</strong> a classic architectural<br />

look that speaks of quality, taste, <strong>and</strong> timelessness. No other cladding<br />

offers nature’s own formula for unrivaled, weather-defying protection <strong>and</strong><br />

insulation that ensures that your investment will last <strong>and</strong> last. We stock<br />

Stave Lake #1 Blue Certi-Label shingles in both Western Red Cedar <strong>and</strong><br />

Alaskan Yellow Cedar. All of our shingles are 100% heartwood, 100% clear,<br />

<strong>and</strong> 100% vertical grain. <strong>Beronio</strong> is proud to be an associate member of the<br />

Cedar Shake & Shingle Bureau <strong>and</strong> supports the bureau’s dedication to<br />

rigorous quality control <strong>and</strong> technical support. Shingle selection, installation,<br />

finishing details, <strong>and</strong> other information is available at www.cedarbureau.org.<br />

We inventory a wide array of shingles. The most popular is the st<strong>and</strong>ard,<br />

unseasoned KS 10 16” (Five-X) sidewall shingle, which has an A-grade face<br />

<strong>and</strong> butt. 16” Five-X shingles are 2/5 of an inch thick at the butt <strong>and</strong> are<br />

typically installed with 5” of wood exposed to weather. Where tight-fitting,<br />

parallel joints between shingles are desired, our KS 14 Rebutted <strong>and</strong><br />

Rejointed shingles are an ideal choice. All sides <strong>and</strong> ends of R&R shingles<br />

are machine trimmed to have parallel edges that meet at 90 degrees. The<br />

faces have been s<strong>and</strong>ed smooth, providing an ideal surface for finishing.<br />

Five-X R&R’s are available in both Red Cedar <strong>and</strong> Alaskan Yellow Cedar for<br />

those who prefer a lighter colored shingle. We also stock 18” perfections<br />

for those jobs where a larger scale is preferred.<br />

We stock Fanci-Butt red cedar shingles in all of the popular designs.<br />

Whether you’re looking for Fishscale, Round, Diagonal, Arrow, Diamond,<br />

Half-Cove, Hexagonal, Octagonal, or Square, we have the profile in stock<br />

that makes your project unique.<br />

29

30<br />

KSP 1 Shakertown<br />

Shingle Panel<br />

8-1/4” x 96” Panel<br />

7” Exposed Face<br />

KS 10D Bundle Dipped<br />

Special Order<br />

CEDAR SHINGLES<br />

KS 10<br />

16” Red Cedar<br />

Unseasoned “A” Butt<br />

KS 13<br />

16” KD Red Cedar<br />

Stave Lake, Fire Treated<br />

Special Order

CEDAR SHINGLES<br />

KS 14<br />

16” Red Cedar KD<br />

Rebutt/Rejointed Face S<strong>and</strong>ed<br />

KS 99 R&R also available<br />

as 18” Perfections<br />

Rebutt/Rejointed<br />

S<strong>and</strong>ed<br />

FSC Certified<br />

Special Order<br />

Look for<br />

FSC-marked products<br />

KS 16<br />

16” KD Red Cedar<br />

1 Coat Cabot<br />

Bleach/Weather Stain<br />

Special Order<br />

Note: Shown aged 6 months<br />

Southern Exposure<br />

KS 18D Red Cedar<br />

Rebutt/Rejointed S<strong>and</strong>ed<br />

Factory Sealed with<br />

Cabot Clear Oil<br />

Special Order<br />

KS 30<br />

16” Alaskan Yellow Cedar<br />

VG R&R's<br />

Special Order<br />

31

32<br />

PLYWOOD SIDING<br />

Versatile, economical, <strong>and</strong> relatively easy to install, plywood siding has been<br />

used for decades. We proudly stock K-Ply’s Western Red Cedar plywood<br />

siding <strong>and</strong> Roseburg Forest Products’ Breckenridge plywood siding.<br />

K-Ply panels feature a naturally durable western red cedar face <strong>and</strong> back.<br />

Our stock grade is 303:18S which allows up to 18 small solid knots <strong>and</strong>/or<br />

knot holes that have been filled with a cedar-toned filler. Panels with clear<br />

faces are available on a special order basis. <strong>Beronio</strong> <strong>Lumber</strong> also carries K-<br />

