Introduction By The Managing Member - Puma

Introduction By The Managing Member - Puma

Introduction By The Managing Member - Puma

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

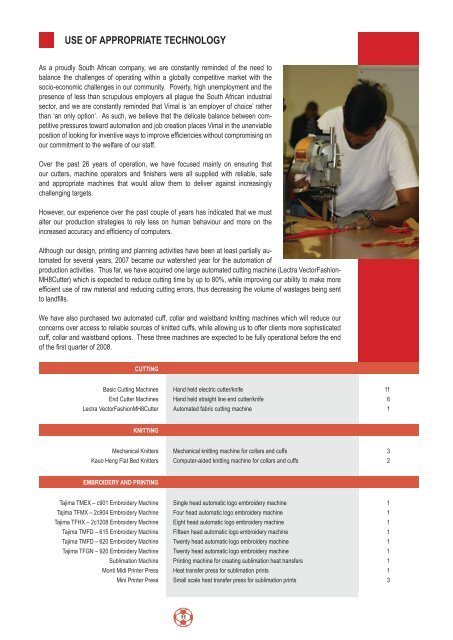

USE OF APPROPRIATE TECHNOLOGY<br />

As a proudly South African company, we are constantly reminded of the need to<br />

balance the challenges of operating within a globally competitive market with the<br />

socio-economic challenges in our community. Poverty, high unemployment and the<br />

presence of less than scrupulous employers all plague the South African industrial<br />

sector, and we are constantly reminded that Vimal is ‘an employer of choice’ rather<br />

than ‘an only option’. As such, we believe that the delicate balance between competitive<br />

pressures toward automation and job creation places Vimal in the unenviable<br />

position of looking for inventive ways to improve efficiencies without compromising on<br />

our commitment to the welfare of our staff.<br />

Over the past 26 years of operation, we have focused mainly on ensuring that<br />

our cutters, machine operators and finishers were all supplied with reliable, safe<br />

and appropriate machines that would allow them to deliver against increasingly<br />

challenging targets.<br />

However, our experience over the past couple of years has indicated that we must<br />

alter our production strategies to rely less on human behaviour and more on the<br />

increased accuracy and efficiency of computers.<br />

Although our design, printing and planning activities have been at least partially automated<br />

for several years, 2007 became our watershed year for the automation of<br />

production activities. Thus far, we have acquired one large automated cutting machine (Lectra VectorFashion-<br />

MH8Cutter) which is expected to reduce cutting time by up to 80%, while improving our ability to make more<br />

efficient use of raw material and reducing cutting errors, thus decreasing the volume of wastages being sent<br />

to landfills.<br />

We have also purchased two automated cuff, collar and waistband knitting machines which will reduce our<br />

concerns over access to reliable sources of knitted cuffs, while allowing us to offer clients more sophisticated<br />

cuff, collar and waistband options. <strong>The</strong>se three machines are expected to be fully operational before the end<br />

of the first quarter of 2008.<br />

CUTTING<br />

Basic Cutting Machines<br />

End Cutter Machines<br />

Lectra VectorFashionMH8Cutter<br />

KNITTING<br />

Mechanical Knitters<br />

Kauo Heng Flat Bed Knitters<br />

EMBROIDERY AND PRINTING<br />

Tajima TMEX – c901 Embroidery Machine<br />

Tajima TFMX – 2c904 Embroidery Machine<br />

Tajima TFHX – 2c1208 Embroidery Machine<br />

Tajima TMFD – 615 Embroidery Machine<br />

Tajima TMFD – 620 Embroidery Machine<br />

Tajima TFGN – 920 Embroidery Machine<br />

Sublimation Machine<br />

Monti Midi Printer Press<br />

Mini Printer Press<br />

Hand held electric cutter/knife<br />

Hand held straight line end cutter/knife<br />

Automated fabric cutting machine<br />

Mechanical knitting machine for collars and cuffs<br />

Computer-aided knitting machine for collars and cuffs<br />

Single head automatic logo embroidery machine<br />

Four head automatic logo embroidery machine<br />

Eight head automatic logo embroidery machine<br />

Fifteen head automatic logo embroidery machine<br />

Twenty head automatic logo embroidery machine<br />

Twenty head automatic logo embroidery machine<br />

Printing machine for creating sublimation heat transfers<br />

Heat transfer press for sublimation prints<br />

Small scale heat transfer press for sublimation prints<br />

11<br />

11<br />

6<br />

1<br />

3<br />

2<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

3