download complete PDF catalog - Maryland Metrics

download complete PDF catalog - Maryland Metrics

download complete PDF catalog - Maryland Metrics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

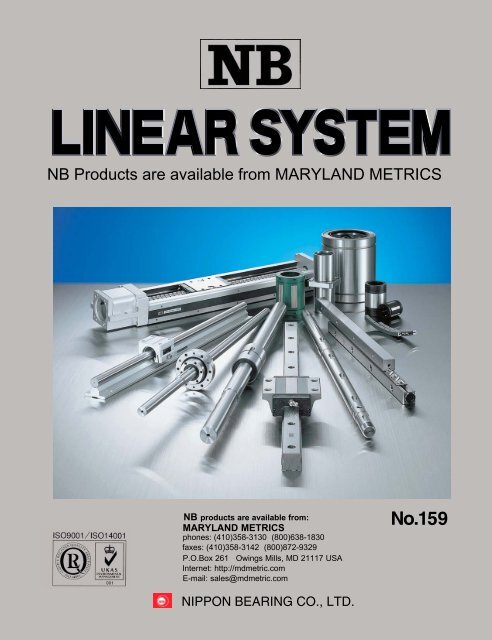

NB Products are available from MARYLAND METRICS<br />

NB products are available from:<br />

MARYLAND METRICS<br />

phones: (410)358-3130 (800)638-1830<br />

faxes: (410)358-3142 (800)872-9329<br />

P.O.Box 261 Owings Mills, MD 21117 USA<br />

Internet: http://mdmetric.com<br />

E-mail: sales@mdmetric.com<br />

NIPPON BEARING CO., LTD.<br />

No.159

LINEAR SYSTEM<br />

Nippon Bearing Co., Ltd.

Eng- 112<br />

<br />

Tech- 17<br />

INDEX- 18<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

A-181<br />

B-145<br />

C-123<br />

D-1120<br />

E-146<br />

F-123<br />

G-119<br />

H-168<br />

I-155<br />

J-17

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SLIDE GUIDE<br />

SEBS-B/BY P.A-26<br />

SEBS-B-N/BY-N P.A-26<br />

SEB-A/AY P.A-30<br />

SEB-A-N/AY-N P.A-30<br />

SER-WA P.A-40<br />

SER-WA-N P.A-40<br />

SEBS-BM/BYM P.A-26<br />

SEBS-BM-N/BYM-N P.A-26<br />

SEB-WA/WAY P.A-32<br />

SEB-WA-N/WAY-N P.A-32<br />

SEBS-WB/WBY P.A-28<br />

SEBS-WB-N/WBY-N P.A-28<br />

SER-A P.A-38<br />

SER-A-N P.A-38<br />

GL-F P.A-48 GL-TF P.A-50 GL-HTF P.A-52

GL-E P.A-54 GL-TE P.A-56<br />

SGL-E P.A-70<br />

<br />

GL-HTE P.A-58<br />

SGL-F P.A-64 SGL-TF P.A-66 SGL-HTF P.A-68<br />

SGW-TE P.A-80<br />

SGL-TE P.A-72 SGL-HTE P.A-74<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

BALL SPLINE<br />

SSP/SSPS P.B-16 SSPM P.B-18 SSPF/SSPFS P.B-20<br />

SSPT P.B-22 SPA P.B-24 SPA-W P.B-26<br />

SSPB P.B-28 SSP-S P.B-30 SSP-C P.B-31<br />

SPR P.B-38 SPLFS P.B-44

TOPBALL <br />

TK P.C-8<br />

TK-OP P.C-8<br />

TKA P.C-12<br />

TKA-W P.C-13<br />

TWA P.C-18<br />

TWA-W P.C-19<br />

PRODUCTS<br />

TW P.C-10<br />

TW-OP P.C-10<br />

TKE P.C-14<br />

TKE-W P.C-15<br />

TWJ P.C-20<br />

TWJ-W P.C-21<br />

<br />

TKD P.C-16<br />

TKD-W P.C-17<br />

TWD P.C-22<br />

TWD-W P.C-23<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SLIDE BUSH<br />

