Removal of solvent-based ink from printed surface of HDPE bottles ...

Removal of solvent-based ink from printed surface of HDPE bottles ...

Removal of solvent-based ink from printed surface of HDPE bottles ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

986<br />

<strong>surface</strong> to become more positive. The <strong>of</strong>fered explanation<br />

agreed well with the point <strong>of</strong> charge reversal (PZC)<br />

observed in Fig. 7 (i.e., blown-up plots <strong>from</strong> Fig. 5a shown<br />

with the linear scale on the x-axis). With increasing alkyl<br />

chain length <strong>of</strong> the CnTAB molecules, the PZC was<br />

observed at about 0.17 mM for DTAB, 0.07 mM for TTAB,<br />

and 0.03 mM for CTAB. Therefore, charge reversal <strong>of</strong> the<br />

<strong>ink</strong> occurs at a lower concentration as the alkyl chain length<br />

<strong>of</strong> the surfactant increases. The results are consistent with<br />

the observed increase in the wettability with increasing<br />

alkyl chain length <strong>of</strong> the CnTAB molecules in the framework<br />

<strong>of</strong> increasing surfactant adsorption with increasing<br />

alkyl chain length and increasing surfactant concentration.<br />

Solubilization<br />

Solubilization <strong>of</strong> <strong>ink</strong> binder in surfactant micelles is a very<br />

important step for the de<strong>ink</strong>ing process. <strong>Removal</strong> <strong>of</strong> the<br />

binder <strong>from</strong> the <strong>surface</strong> is necessary to permit removal <strong>of</strong><br />

the colored pigment particles (de<strong>ink</strong>ing). It has been<br />

hypothesized in a previous work that it is the negative<br />

charge on the binder (carboxylate groups) which is the<br />

cause <strong>of</strong> the effectiveness <strong>of</strong> cationic surfactants relative to<br />

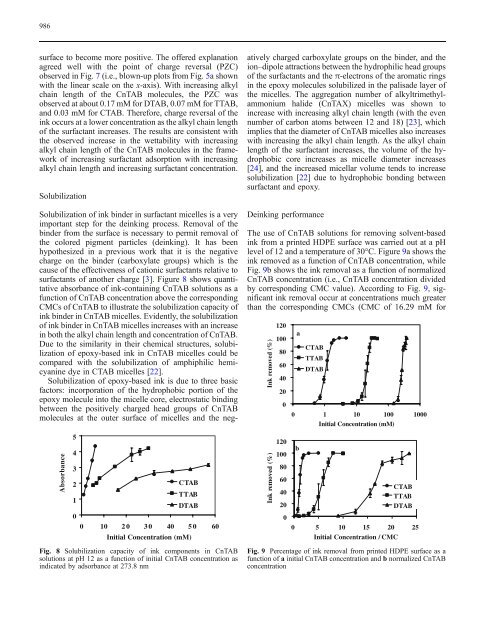

surfactants <strong>of</strong> another charge [3]. Figure 8 shows quantitative<br />

absorbance <strong>of</strong> <strong>ink</strong>-containing CnTAB solutions as a<br />

function <strong>of</strong> CnTAB concentration above the corresponding<br />

CMCs <strong>of</strong> CnTAB to illustrate the solubilization capacity <strong>of</strong><br />

<strong>ink</strong> binder in CnTAB micelles. Evidently, the solubilization<br />

<strong>of</strong> <strong>ink</strong> binder in CnTAB micelles increases with an increase<br />

in both the alkyl chain length and concentration <strong>of</strong> CnTAB.<br />

Due to the similarity in their chemical structures, solubilization<br />

<strong>of</strong> epoxy-<strong>based</strong> <strong>ink</strong> in CnTAB micelles could be<br />

compared with the solubilization <strong>of</strong> amphiphilic hemicyanine<br />

dye in CTAB micelles [22].<br />

Solubilization <strong>of</strong> epoxy-<strong>based</strong> <strong>ink</strong> is due to three basic<br />

factors: incorporation <strong>of</strong> the hydrophobic portion <strong>of</strong> the<br />

epoxy molecule into the micelle core, electrostatic binding<br />

between the positively charged head groups <strong>of</strong> CnTAB<br />

molecules at the outer <strong>surface</strong> <strong>of</strong> micelles and the neg-<br />

Absorbance<br />

5<br />

4<br />

3<br />

2<br />

CTAB<br />

1<br />

0<br />

TTAB<br />

DTAB<br />

0 10 20 30 40 50 60<br />

Initial Concentration (mM)<br />

Fig. 8 Solubilization capacity <strong>of</strong> <strong>ink</strong> components in CnTAB<br />

solutions at pH 12 as a function <strong>of</strong> initial CnTAB concentration as<br />

indicated by adsorbance at 273.8 nm<br />

atively charged carboxylate groups on the binder, and the<br />

ion–dipole attractions between the hydrophilic head groups<br />

<strong>of</strong> the surfactants and the π-electrons <strong>of</strong> the aromatic rings<br />

in the epoxy molecules solubilized in the palisade layer <strong>of</strong><br />

the micelles. The aggregation number <strong>of</strong> alkyltrimethylammonium<br />

halide (CnTAX) micelles was shown to<br />

increase with increasing alkyl chain length (with the even<br />

number <strong>of</strong> carbon atoms between 12 and 18) [23], which<br />

implies that the diameter <strong>of</strong> CnTAB micelles also increases<br />

with increasing the alkyl chain length. As the alkyl chain<br />

length <strong>of</strong> the surfactant increases, the volume <strong>of</strong> the hydrophobic<br />

core increases as micelle diameter increases<br />

[24], and the increased micellar volume tends to increase<br />

solubilization [22] due to hydrophobic bonding between<br />

surfactant and epoxy.<br />

De<strong>ink</strong>ing performance<br />

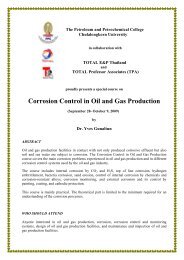

The use <strong>of</strong> CnTAB solutions for removing <strong>solvent</strong>-<strong>based</strong><br />

<strong>ink</strong> <strong>from</strong> a <strong>printed</strong> <strong>HDPE</strong> <strong>surface</strong> was carried out at a pH<br />

level <strong>of</strong> 12 and a temperature <strong>of</strong> 30°C. Figure 9a shows the<br />

<strong>ink</strong> removed as a function <strong>of</strong> CnTAB concentration, while<br />

Fig. 9b shows the <strong>ink</strong> removal as a function <strong>of</strong> normalized<br />

CnTAB concentration (i.e., CnTAB concentration divided<br />

by corresponding CMC value). According to Fig. 9, significant<br />

<strong>ink</strong> removal occur at concentrations much greater<br />

than the corresponding CMCs (CMC <strong>of</strong> 16.29 mM for<br />

Ink removed (%)<br />

Ink removed (%)<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

a<br />

CTAB<br />

TTAB<br />

DTAB<br />

0 1 10 100 1000<br />

Initial Concentration (mM)<br />

b<br />

CTAB<br />

TTAB<br />

DTAB<br />

0 5 10 15 20 25<br />

Initial Concentration / CMC<br />

Fig. 9 Percentage <strong>of</strong> <strong>ink</strong> removal <strong>from</strong> <strong>printed</strong> <strong>HDPE</strong> <strong>surface</strong> as a<br />

function <strong>of</strong> a initial CnTAB concentration and b normalized CnTAB<br />

concentration