A3581 Gems Eng Pressure 2004

A3581 Gems Eng Pressure 2004

A3581 Gems Eng Pressure 2004

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

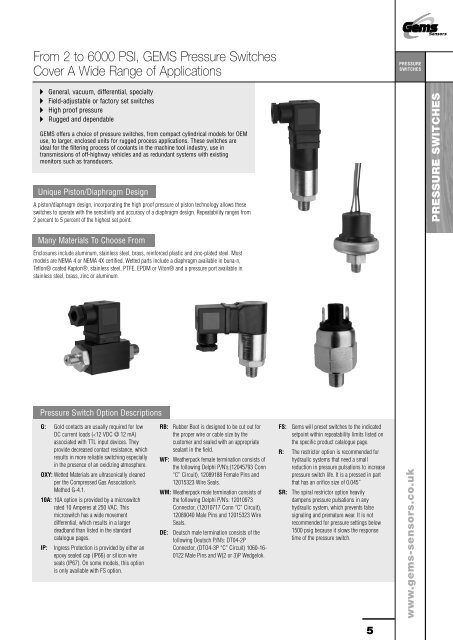

From 2 to 6000 PSI, GEMS <strong>Pressure</strong> Switches<br />

Cover A Wide Range of Applications<br />

General, vacuum, differential, specialty<br />

Field-adjustable or factory set switches<br />

High proof pressure<br />

Rugged and dependable<br />

GEMS offers a choice of pressure switches, from compact cylindrical models for OEM<br />

use, to larger, enclosed units for rugged process applications. These switches are<br />

ideal for the filtering process of coolants in the machine tool industry, use in<br />

transmissions of off-highway vehicles and as redundant systems with existing<br />

monitors such as transducers.<br />

Unique Piston/Diaphragm Design<br />

A piston/diaphragm design, incorporating the high proof pressure of piston technology allows these<br />

switches to operate with the sensitivity and accuracy of a diaphragm design. Repeatability ranges from<br />

2 percent to 5 percent of the highest set point.<br />

Many Materials To Choose From<br />

Enclosures include aluminum, stainless steel, brass, reinforced plastic and zinc-plated steel. Most<br />

models are NEMA 4 or NEMA 4X certified. Wetted parts include a diaphragm available in buna-n,<br />

Teflon® coated Kapton®, stainless steel, PTFE, EPDM or Viton® and a pressure port available in<br />

stainless steel, brass, zinc or aluminum.<br />

<strong>Pressure</strong> Switch Option Descriptions<br />

G: Gold contacts are usually required for low<br />

DC current loads (