SLuDGE bLANKET CLARIFIER FOR WATER TREATMENT ...

SLuDGE bLANKET CLARIFIER FOR WATER TREATMENT ...

SLuDGE bLANKET CLARIFIER FOR WATER TREATMENT ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

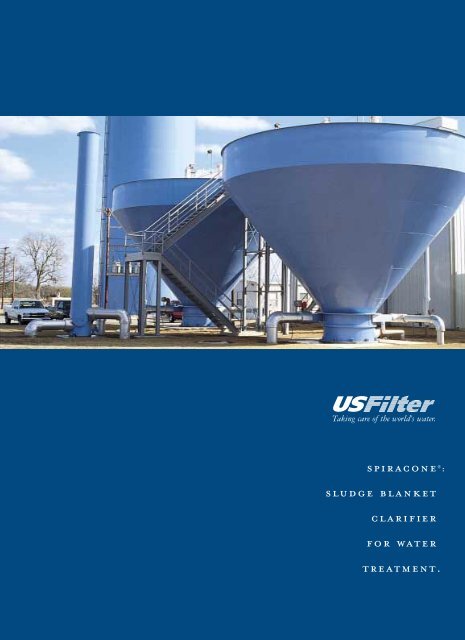

Taking care of the world’s water.<br />

spiracone ® :<br />

sludge blanket<br />

clarifier<br />

for water<br />

treatment.

SPIRACONE OPERATION<br />

APPLICATIONS<br />

• Clarification<br />

• Color Removal<br />

• Iron Removal<br />

• Softening<br />

• Wastewater Treatment<br />

• Phosphate Reduction<br />

• Heavy Metals<br />

USFilter’s General Filter SPIRACONE is an upflow sludge blanket clarifier that combines<br />

mixing, flocculation, and sedimentation in a single treatment basin for maximum treated<br />

water production in minimal space. Raw water and chemicals are hydraulically mixed and then<br />

pass upward through distinct zones for reaction-flocculation, clarification, and sludge removal.<br />

Hydraulic mixing eliminates mechanical mixers, while the conical shape eliminates scrapers.<br />

The unit’s compact size reduces cost by minimizing land requirements, and the mixerless and<br />