GM P.D- 12<br />

GW P.D-120<br />

SM P.D-26<br />

KB P.D-76<br />

SW P.D-98<br />

SM-W P.D- 32<br />

KB-W P.D- 82<br />

SW-W P.D-104<br />

SLIDE BUSH (Flange Type)<br />

GM-W P.D-13<br />

SM-AJ P.D- 28<br />

KB-AJ P.D- 78<br />

SW-AJ P.D-100<br />

SM-OP P.D- 30<br />

KB-OP P.D- 80<br />

SW-OP P.D-102<br />

GMF-W P.D-14 GMK-W P.D-16 GMT-W P.D-18

GMF-W-E P.D-20<br />

SMF P.D- 34<br />

KBF P.D- 84<br />

SWF P.D-106<br />

SMF-W P.D- 46<br />

KBF-W P.D- 90<br />

SWF-W P.D-112<br />

GMK-W-E P.D-22<br />

SMK P.D- 36<br />

KBK P.D- 86<br />

SWK P.D-108<br />

SMK-W P.D- 48<br />

KBK-W P.D- 92<br />

SWK-W P.D-114<br />

<br />

GMT-W-E P.D-24<br />

SMT P.D- 38<br />

KBT P.D- 88<br />

SWT P.D-110<br />

SMF-E P.D-40 SMK-E P.D-42 SMT-E P.D-44<br />

SMT-W P.D-50<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SLIDE BUSH (Flange Type)<br />