Ply’s unique Panel 4 which features a face composed of 4-inch-wide clear red<br />

cedar strips. Panel 4 offers the look of 1 x 4 T&G lumber siding with the<br />

installation ease of plywood.<br />

Breckenridge is Roseburg Forest Products’ premium grade plywood siding.<br />

Produced from selected face veneers with specific grain characteristics, it<br />

st<strong>and</strong>s apart from typical Douglas Fir plywood siding. The carefully selected<br />

faces create a dimensionally stable panel that has no major visual distinction<br />

between sapwood <strong>and</strong> heartwood, resulting in a more uniform grain that<br />

enhances the appearance <strong>and</strong> longevity of applied finishes. For best performance,<br />

Roseburg recommends that the siding be finished with a solid color acrylic<br />

coating. Among all of the wood-base sidings, plywood siding is the most<br />

maintenance-intensive.

PLYWOOD SIDING<br />

KPB<br />

19/32” Breckenridge Hardwood Plain<br />

Face SL<br />

KPB-3<br />

11/32”<br />

KPC-3<br />

11/32” Red Cedar Select Knotty Grade<br />

Plain SL<br />

KPC-5<br />

19/32” Red Cedar Select Knotty Grade<br />

Plain SL<br />

KPB-8<br />

19/32” Breckenridge Hardwood 8”<br />

Groove SL<br />

33<br />

KPC8-5<br />

19/32” Red Cedar Select Knotty Grade<br />

8” Groove

HARDIPLANK<br />

Hardiplank is a new lap siding product that combines the durability<br />

of fiber-cement with the look of wood. Manufactured from Portl<strong>and</strong><br />

cement, s<strong>and</strong> <strong>and</strong> wood fiber, the siding is durable, economical,<br />

<strong>and</strong> comes factory-primed. Hardiplank will not rot, is immune to<br />

permanent water damage, is not attacked by insects, holds paint<br />

extremely well, carries a Class A fire rating <strong>and</strong> is backed by a<br />

50-year limited transferable warranty when installed in accordance<br />

with the manufacturer’s instructions. While no synthetic siding is<br />

an exact match for traditional wood siding, James Hardie’s textured<br />

products harmonize with traditional architecture.<br />

Sold in panels, James Hardie’s Shingleside combines the look of<br />

an authentic wood shingle with the ease of panel installation.<br />

Shingleside is backed by a limited 30-year warranty. Unfortunately,<br />

factory-priming is not yet available for Shingleside.<br />

Information on the entire line of James Hardie siding products,<br />

as well as installation <strong>and</strong> finishing instructions can be found at<br />

www.jameshardie.com.<br />

35

36<br />

KH-9<br />

9-1/4” Hardiplank Smooth<br />

Preprimed Smooth Lap<br />

5/16” Thick<br />

8” Exposed Face<br />

KH-8CR<br />

8” Hardiplank Primed Colonial<br />

Rough Sawn<br />

5/16” Thick<br />

6-3/4” Exposed Face<br />

PRIMED FIBER - CEMENT SIDINGS<br />

KH-8C<br />

8” Hardiplank Factory Primed<br />

Colonial Lap<br />

5/16” Thick<br />

6-3/4” Exposed Face<br />

KH-8<br />

8-1/4” Hardiplank Smooth<br />

Preprimed Smooth Lap<br />

5/16” Thick<br />

7” Exposed Face

PRIMED FIBER - CEMENT SIDINGS<br />

KG-1 GAF Weatherside<br />

Fiber Cement Shingle<br />

12” x 24”<br />

11” Exposed Face<br />

37

38<br />

Selecting the right finish for your wood siding is critical to maintaining<br />

its appearance <strong>and</strong> performance over time. For information beyond<br />

what is presented in this primer on finish types, we recommend The<br />

Forest Products Society's Finishes for Exterior Wood as an excellent<br />

overall guide.<br />

Paints, solid-color stains, clear coatings, water repellents, <strong>and</strong><br />

semitransparent stains are applied to wood siding to enhance its<br />

appearance <strong>and</strong> to protect it from the elements. These <strong>and</strong> other finishes<br />

are classified as either film-forming or penetrating. Both types can be<br />

either water-borne (also known as latex) or oil-base. Upon drying, filmforming<br />

