co2 emissions from cement production - IPCC - Task Force on ...

co2 emissions from cement production - IPCC - Task Force on ...

co2 emissions from cement production - IPCC - Task Force on ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Background Paper<br />

1 INTRODUCTION<br />

1.1 Nature, magnitude, and distributi<strong>on</strong> of source<br />

Overview of Cement Producti<strong>on</strong><br />

Cement is an important c<strong>on</strong>structi<strong>on</strong> ingredient around the world, and as a result, <str<strong>on</strong>g>cement</str<strong>on</strong>g> <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> is a<br />

significant source of global carb<strong>on</strong> dioxide (CO2 ) <str<strong>on</strong>g>emissi<strong>on</strong>s</str<strong>on</strong>g>, making up approximately 2.4 percent of global<br />

CO2 <str<strong>on</strong>g>emissi<strong>on</strong>s</str<strong>on</strong>g> <str<strong>on</strong>g>from</str<strong>on</strong>g> industrial and energy sources (Marland et al., 1989). Cement is produced in large, capitalintensive<br />

<str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> plants generally located near limest<strong>on</strong>e quarries or other raw carb<strong>on</strong>ate mineral sources as<br />

these sources are the principal raw materials used in the <str<strong>on</strong>g>cement</str<strong>on</strong>g> <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> process. Because the <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g><br />

plants are expensive, the number of plants in a country is generally limited (less than 100). Carb<strong>on</strong> dioxide is<br />

emitted as a by-product of clinker <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g>, an intermediate product in <str<strong>on</strong>g>cement</str<strong>on</strong>g> manufacture, in which calcium<br />

carb<strong>on</strong>ate (CaCO3) is calcinated and c<strong>on</strong>verted to lime (CaO), the primary comp<strong>on</strong>ent of <str<strong>on</strong>g>cement</str<strong>on</strong>g>. CO2 is also<br />

emitted during <str<strong>on</strong>g>cement</str<strong>on</strong>g> <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> by fossil fuel combusti<strong>on</strong>. However, the CO2 <str<strong>on</strong>g>from</str<strong>on</strong>g> fossil fuels is specifically<br />

accounted for in emissi<strong>on</strong> estimates for fossil fuels.<br />

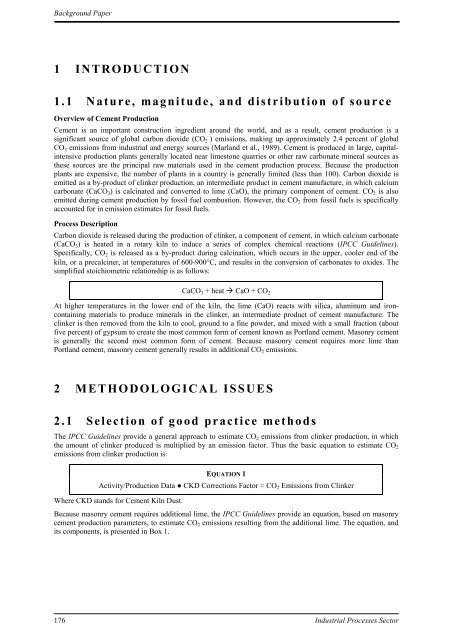

Process Descripti<strong>on</strong><br />

Carb<strong>on</strong> dioxide is released during the <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> of clinker, a comp<strong>on</strong>ent of <str<strong>on</strong>g>cement</str<strong>on</strong>g>, in which calcium carb<strong>on</strong>ate<br />

(CaCO3) is heated in a rotary kiln to induce a series of complex chemical reacti<strong>on</strong>s (<str<strong>on</strong>g>IPCC</str<strong>on</strong>g> Guidelines).<br />

Specifically, CO2 is released as a by-product during calcinati<strong>on</strong>, which occurs in the upper, cooler end of the<br />

kiln, or a precalciner, at temperatures of 600-900°C, and results in the c<strong>on</strong>versi<strong>on</strong> of carb<strong>on</strong>ates to oxides. The<br />

simplified stoichiometric relati<strong>on</strong>ship is as follows:<br />

176<br />

CaCO3 + heat CaO + CO2<br />

At higher temperatures in the lower end of the kiln, the lime (CaO) reacts with silica, aluminum and ir<strong>on</strong>c<strong>on</strong>taining<br />

materials to produce minerals in the clinker, an intermediate product of <str<strong>on</strong>g>cement</str<strong>on</strong>g> manufacture. The<br />

clinker is then removed <str<strong>on</strong>g>from</str<strong>on</strong>g> the kiln to cool, ground to a fine powder, and mixed with a small fracti<strong>on</strong> (about<br />

five percent) of gypsum to create the most comm<strong>on</strong> form of <str<strong>on</strong>g>cement</str<strong>on</strong>g> known as Portland <str<strong>on</strong>g>cement</str<strong>on</strong>g>. Mas<strong>on</strong>ry <str<strong>on</strong>g>cement</str<strong>on</strong>g><br />

is generally the sec<strong>on</strong>d most comm<strong>on</strong> form of <str<strong>on</strong>g>cement</str<strong>on</strong>g>. Because mas<strong>on</strong>ry <str<strong>on</strong>g>cement</str<strong>on</strong>g> requires more lime than<br />

Portland <str<strong>on</strong>g>cement</str<strong>on</strong>g>, mas<strong>on</strong>ry <str<strong>on</strong>g>cement</str<strong>on</strong>g> generally results in additi<strong>on</strong>al CO2 <str<strong>on</strong>g>emissi<strong>on</strong>s</str<strong>on</strong>g>.<br />

2 METHODOLOGICAL ISSUES<br />

2.1 Selecti<strong>on</strong> of good practice methods<br />

The <str<strong>on</strong>g>IPCC</str<strong>on</strong>g> Guidelines provide a general approach to estimate CO2 <str<strong>on</strong>g>emissi<strong>on</strong>s</str<strong>on</strong>g> <str<strong>on</strong>g>from</str<strong>on</strong>g> clinker <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g>, in which<br />

the amount of clinker produced is multiplied by an emissi<strong>on</strong> factor. Thus the basic equati<strong>on</strong> to estimate CO2<br />

<str<strong>on</strong>g>emissi<strong>on</strong>s</str<strong>on</strong>g> <str<strong>on</strong>g>from</str<strong>on</strong>g> clinker <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> is:<br />

EQUATION 1<br />

Activity/Producti<strong>on</strong> Data ● CKD Correcti<strong>on</strong>s Factor = CO2 Emissi<strong>on</strong>s <str<strong>on</strong>g>from</str<strong>on</strong>g> Clinker<br />

Where CKD stands for Cement Kiln Dust.<br />

Because mas<strong>on</strong>ry <str<strong>on</strong>g>cement</str<strong>on</strong>g> requires additi<strong>on</strong>al lime, the <str<strong>on</strong>g>IPCC</str<strong>on</strong>g> Guidelines provide an equati<strong>on</strong>, based <strong>on</strong> mas<strong>on</strong>ry<br />

<str<strong>on</strong>g>cement</str<strong>on</strong>g> <str<strong>on</strong>g>producti<strong>on</strong></str<strong>on</strong>g> parameters, to estimate CO2 <str<strong>on</strong>g>emissi<strong>on</strong>s</str<strong>on</strong>g> resulting <str<strong>on</strong>g>from</str<strong>on</strong>g> the additi<strong>on</strong>al lime. The equati<strong>on</strong>, and<br />

its comp<strong>on</strong>ents, is presented in Box 1.<br />

Industrial Processes Sector