SMFC P.D- 52<br />

KBFC P.D- 94<br />

SWFC P.D-116<br />

SMKC P.D- 54<br />

KBKC P.D- 96<br />

SWKC P.D-118<br />

SMTC P.D-56<br />

SMF-W-E P.D-58 SMK-W-E P.D-60 SMT-W-E P.D-62<br />

TRF P.D-64 TRK P.D-66 TRFC P.D-68<br />

TRKC P.D-70 TRF-E P.D-72 TRK-E P.D-74

SLIDE UNIT<br />

<br />

SMA P.E-8 SMA-W P.E-10 AK P.E-12<br />

AK-W P.E-14 SMB P.E-16 SMP P.E-18<br />

SMJ P.E-20 SME P.E-22 SME-W P.E-24<br />

SMD P.E-26 RB P.E-28<br />

RBW P.E-44<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SLIDE UNIT<br />

SWA P.E-38 SWJ P.E-40 SWD P.E-42<br />

SH-A P.E-29<br />

WH-A P.E-45<br />

SA P.E-32<br />

WA P.E-46<br />

SH P.E-30 SHF/SHF-FC P.E-31<br />

CE P.E-34 CD P.E-36

STROKE BUSH, SLIDE ROTARY BUSH<br />

<br />

SR P.F-4 SR-UU P.F-5 SR-B P.F-6<br />

SR-BUU P.F-7<br />

SMA-R P.F-16<br />

AK-RW P.F-19<br />

SRE P.F-12<br />

SMA-RW P.F-17<br />

SMP-R P.F-20<br />

SREK P.F-14<br />

AK-R P.F-18<br />

RK P.F-23<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SLIDE SHAFT<br />

SN P.G-6 SNS P.G-7 SNT P.G-8<br />

SNB/SNSB P.G-9<br />

SNW/SNWS P.G-10/11<br />

SNW-PD/SNWS-PD P.G-12/13<br />

SLIDE WAY, SLIDE TABLE, GONIO WAY<br />

NV P.H-8<br />

NVT P.H-10<br />

SV P.H-18<br />

SVW P.H-26 SVT P.H-34 SYT P.H-40

SYT-D P.H-44 SYBS P.H-52 RVF P.G-60<br />

RV P.H-66<br />

ACTUATOR<br />

BG P.I-1<br />

SLIDE SCREW<br />

SS P.J-7<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

INDEX<br />

AK Slide Unit : Compact Block Type E- 12<br />

AK-G Slide Unit : Compact Block Type E- 12<br />

AK-GW Slide Unit : Compact Block Double-Wide Type E- 14<br />

AK-R Slide Rotary Unit : Compact Block Type F- 18<br />

AK-RW Slide Rotary Unit : Compact Block Double-Wide Type F- 19<br />

AK-W Slide Unit : Compact Block Double-Wide Type E- 12<br />

AKS Slide Unit : Compact Block Type, Anticorrosion E- 10<br />

AKS-G Slide Unit : Compact Block Type, Anticorrosion E- 10<br />

AKS-GW Slide Unit : Compact Block Double-Wide Type, Anticorrosion E- 12<br />

AKS-W Slide Unit : Compact Block Double-Wide Type, Anticorrosion E- 12<br />

BG Actuator : Integrated Guide and Ball Screw System I- 1<br />

BT Slide Way : SV Exclusive Mounting Bolt H- 7,16<br />

CD Assembled Unit : Clearance Adjustable Type E- 36<br />

CDS Assembled Unit : Clearance Adjustable Type, Anticorrosion E- 36<br />

CE Assembled Unit : Non-Clearance Adjustable Type E- 34<br />

CES Assembled Unit : Non-Clearance Adjustable Type, Anticorrosion E- 34<br />

CR Gonio Way : Curved Roller Cage H- 68<br />

F Slide Guide : Rail Plug A- 15<br />

FLM Slide Bush : Felt Seal D- 11<br />

FP Ball Spline : Lock Plate B- 13<br />

GL-E Slide Guide : High Rigidity Flange Type (Short Configuration) A- 54<br />

GL-F Slide Guide : High Rigidity Non-Flange Type (Short Configuration) A- 48<br />

