Ceramic Capacitors

Ceramic Capacitors

Ceramic Capacitors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

Aluminum Electrolytic <strong>Capacitors</strong><br />

Aluminum electrolytics offer some of the smallest sizes for a given capacitance and voltage. Commonly<br />

used for filtering and bulk energy storage, electrolytics are available in rated voltages exceeding 500 VDC.<br />

KEMET Electrolytic capacitors are utilized in a wide variety of demanding power electronics applications<br />

such as automotive, power generators and converters, welders, wind turbines, uninterruptible power<br />

supplies, and medical imaging.<br />

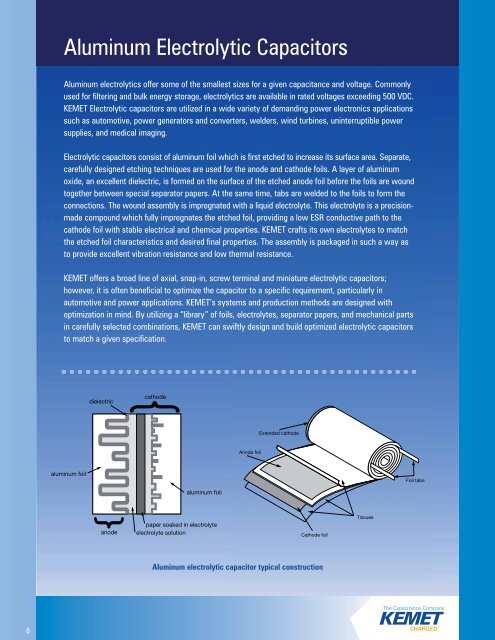

Electrolytic capacitors consist of aluminum foil which is first etched to increase its surface area. Separate,<br />

carefully designed etching techniques are used for the anode and cathode foils. A layer of aluminum<br />

oxide, an excellent dielectric, is formed on the surface of the etched anode foil before the foils are wound<br />

together between special separator papers. At the same time, tabs are welded to the foils to form the<br />

connections. The wound assembly is impregnated with a liquid electrolyte. This electrolyte is a precisionmade<br />

compound which fully impregnates the etched foil, providing a low ESR conductive path to the<br />

cathode foil with stable electrical and chemical properties. KEMET crafts its own electrolytes to match<br />

the etched foil characteristics and desired final properties. The assembly is packaged in such a way as<br />

to provide excellent vibration resistance and low thermal resistance.<br />

KEMET offers a broad line of axial, snap-in, screw terminal and miniature electrolytic capacitors;<br />

however, it is often beneficial to optimize the capacitor to a specific requirement, particularly in<br />

automotive and power applications. KEMET’s systems and production methods are designed with<br />

optimization in mind. By utilizing a “library” of foils, electrolytes, separator papers, and mechanical parts<br />

in carefully selected combinations, KEMET can swiftly design and build optimized electrolytic capacitors<br />

to match a given specification.<br />

aluminum foil<br />

dielectric<br />

anode<br />

cathode<br />

aluminum foil<br />

paper soaked in electrolyte<br />

electrolyte solution<br />

Anode foil<br />

Extended cathode<br />

Cathode foil<br />

Aluminum electrolytic capacitor typical construction<br />

Tissues<br />

Foil tabs