scraperless design minimizes maintenance.<br />

Raw water and chemicals are introduced<br />

at the base of a SPIRACONE. The<br />

intricate design of the inlet structure<br />

aids in directing the influent flow in<br />

an upward expanding spiral without<br />

disturbing the sludge blanket. The<br />

velocity of the influent flow decreases as<br />

it progresses up through the increasing<br />

cross-sectional area in the SPIRACONE.<br />

Turbulence between the high velocity<br />

influent flow and the slower rising<br />

water forms a mixing zone.<br />

As the flow progresses up through<br />

the unit, the rise rate becomes less than<br />

the settling velocity of the precipitating<br />

solids (floc). At this point, a sludge<br />

blanket forms which acts as a filter and<br />

catalyst, collecting small particles of<br />

sludge. Chemicals are given intimate<br />

Velocity Baffle<br />

Controller<br />

Effluent<br />

Inlet<br />

Start-up Jet<br />

Grit Blowdown<br />

Concrete Base<br />

contact with turbidity, solids and/or<br />

hardness in the water and the chemical<br />

reactions are forced to completion.<br />

Settling sludge concentrates in the<br />

zero-velocity zone of the sludge hopper<br />

and is intermittently drawn off. The<br />

elevation of the sludge hopper is<br />

adjustable to maximize process efficiency.<br />

Heavier solids are removed from the<br />

unit through the grit blowdown connection.<br />

A start-up jet is provided to<br />

assist in re-suspending settled solids after<br />

a unit shutdown.<br />

After rising through the clarification<br />

zone, the high quality treated water<br />

exits through the perimeter effluent<br />

launder and proceeds to the rest of the<br />

treatment plant.<br />

Launder<br />

Sludge Blanket<br />

Adjustable Sludge<br />

Hopper<br />

Mixing Zone<br />

Sludge Blowdown

SPIRACONE APPLICATIONS<br />

PROVIDING QUALITY <strong>WATER</strong><br />

SPIRACONE PILOT PLANT<br />

Edmond, OK, four 47’ diameter units, treating<br />

12 MGD of surface water.<br />

Wills Point, TX, two 36’ 6’’ diameter units,<br />

treating 2 MGD of surface water.<br />

USFilter’s General Filter SPIRACONE<br />

pilot unit can be installed at a specific<br />

location alone or in conjunction with<br />

other General Filter pilot units to<br />

finalize equipment or plant design.<br />

The self-contained unit is ideal to<br />

verify process design, to evaluate full<br />

scale operation, or to estimate ancillary<br />

equipment requirements.<br />

Also available are pilot plants for<br />

iron and manganese removal; a variety<br />

of MULTIWASH filter plants; Aerator<br />

for removal of dissolved gases; CON-<br />

TRAFLO Solids Contact Reactor; and<br />

SURF for treating surface water. In<br />

addition, we have an instrumentation<br />

skid and chemical feed skid available to<br />

help with your equipment design.<br />

TURBIDITY (NTU)<br />

TURBIDITY (NTU)<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

16.0<br />

14.0<br />

12.0<br />

10.0<br />

8.0<br />

6.0<br />

4.0<br />

2.0<br />

EDMOND, OK<br />

OPERATING DATA<br />

Raw Water SPIRACONE Effluent<br />

JUN JUL AUG SEP<br />

DATE<br />

OCT NOV DEC<br />

0.0<br />

APRIL 1<br />

WILLS POINT, TEXAS<br />

OPERATING DATA<br />

Raw Water SPIRACONE Effluent<br />

DATE<br />

MAY 1

If it’s in the water, our engineered processes and equipment can take it out, economically<br />

and dependably. Our comprehensive line includes solutions to simple and complex water<br />

treatment and conditioning needs, all backed by working installations and years of<br />

experience. Our line includes:<br />

■ Adsorption Clarifiers ®<br />

■ CONTRAFLO ® solids contact clarifiers<br />

■ SPIRACONE ® sludge blanket clarifiers<br />

■ Sludge Sucker sludge removal system<br />

■ Sludge thickeners<br />

■ Vertical and horizontal pressure filters<br />

■ Aerators<br />

■ AERALATER ® packaged treatment<br />

Memcor CMF Microfiltration system<br />

Microfloc Tridentsystem<br />

USFilter products and processes are<br />

protected by U.S. Patents, several<br />

foreign patents and other patents<br />

pending.<br />

SCG1 0599<br />

OTHER <strong>WATER</strong> <strong>TREATMENT</strong> PRODUCTS<br />

■ Microfloc ® Trident ® packaged water<br />

treatment<br />

■ MULTIWASH ® Filtration Process<br />

■ Gravity filtration equipment<br />

■ MULTICRETE II monolithic underdrain<br />

system<br />

■ ESSD filter washtroughs and launder<br />

systems<br />

■ Memcor CMF Microfiltration System<br />

CONTRAFLO clarifiers<br />

Ballasted Flocculation Clarifiers<br />

Taking care of the world’s water.<br />

Memcor, Microfloc<br />

General Filter Products<br />

600 Arrasmith Trail<br />

Ames, IA 50010<br />

515.232.4121 phone<br />

515.232.2571 fax<br />

441 Main Street<br />

P.O. Box 36<br />

Sturbridge, MA 01566<br />

508.347.7344 phone<br />

508.347.7049 fax<br />

1104 Kenilworth Drive<br />

Fifth Floor<br />

Towson, MD 21204<br />

410.307.6540 phone<br />

410.307.6542 fax<br />

http://www.usfilter.com<br />

© 1999 United States Filter Corporation