GL-HTE Slide Guide : High Rigidity Flange Type A- 58<br />

GL-HTF Slide Guide : High Rigidity Non-Flange Type A- 52<br />

GL-TE Slide Guide : High Rigidity Flange Type A- 56<br />

GL-TF Slide Guide : High Rigidity Non-Flange Type A- 50<br />

GM Slide Bush : Light Weight Type D- 12<br />

GM-W Slide Bush : Light Weight Double-Wide Type D- 13<br />

GMF-W Slide Bush : Light Weight Round Flange Double-Wide Type D- 14<br />

GMF-W-E Slide Bush : Round Flange Double-Wide Pilot End Type C- 20<br />

GMK-W Slide Bush : Light Weight Square Flange Double-Wide Type D- 16<br />

GMK-W-E Slide Bush : Square Flange Double-Wide Pilot End Type C- 22<br />

GMT-W Slide Bush : Light Weight Two Side Cut Double-Wide Type D- 18<br />

GMT-W-E Slide Bush : Two Side Cut Double-Wide Flange Pilot End Type C- 24<br />

GW Slide Bush (Inch Standard) : Light Weight Type D-120<br />

KB Slide Bush (Euro Standard) : Standard Type D- 76<br />

KB-AJ Slide Bush (Euro Standard) : Clearance Adjustable Type D- 78<br />

KB-G Slide Bush (Euro Standard) : Standard Type D- 76<br />

KB-G-AJ Slide Bush (Euro Standard) : Clearance Adjustable Type D- 78<br />

KB-G-OP Slide Bush (Euro Standard) : Open Type D- 80<br />

KB-GW Slide Bush (Euro Standard) : Double-Wide Type D- 82<br />

KB-OP Slide Bush (Euro Standard) : Open Type D- 80<br />

KB-W Slide Bush (Euro Standard) : Double-Wide Type D- 82<br />

KBF Slide Bush (Euro Standard) : Round Flange Type D- 84<br />

KBF-G Slide Bush (Euro Standard) : Round Flange Type D- 84<br />

INDEX-1

KBF-GW Slide Bush (Euro Standard) : Round Flange Double-Wide Type D- 90<br />

KBF-W Slide Bush (Euro Standard) : Round Flange Double-Wide Type D- 90<br />

KBFC Slide Bush (Euro Standard) : Center Mount Round Flange Type D- 94<br />

KBFC-G Slide Bush (Euro Standard) : Center Mount Round Flange Type D- 94<br />

KBK Slide Bush (Euro Standard) : Square Flange Type D- 86<br />

KBK-G Slide Bush (Euro Standard) : Square Flange Type D- 86<br />

KBK-GW Slide Bush (Euro Standard) : Square Flange Double-Wide Type D- 92<br />

KBK-W Slide Bush (Euro Standard) : Square Flange Double-Wide Type D- 92<br />

KBKC Slide Bush (Euro Standard) : Center Mount Square Flange Type D- 96<br />

KBKC-G Slide Bush (Euro Standard) : Center Mount Square Flange Type D- 96<br />

KBS Slide Bush (Euro Standard) : Standard Type, Anticorrosion D- 76<br />

KBS-AJ Slide Bush (Euro Standard) : Clearance Adjustable Type, Anticorrosion D- 78<br />

KBS-G Slide Bush (Euro Standard) : Standard Type, Anticorrosion D- 76<br />

KBS-G-AJ Slide Bush (Euro Standard) : Clearance Adjustable Type, Anticorrosion D- 78<br />

KBS-G-OP Slide Bush (Euro Standard) : Open Type, Anticorrosion D- 80<br />

KBS-GW Slide Bush (Euro Standard) : Double-Wide Type, Anticorrosion D- 82<br />

KBS-OP Slide Bush (Euro Standard) : Open Type, Anticorrosion D- 80<br />

KBS-W Slide Bush (Euro Standard) : Double-Wide Type, Anticorrosion D- 82<br />

KBSF Slide Bush (Euro Standard) : Round Flange Type, Anticorrosion D- 84<br />

KBSF-G Slide Bush (Euro Standard) : Round Flange Type, Anticorrosion D- 84<br />

KBSF-GW Slide Bush (Euro Standard) : Round Flange Double-Wide Type, Anticorrosion D- 90<br />

KBSF-W Slide Bush (Euro Standard) : Round Flange Double-Wide Type, Anticorrosion D- 90<br />

KBSFC Slide Bush (Euro Standard) : Center Mount Round Flange Type, Anticorrosion D- 94<br />

KBSFC-G Slide Bush (Euro Standard) : Center Mount Round Flange Type, Anticorrosion D- 94<br />

KBSK Slide Bush (Euro Standard) : Square Flange Type, Anticorrosion D- 86<br />

KBSK-G Slide Bush (Euro Standard) : Square Flange Type, Anticorrosion D- 86<br />

KBSK-GW Slide Bush (Euro Standard) : Square Flange Double-Wide Type, Anticorrosion D- 92<br />

KBSK-W Slide Bush (Euro Standard) : Square Flange Double-Wide Type, Anticorrosion D- 92<br />

KBSKC Slide Bush (Euro Standard) : Center Mount Square Flange Type, Anticorrosion D- 96<br />

KBSKC-G Slide Bush (Euro Standard) : Center Mount Square Flange Type, Anticorrosion D- 96<br />

KBST Slide Bush (Euro Standard) : Two Side Cut Flange Type, Anticorrosion D- 88<br />

KBST-G Slide Bush (Euro Standard) : Two Side Cut Flange Type, Anticorrosion D- 88<br />