finishes—primers, paints, solid-color stains, <strong>and</strong> clear<br />

coatings—coalesce into a thin continuous sheet that sits on top of the<br />

wood. Of all coating types, film-forming finishes provide the greatest<br />

protection to wood by virtue of the physical barrier they pose to the<br />

elements. Penetrating finishes, on the other h<strong>and</strong>, do not form surface<br />

films, but rather are absorbed into the wood. Water repellents <strong>and</strong><br />

semitransparent stains fall into this category. Effective in controlling<br />

surface checking, penetrating finishes do not stop wood from weathering.<br />

The type of finish, the properties of the wood to which it is applied, local<br />

climate, <strong>and</strong> directional exposure influence the performance <strong>and</strong><br />

longevity of coatings applied to exterior wood products. All other things<br />

being equal, paints last longest, followed closely by solid-color stains,<br />

with semitransparent stains, water repellents, <strong>and</strong> clear coatings all<br />

about an equally distant third. All other things being equal, finishes last<br />

longest on vertical grained surfaces of low density softwoods whose<br />

moisture content stays below about 16 percent. All other things being<br />

FINISHES FOR WOOD SIDING<br />

equal, coatings last longest on a building’s northern exposure <strong>and</strong> on<br />

those parts of a building that are sheltered from rain.<br />

Finishes can be applied to new wood siding in a factory or on site.<br />

Because of its many advantages, factory-finishing of siding is fast<br />

becoming the norm. Here, all sides of every piece of siding—face, back,<br />

edges, <strong>and</strong> ends—are machine-coated with a primer <strong>and</strong>, if desired, with<br />

one or more topcoats. Because the siding arrives at the jobsite already<br />

backprimed <strong>and</strong> topcoated, field finishing costs are reduced or eliminated,<br />

<strong>and</strong> the siding has instant protection from the elements. Site-cut edges<br />

<strong>and</strong> ends, of course, must be re-primed before siding is installed.<br />

Likewise, the back, edges, <strong>and</strong> ends of new bare wood siding that will be<br />

finished in the field should be primed before siding is installed. The face<br />

should be primed within two weeks of the siding being installed,<br />

otherwise it will have to be lightly s<strong>and</strong>ed to remove contaminants <strong>and</strong> to<br />

reactivate the wood for good adhesion. Such surface preparation is, of<br />

course, not possible with roughsawn siding. Best adhesion is achieved on<br />

both smooth <strong>and</strong> rough siding when finishes are worked into surface<br />

irregularities by brushing. Finishes applied on-site by spraying or rolling<br />

should be back-brushed for this reason.<br />

FILM-FORMING FINISHES<br />

PRIMERS—Applied to bare wood in advance of paints <strong>and</strong> solid-color<br />

stains, a primer creates a smooth base for the topcoat to adhere to, <strong>and</strong><br />

serves as a chemical barrier between the wood <strong>and</strong> the topcoat. Best<br />

performance is obtained with a primer that contains a fungicide to stop<br />

mildew <strong>and</strong> a stain-blocker that prevents water-soluble extractives in<br />

wood from discoloring topcoats.

PAINTS—Paints are opaque coatings that, in addition to their decorative<br />

function, protect wood by blocking the sun’s ultraviolet rays, repelling<br />

liquid water, retarding the absorption of water vapor, <strong>and</strong> preventing<br />

erosion. For each wet coat applied, a dry film 2 or 3 mils thick (1 mil<br />

equals 0.001 inches) is left behind. Oil-base paints generally have lower<br />

permeability to water vapor <strong>and</strong> are less flexible over time than waterborne<br />

paints. As a consequence, oil-base paints are more susceptible to<br />

cracking <strong>and</strong> peeling occasioned by swelling <strong>and</strong> shrinking of the<br />

underlying wood. Performance <strong>and</strong> longevity of paints can be enhanced<br />

by treating bare wood with a “paintable” water repellent prior to priming.<br />

Paint’s best performance is obtained when two topcoats of 100 percent<br />

acrylic latex paint with fungicide are applied over a primer containing<br />

fungicide <strong>and</strong> stain-blocker. Depending on local climate <strong>and</strong> severity of<br />

exposure, such a system should give 7 to 10 years of good<br />

performance before refinishing is needed.<br />

SOLID-COLOR STAINS—Solid-color stains are essentially thin paints, with<br />

a one-coat dry film thickness of about 1 mil. The thinness of the film<br />

permits both liquid water <strong>and</strong> water vapor to pass more easily into <strong>and</strong> out<br />

