Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NOTES: Standard <strong>Keyway</strong> Mandrels not suitable for<br />

blind holes. Blind Hole <strong>Keyway</strong> Mandrels and Stones<br />

are available on special order basis. Available 4 weeks<br />

after receipt of order.<br />

These honing units are designed to be used for honing<br />

bores with keyways, splines, ports and other surface<br />

interruptions.<br />

<strong>Keyway</strong> Mandrels must be trued accurately to keep<br />

the honing stone from hanging up in the keyway. Size<br />

Truing Sleeve to a diameter between the desired finish<br />

bore size and ,127 mm (.005") under.<br />

In some cases, stones other than<br />

the RECOMMENDED STONES<br />

may hone faster or last longer.<br />

For long or repetitive production<br />

runs, it may be economical to<br />

choose a stone slightly harder or<br />

softer, coarser or finer. As a general<br />

rule, hard materials require<br />

soft stones; soft materials<br />

require hard stones; rough holes<br />

require hard stones.<br />

☛Stone orders involving large quantities<br />

or unusual requirements available<br />

2 - 4 weeks after receipt of order.<br />

*1st choice<br />

**2nd choice.<br />

Use if A55<br />

does not cut.<br />

}<br />

Hard-----Soft<br />

Hard---Soft<br />

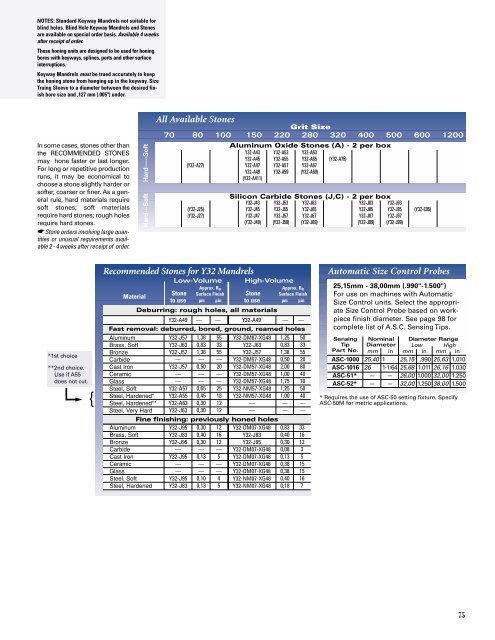

All Available Stones<br />

Grit Size<br />

70 80 100 150 220 280 320 400 500 600 1200<br />

(Y32-A27)<br />

(Y32-J25)<br />

(Y32-J27)<br />

Aluminum Oxide Stones (A) - 2 per box<br />

Y32-A43<br />

Y32-A45<br />

Y32-A47<br />

Y32-A49<br />

(Y32-A411)<br />

Y32-A53<br />

Y32-A55<br />

Y32-A57<br />

Y32-A59<br />

Y32-A63<br />

Y32-A65<br />

Y32-A67<br />

(Y32-A69)<br />

(Y32-A75)<br />

Silicon Carbide Stones (J,C) - 2 per box<br />

Y32-J43<br />

Y32-J45<br />

Y32-J47<br />

(Y32-J49)<br />

Recommended Stones for Y32 Mandrels<br />

Y32-J53<br />

Y32-J55<br />

Y32-J57<br />

(Y32-J59)<br />

Y32-J63<br />

Y32-J65<br />

Y32-J67<br />

(Y32-J69)<br />

Low-Volume High-Volume<br />

Material<br />

Stone<br />

to use<br />

Approx. Ra<br />

Surface Finish<br />

µm µin<br />

Stone<br />

to use<br />

Approx. Ra<br />

Surface Finish<br />

µm µin<br />

Deburring: rough holes, all materials<br />

Y32-A49 — — Y32-A49 — —<br />

Fast removal: deburred, bored, ground, reamed holes<br />

Aluminum<br />

Y32-J57 1,38 55 Y32-DM87-XG48 1,25 50<br />

Brass, Soft<br />

Y32-J63 0,83 33 Y32-J63 0,83 33<br />

Bronze<br />

Y32-J57 1,38 55 Y32-J57 1,38 55<br />

Carbide<br />

— — — Y32-DM57-XG48 0,50 20<br />

Cast Iron<br />

Y32-J57 0,50 20 Y32-DM57-XG48 2,00 80<br />

Ceramic<br />

— — — Y32-DM57-XG48 1,00 40<br />

Glass<br />

— — — Y32-DM57-XG48 1,75 70<br />

Steel, Soft<br />

Y32-A57 0,65 25 Y32-NM57-XG48 1,25 50<br />

Steel, Hardened* Y32-A55 0,45 18 Y32-NM57-XG48 1,00 40<br />

Steel, Hardened** Y32-A63 0,30 12<br />

—<br />

— —<br />

Steel, Very Hard Y32-J63 0,30 12<br />

—<br />

— —<br />

Fine finishing: previously honed holes<br />

Aluminum<br />

Y32-J95 0,30 12 Y32-DM07-XG48 0,83 33<br />

Brass, Soft<br />

Y32-J83 0,40 16 Y32-J83 0,40 16<br />

Bronze<br />

Y32-J95 0,30 12 Y32-J95 0,30 12<br />

Carbide<br />

— — — Y32-DM07-XG48 0,08 3<br />

Cast Iron<br />

Y32-J95 0,13 5 Y32-DM07-XG48 0,13 5<br />

Ceramic<br />

— — — Y32-DM07-XG48 0,38 15<br />

Glass<br />

— — — Y32-DM07-XG48 0,38 15<br />

Steel, Soft<br />

Y32-J95 0,10 4 Y32-NM07-XG48 0,40 16<br />

Steel, Hardened Y32-J83 0,13 5 Y32-NM07-XG48 0,18 7<br />

Y32-J83<br />

Y32-J85<br />

Y32-J87<br />

(Y32-J89)<br />

Y32-J93<br />

Y32-J95<br />

Y32-J97<br />

(Y32-J99)<br />

(Y32-CO5)<br />

Automatic Size Control Probes<br />

25,15mm - 38,00mm (.990"-1.500")<br />

For use on machines with Automatic<br />

Size Control units. Select the appropriate<br />

Size Control Probe based on workpiece<br />

finish diameter. See page 98 for<br />

complete list of A.S.C. Sensing Tips.<br />

Sensing Nominal Diameter Range<br />

Tip<br />

Part No.<br />

Diameter<br />

mm in<br />

Low<br />

mm in<br />

High<br />

mm in<br />

ASC-1000 25,40 1 25,15 .990 25,63 1.010<br />

ASC-1016 26 1-1/64 25,68 1.011 26,16 1.030<br />

ASC-51* — — 26,00 1.000 32,00 1.250<br />

ASC-52* — — 32,00 1.250 38,00 1.500<br />

* Requires the use of ASC-50 setting fixture. Specify<br />

ASC-50M for metric applications.<br />

75