KBT Slide Bush (Euro Standard) : Two Side Cut Flange Type D- 88<br />

KBT-G Slide Bush (Euro Standard) : Two Side Cut Flange Type D- 88<br />

KGF-Grease Low Dust-generation Eng- 22<br />

KGL-Grease Low Dust-generation Eng- 20<br />

KGU-Grease Low Dust-generation Eng- 20<br />

K-Grease Low Dust-generation Eng- 22<br />

LP Ball Spline : Lock Plate B- 13<br />

NV Slide Way : STUDROLLER System H- 8<br />

NVT Slide Way : STUDROLLER System H- 10<br />

R Slide Way : Roller Cage H- 29<br />

RA Slide Way : Aluminum Roller Cage H- 29<br />

RAS Slide Way : Aluminum Roller Cage, Anticorrosion H- 29<br />

RB Slide Unit : Resin Block Type E- 28<br />

RBW Slide Unit (Inch Standard) : Resin Block Type E- 44<br />

RK Slide Rotary Bush F- 23<br />

RS Slide Way : Roller Cage, Anticorrosion H- 29<br />

RV Gonio Way H- 66<br />

RVF Gonio Way:Flat Rail Type H- 60<br />

INDEX-2<br />

<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SA Slide Unit : Shaft Support Rail E- 32<br />

SEB-A Slide Guide : Miniature Type A- 30<br />

SEB-A-N Slide Guide : Miniature Type w/Tapped Hole Rail A- 30<br />

SEB-AY Slide Guide : Miniature Long Type A- 30<br />

SEB-AY-N Slide Guide : Miniature Long Type w/Tapped Hole Rail A- 30<br />

SEB-WA Slide Guide : Miniature Wide Type A- 32<br />

SEB-WA-N Slide Guide : Miniature Wide Type w/Tapped Hole Rail A- 32<br />

SEB-WAY Slide Guide : Miniature Wide and Long Type A- 32<br />

SEB-WAY-N Slide Guide : Miniature Wide and Long Type w/Tapped Hole Rail A- 32<br />

SEB-WD Slide Guide : Miniature Wide Type A- 32<br />

SEB-WD-N Slide Guide : Miniature Wide Type w/Tapped Hole Rail A- 32<br />

SEBS-A Slide Guide : Miniature Type, Anticorrosion A- 30<br />

SEBS-A-N Slide Guide : Miniature Type w/Tapped Hole Rail, Anticorrosion A- 30<br />

SEBS-AY Slide Guide : Miniature Long Type, Anticorrosion A- 30<br />

SEBS-AY-N Slide Guide : Miniature Long Type w/Tapped Hole Rail, Anticorrosion A- 30<br />

SEBS-B Slide Guide (Retained Ball) : Miniature Type A- 26<br />

SEBS-B-N Slide Guide (Retained Ball) : Miniature Type w/Tapped Hole Rail A- 26<br />

SEBS-BM Slide Guide (Retained Ball) : Miniature All Stainless Type A- 26<br />

SEBS-BM-N Slide Guide (Retained Ball) : Miniature All Stainless Type w/Tapped Hole Rail A- 26<br />

SEBS-BY Slide Guide (Retained Ball) : Miniature Long Type A- 26<br />

SEBS-BY-N Slide Guide (Retained Ball) : Miniature Long Type w/Tapped Hole Rail A- 26<br />

SEBS-BYM Slide Guide (Retained Ball) : Miniature All Stainless Long Type A- 26<br />

SEBS-BYM-N Slide Guide (Retained Ball) : Miniature All Stainless Long Type w/Tapped Hole Rail A- 26<br />

SEBS-WA Slide Guide : Miniature Wide Type, Anticorrosion A- 32<br />

SEBS-WA-N Slide Guide : Miniature Wide Type w/Tapped Hole Rail, Anticorrosion A- 32<br />

SEBS-WAY Slide Guide : Miniature Wide and Long Type, Anticorrosion A- 32<br />

SEBS-WAY-N Slide Guide : Miniature Wide and Long Type w/Tapped Hole Rail, Anticorrosion A- 32<br />

SEBS-WB Slide Guide(Retained Ball) : Miniature Wide Type A- 28<br />

SEBS-WB-N Slide Guide(Retained Ball) : Miniature Wide Type w/Tapped Hole Rail A- 28<br />

