ds4-50_4-60_4-70 PERMA-CRETE Acrylic Texture Coating P ...

ds4-50_4-60_4-70 PERMA-CRETE Acrylic Texture Coating P ...

ds4-50_4-60_4-70 PERMA-CRETE Acrylic Texture Coating P ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4-<strong>50</strong><br />

4-<strong>60</strong><br />

<strong>PERMA</strong>-<strong>CRETE</strong> <strong>PERMA</strong>-<strong>CRETE</strong>®<br />

Acr <strong>Acrylic</strong> Acr ylic T T<strong>Texture</strong><br />

T exture <strong>Coating</strong><br />

<strong>Coating</strong><br />

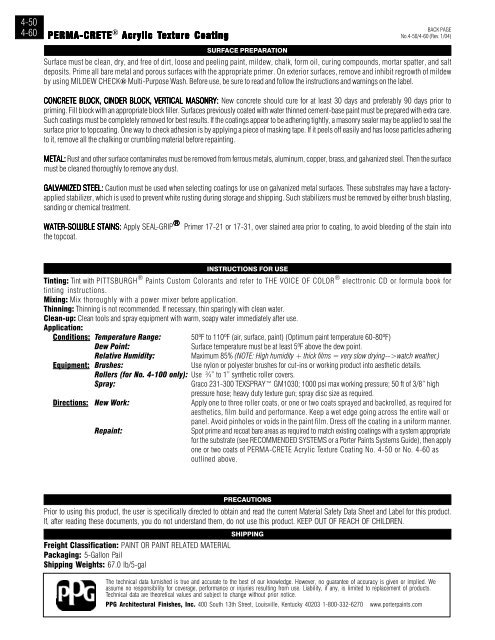

Surface must be clean, dry, and free of dirt, loose and peeling paint, mildew, chalk, form oil, curing compounds, mortar spatter, and salt<br />

deposits. Prime all bare metal and porous surfaces with the appropriate primer. On exterior surfaces, remove and inhibit regrowth of mildew<br />

by using MILDEW CHECK® Multi-Purpose Wash. Before use, be sure to read and follow the instructions and warnings on the label.<br />

CON<strong>CRETE</strong> CON<strong>CRETE</strong> CON<strong>CRETE</strong> BL BL BLOCK, BL OCK, CINDER CINDER BL BLOCK, BL OCK, VER VERTICAL VER TICAL MASONRY<br />

MASONRY:<br />

MASONRY : New concrete should cure for at least 30 days and preferably 90 days prior to<br />

priming. Fill block with an appropriate block filler. Surfaces previously coated with water thinned cement-base paint must be prepared with extra care.<br />

Such coatings must be completely removed for best results. If the coatings appear to be adhering tightly, a masonry sealer may be applied to seal the<br />

surface prior to topcoating. One way to check adhesion is by applying a piece of masking tape. If it peels off easily and has loose particles adhering<br />

to it, remove all the chalking or crumbling material before repainting.<br />

METAL: METAL: Rust and other surface contaminates must be removed from ferrous metals, aluminum, copper, brass, and galvanized steel. Then the surface<br />

must be cleaned thoroughly to remove any dust.<br />

GAL GALVANIZED GAL VANIZED STEEL: STEEL: Caution must be used when selecting coatings for use on galvanized metal surfaces. These substrates may have a factoryapplied<br />

stabilizer, which is used to prevent white rusting during storage and shipping. Such stabilizers must be removed by either brush blasting,<br />

sanding or chemical treatment.<br />

WATER WATER-SOL<br />

WATER -SOL -SOLUBLE -SOLUBLE<br />

UBLE STAINS: STAINS: STAINS: Apply SEAL-GRIP ® Primer 17-21 or 17-31, over stained area prior to coating, to avoid bleeding of the stain into<br />

the topcoat.<br />

Tinting: Tint with PITTSBURGH ® Paints Custom Colorants and refer to THE VOICE OF COLOR ® INSTRUCTIONS FOR USE<br />

electtronic CD or formula book for<br />

tinting instructions.<br />

Mixing: Mix thoroughly with a power mixer before application.<br />

Thinning: Thinning is not recommended. If necessary, thin sparingly with clean water.<br />

Clean-up: Clean tools and spray equipment with warm, soapy water immediately after use.<br />

Application:<br />

Conditions: Temperature Range: <strong>50</strong>ºF to 110ºF (air, surface, paint) (Optimum paint temperature <strong>60</strong>-80ºF)<br />

Dew Point: Surface temperature must be at least 5ºF above the dew point.<br />

Relative Humidity: Maximum 85% (NOTE: High humidity + thick films = very slow drying-->watch weather.)<br />

Equipment: Brushes: Use nylon or polyester brushes for cut-ins or working product into aesthetic details.<br />

Rollers (for No. 4-100 only): Use ¾” to 1” synthetic roller covers.<br />

Spray: Graco 231-300 TEXSPRAY GM1030; 1000 psi max working pressure; <strong>50</strong> ft of 3/8” high<br />

pressure hose; heavy duty texture gun; spray disc size as required.<br />

Directions: New Work: Apply one to three roller coats, or one or two coats sprayed and backrolled, as required for<br />

aesthetics, film build and performance. Keep a wet edge going across the entire wall or<br />

panel. Avoid pinholes or voids in the paint film. Dress off the coating in a uniform manner.<br />

Repaint: Spot prime and recoat bare areas as required to match existing coatings with a system appropriate<br />

for the substrate (see RECOMMENDED SYSTEMS or a Porter Paints Systems Guide), then apply<br />

one or two coats of <strong>PERMA</strong>-<strong>CRETE</strong> <strong>Acrylic</strong> <strong>Texture</strong> <strong>Coating</strong> No. 4-<strong>50</strong> or No. 4-<strong>60</strong> as<br />

outlined above.<br />

Freight Classification: PAINT OR PAINT RELATED MATERIAL<br />

Packaging: 5-Gallon Pail<br />

Shipping Weights: 67.0 lb/5-gal<br />

SURFACE PREPARATION<br />

BACK PAGE<br />

No.4-<strong>50</strong>/4-<strong>60</strong> (Rev. 1/04)<br />

PRECAUTIONS<br />

Prior to using this product, the user is specifically directed to obtain and read the current Material Safety Data Sheet and Label for this product.<br />

If, after reading these documents, you do not understand them, do not use this product. KEEP OUT OF REACH OF CHILDREN.<br />

SHIPPING<br />

The technical data furnished is true and accurate to the best of our knowledge. However, no guarantee of accuracy is given or implied. We<br />

assume no responsibility for coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products.<br />

Technical data are theoretical values and subject to change without prior notice.<br />

PPG Architectural Finishes, Inc. 400 South 13th Street, Louisville, Kentucky 40203 1-800-332-62<strong>70</strong> www.porterpaints.com