ONTIME Product Catalog 2013 EAS Accessories

ONTIME Product Catalog 2013 EAS Accessories

ONTIME Product Catalog 2013 EAS Accessories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

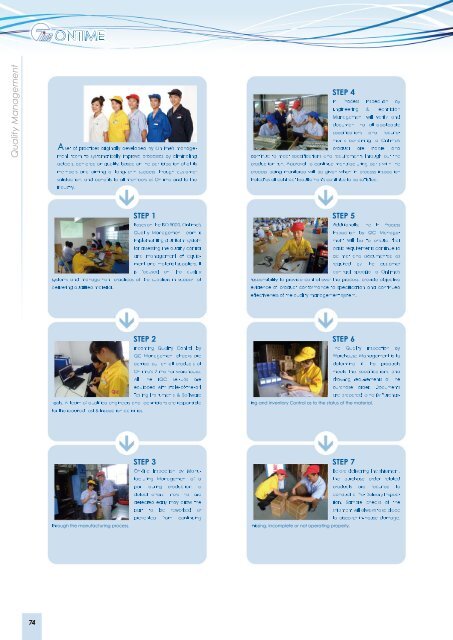

Quality Management<br />

74<br />

<strong>ONTIME</strong><br />

A<br />

set of practices originaly developed by OnTime's management<br />

team to systematicaly improve proceses by eliminating<br />

defects, centered on quality, based on the participation of al its<br />

members and aiming at long-term succes through customer<br />

satisfaction, and benefits to al members of OnTime and to the<br />

industry.<br />

Bases on the ISO 9000, OnTime's<br />

Quality Management Team is<br />

implementing a uniform system<br />

for asesing the quality control<br />

and management of equipment<br />

and material suppliers. It<br />

is focused on the quality<br />

sysystems and management practices of the suppliers in support of<br />

delivering qualified material.<br />

STEP 1<br />

STEP 2<br />

Incoming Quality Control by<br />

QC Management checks are<br />

caried out on al products at<br />

OnTime's 2 mother warehouse.<br />

Al the IQC set-ups are<br />

equipped with state-of-the-art<br />

Testing Instruments & Software<br />

ToTools. A team of qualified engineers and technicians are responsible<br />

for the required Test & Inspection activities.<br />

STEP 3<br />

On-Site Inspection by Manufacturing<br />

Management of a<br />

part during production to<br />

detect erors. Erors that are<br />

detected early may alow the<br />

part to be reworked or<br />

prevented from continuing<br />

ththrough the manufacturing proces.<br />

STEP 4<br />

In Proces Inspection by<br />

Engineering & Technician<br />

Management wil verify and<br />

document that al applicable<br />

specifications and requirements<br />

pertaining to OnTime's<br />

product are stable and<br />

co continue to meet specifications and requirements through out the<br />

production run. Approval to continue manufacturing parts with the<br />

proces being monitored wil be given when in proces inspection<br />

indicates al contract requirements continue to be satisfied.<br />

STEP 5<br />

Additionaly, the In Proces<br />

Inspection by QC Management<br />

wil be to ensure that<br />

basic requirements continue to<br />

be met and documented as<br />

required by the customer<br />

contract specific to OnTime's<br />

reresponsibility to provide control over the proces, provide objective<br />

evidence of product conformance to specification and continued<br />

efectivenes of the quality management system.<br />

STEP 6<br />

The Quality Inspection by<br />

Warehouse Management is to<br />

determine if the products<br />

meets the specifications and<br />

drawing requirements of the<br />

purchase order. Documents<br />

are prepared to notify Purchasining<br />

and Inventory Control as to the status of the material.<br />

STEP 7<br />

Before delivering the shipment,<br />

the purchase order related<br />

products are required to<br />

conduct a Pre-Delivery Inspection.<br />

Sample checks of the<br />

shipment wil always take place<br />

to discover in-house damage,<br />

mi mising, incomplete or not operating properly.<br />

aaaaaaa