SEBS-WBY Slide Guide(Retained Ball) : Miniature Wide Type A- 28<br />

SEBS-WBY-N Slide Guide(Retained Ball) : Miniature Long Type w/Tapped Hole Rail, Anticorrosion A- 28<br />

SEBS-WD Slide Guide : Miniature Wide Type, Anticorrosion A- 32<br />

SEBS-WD-N Slide Guide : Miniature Wide Type w/Tapped Hole Rail, Anticorrosion A- 32<br />

SER-A Slide Guide (Roller Element) : Miniature Type A- 38<br />

SER-A-N Slide Guide (Roller Element) : Miniature Type w/Tapped Hole Rail A- 38<br />

SER-WA Slide Guide (Roller Element) : Miniature Wide Type A- 40<br />

SER-WA-N Slide Guide (Roller Element) : Miniature Wide Type w/Tapped Hole Rail A- 40<br />

SERS-A Slide Guide (Roller Element) : Miniature Type, Anticorrosion A- 38<br />

SERS-A-N Slide Guide (Roller Element) : Miniature Type w/Tapped Hole Rail, Anticorrosion A- 38<br />

SERS-WA Slide Guide (Roller Element) : Miniature Wide Type, Anticorrosion A- 40<br />

SERS-WA-N Slide Guide (Roller Element) : Miniature Wide Type w/Tapped Hole Rail, Anticorrosion A- 40<br />

SGL-E Slide Guide : High Rigidity Flange Type (Short Configuration) A- 70<br />

SGL-F Slide Guide : High Rigidity Non-Flange Type (Short Configuration) A- 64<br />