of the wood. Though some solid-color stains can be applied directly to<br />

bare wood, most benefit from being applied over a compatible primer<br />

containing fungicide <strong>and</strong> stain-blocker. Application of a “paintable” water<br />

repellent prior to priming further improves performance <strong>and</strong> longevity. As<br />

with paints, best performance is achieved with a three-coat system of<br />

primer containing fungicide <strong>and</strong> stain-blocker <strong>and</strong> two top coats of 100<br />

percent acrylic latex solid-color stain with fungicide. Depending on the<br />

environment, this system should give 3 to 7 years of satisfactory service<br />

before maintenance is required.<br />

CLEAR COATINGS—Essentially paints without pigment, varnishes,<br />

urethanes, <strong>and</strong> other clear coatings require frequent maintenance. The<br />

sun’s ultraviolet rays pass through these transparent finishes <strong>and</strong> slowly<br />

degrade the wood. In usually two years or less, even the toughest clear<br />

finishes often crack <strong>and</strong> peel. Additives that block or absorb ultraviolet light<br />

slightly lengthen the service life of clear coatings. Best performance is<br />

obtained by applying a “paintable” water repellent to the bare wood,<br />

followed by three or more coats of finish.<br />

PENETRATING FINISHES<br />

WATER REPELLENTS—Used on exterior wood that is otherwise<br />

unfinished, water repellents retard absorption of liquid water by wood,<br />

causing dew, rain, <strong>and</strong> snow melt to bead on the surface where it can<br />

harmlessly evaporate. Effective in limiting warping, surface checking, <strong>and</strong><br />

end splitting, these penetrating finishes do not prevent wood from turning<br />

gray. Most water repellents are oil-based; some contain a fungicide to<br />

discourage mildew. Applied liberally by brushing or spraying, water<br />

repellents are readily absorbed into smooth <strong>and</strong> rough wood. Because<br />

water repellents applied to otherwise unfinished wood remain effective for<br />

only 1 or 2 years, they must be reapplied regularly. So-called “paintable”<br />

water repellents are applied directly to bare wood before the primer to<br />

enhance the performance <strong>and</strong> longevity of paints <strong>and</strong> solid-color stains by<br />

reducing extractive staining, <strong>and</strong> blistering <strong>and</strong> peeling.<br />

SEMITRANSPARENT STAINS—An excellent choice for roughsawn or<br />

weathered wood, semitransparent stains impart color to wood without<br />

hiding its natural texture. If used on new smooth wood, only a single coat<br />

of semitransparent stain should be applied initially. Otherwise, a film may<br />

form; surfaces may appear glossy <strong>and</strong> later begin to flake because of<br />

smooth wood’s inability to absorb the second coat. Additional coats can<br />

be applied once smooth surfaces have become more absorptive after<br />

weathering for 1 or 2 years. Semitransparent stains provide to wood only<br />

slightly more protection from the elements than water repellents.<br />

Reapplication is usually necessary every 3 to 4 years.<br />

39

SIDING: INSTALLATION DETAILS<br />

A rainscreen installation uses furring strips, or breather mesh, to maintain<br />

an air space behind the siding. The air gap provides improved drainage,<br />

better drying, reduces the chance of rot, increases the service life of the<br />

coating system, <strong>and</strong> is generally much easier on the siding by allowing it<br />

to “breathe.” The technique was first developed in the wet climates of<br />

Northern Europe <strong>and</strong> Canada in an effort to help accomodate siding<br />

problems caused by modern “air-tight” construction. The results have<br />

been dramatic. Now, the “rainscreen” system is beginning to gain<br />

acceptance in North America. We do not have the training to design entire<br />

systems. The panels depicted here are presented to show how the<br />

system works in principle, <strong>and</strong> are not intended as specific designs. The<br />

Building Science Corporation (www.buildingscience.com) contains a<br />

wealth of information regarding “rainscreen” design <strong>and</strong> is a great source<br />

for more specific details.<br />

40 Shingle Board Showing<br />

“Home Slicker”<br />

Edge Profile of Above Panel Construction<br />

Rainscreen with siding <strong>and</strong> 3/8” ply furring<br />

strips

NOTES

2525 MARIN STREET<br />

SAN FRANCISCO, CA 94124<br />

TEL: 415-824-4300<br />

FAX: 415-824-3706<br />

WWW.BERONIO.COM