3-Way Temperature Control Valve - Amot

3-Way Temperature Control Valve - Amot

3-Way Temperature Control Valve - Amot

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

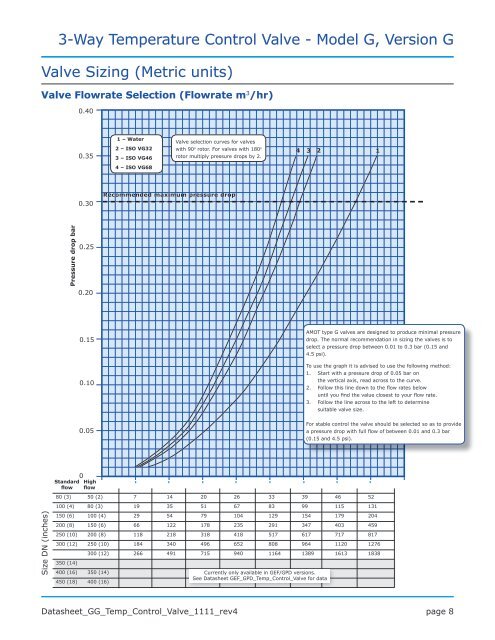

3-<strong>Way</strong> <strong>Temperature</strong> <strong>Control</strong> <strong>Valve</strong> - Model G, Version G<br />

<strong>Valve</strong> Sizing (Metric units)<br />

<strong>Valve</strong> Flowrate Selection (Flowrate m 3 /hr)<br />

Size DN (inches)<br />

Pressure drop bar<br />

0<br />

Standard High<br />

flow s flow<br />

s s s s s s s s<br />

80 (3) 50 (2) 7 14 20 26 33 39 46 52<br />

100 (4) 80 (3) 19 35 51 67 83 99 115 131<br />

150 (6) 100 (4) 29 54 79 104 129 154 179 204<br />

200 (8) 150 (6) 66 122 178 235 291 347 403 459<br />

250 (10) 200 (8) 118 218 318 418 517 617 717 817<br />

300 (12) 250 (10) 184 340 496 652 808 964 1120 1276<br />

350 (14)<br />

0.40<br />

0.35<br />

0.30<br />

0.25<br />

0.20<br />

0.15<br />

0.10<br />

0.05<br />

400 (16) 350 (14)<br />

450 (18) 400 (16)<br />

1 – Water<br />

2 – ISO VG32<br />

3 – ISO VG46<br />

4 – ISO VG68<br />

<strong>Valve</strong> selection curves for valves<br />

with 90 o rotor. For valves with 180 o<br />

rotor multiply pressure drops by 2.<br />

Recommended maximum pressure drop<br />

300 (12) 266 491 715 940 1164 1389 1613 1838<br />

Datasheet_GG_Temp_<strong>Control</strong>_<strong>Valve</strong>_1111_rev4<br />

4 3 2<br />

1<br />

AMOT type G valves are designed to produce minimal pressure<br />

drop. The normal recommendation in sizing the valves is to<br />

select a pressure drop between 0.01 to 0.3 bar (0.15 and<br />

4.5 psi).<br />

Currently only available in GEF/GPD versions.<br />

See Datasheet GEF_GPD_Temp_<strong>Control</strong>_<strong>Valve</strong> for data<br />

To use the graph it is advised to use the following method:<br />

1. Start with a pressure drop of 0.05 bar on<br />

the vertical axis, read across to the curve.<br />

2. Follow this line down to the flow rates below<br />

until you find the value closest to your flow rate.<br />

3. Follow the line across to the left to determine<br />

suitable valve size.<br />

For stable control the valve should be selected so as to provide<br />

a pressure drop with full flow of between 0.01 and 0.3 bar<br />

(0.15 and 4.5 psi).<br />

page 8