SGL-HTE Slide Guide : High Rigidity Flange Type A- 74<br />

SGL-HTF Slide Guide : High Rigidity Non-Flange Type A- 68<br />

SGL-TE Slide Guide : High Rigidity Flange Type A- 72<br />

SGL-TF Slide Guide : High Rigidity Non-Flange Type A- 66<br />

SGW-TE Slide Guide : High Rigidity Wide Flange Type A- 80<br />

INDEX-3

SH Slide Unit : Shaft End Supporter E- 30<br />

SH-A Slide Unit : Aluminum Shaft End Supporter E- 29<br />

SHF Slide Unit : Shaft End Supporter Flange Type E- 31<br />

SHF-FC Slide Unit : Cast Iron E- 31<br />

SM Slide Bush : Standard Type D- 26<br />

SM-AJ Slide Bush : Clearance Adjustable Type D- 28<br />

SM-G Slide Bush : Standard Type D- 26<br />

SM-G-AJ Slide Bush : Clearance Adjustable Type D- 28<br />

SM-G-OP Slide Bush : Open Type D- 30<br />

SM-GW Slide Bush : Double-Wide Type D- 32<br />

SM-OP Slide Bush : Open Type D- 30<br />

SM-W Slide Bush : Double-Wide Type D- 32<br />

SMA Slide Unit : Block Type E- 8<br />

SMA-G Slide Unit : Block Type E- 8<br />

SMA-GW Slide Unit : Double-Wide Block Type E- 10<br />

SMA-R Slide Rotary Unit : Block Type F- 16<br />

SMA-RW Slide Rotary Unit : Block Double-Wide Type F- 17<br />

SMA-W Slide Unit : Double-Wide Block Type E- 8<br />

SMB Slide Unit : Block Type E- 16<br />

SMB-G Slide Unit : Block Type E- 16<br />

SMD Slide Unit : Clearance Adjustable Open Block Type E- 26<br />

SMD-G Slide Unit : Clearance Adjustable Open Block Type E- 26<br />

SME Slide Unit : Non-Clearance Adjustable Open Block Type E- 22<br />

SME-G Slide Unit : Non-Clearance Adjustable Open Block Type E- 22<br />

SME-GW Slide Unit : Double-Wide Open Block Type E- 24<br />

SME-W Slide Unit : Double-Wide Open Block Type E- 24<br />

SMF Slide Bush : Round Flange Type D- 34<br />

SMF-E Slide Bush : Round Flange Pilot End Type D- 40<br />

SMF-G Slide Bush : Round Flange Type D- 34<br />

SMF-G-E Slide Bush : Round Flange Pilot End Type D- 46<br />

SMF-GW Slide Bush : Round Flange Double-Wide Type D- 46<br />

SMF-GW-E Slide Bush : Round Flange Double-Wide Pilot End Type D- 58<br />

SMF-W Slide Bush : Round Flange Double-Wide Type D- 46<br />

SMF-W-E Slide Bush : Round Flange Double-Wide Pilot End Type D- 58<br />

SMFC Slide Bush : Center Mount Round Flange Type D- 52<br />

SMFC-G Slide Bush : Center Mount Round Flange Type D- 52<br />

SMJ Slide Unit : Clearance Adjustable Block Type E- 20<br />

SMJ-G Slide Unit : Clearance Adjustable Block Type E- 20<br />

SMK Slide Bush : Square Flange Type D- 36<br />

SMK-E Slide Bush : Square Flange Pilot End Type D- 42<br />

SMK-G Slide Bush : Square Flange Type D- 36<br />

SMK-G-E Slide Bush : Square Flange Pilot End Type D- 42<br />

SMK-GW Slide Bush : Square Flange Double-Wide Type D- 48<br />

SMK-GW-E Slide Bush : Square Flange Double-Wide Pilot End Type D- 60<br />

SMK-W Slide Bush : Square Flange Double-Wide Type D- 48<br />

SMK-W-E Slide Bush : Square Flange Double-Wide Pilot End Type D- 60<br />

SMKC Slide Bush : Center Mount Square Flange Type D- 54<br />

SMKC-G Slide Bush : Center Mount Square Flange Type D- 54<br />

SMP Slide Unit : Pillow Block Type E- 18<br />

SMP-G Slide Unit : Pillow Block Type E- 18<br />

SMP-R Slide Rotary Unit : Pillow Block Type F- 20<br />

SMS Slide Bush : Standard Type, Anticorrosion D- 26<br />

SMS-AJ Slide Bush : Clearance Adjustable Type, Anticorrosion D- 28<br />

INDEX-4<br />

<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SMS-G Slide Bush : Standard Type, Anticorrosion D- 26<br />

SMS-G-AJ Slide Bush : Clearance Adjustable Type, Anticorrosion D- 28<br />

SMS-G-OP Slide Bush : Open Type, Anticorrosion D- 30<br />

SMS-GW Slide Bush : Double-Wide Type, Anticorrosion D- 32<br />

SMS-OP Slide Bush : Open Type, Anticorrosion D- 30<br />

SMS-W Slide Bush : Double-Wide Type, Anticorrosion D- 32<br />

SMSA Slide Unit : Block Type, Anticorrosion E- 6<br />

SMSA-G Slide Unit : Block Type, Anticorrosion E- 6<br />

SMSA-GW Slide Unit : Double-Wide Block Type, Anticorrosion E- 8<br />

SMSA-W Slide Unit : Double-Wide Block Type, Anticorrosion E- 8<br />

SMSB Slide Unit : Block Type, Anticorrosion E- 14<br />

SMSB-G Slide Unit : Block Type, Anticorrosion E- 14<br />

SMSD Slide Unit : Clearance Adjustable Open Block Type, Anticorrosion E- 24<br />

SMSD-G Slide Unit : Clearance Adjustable Open Block Type, Anticorrosion E- 24<br />

SMSE Slide Unit : Non-Clearance Adjustable Open Block Type, Anticorrosion E- 20<br />

SMSE-G Slide Unit : Non-Clearance Adjustable Open Block Type, Anticorrosion E- 20<br />

SMSE-GW Slide Unit : Double-Wide Open Block Type, Anticorrosion E- 22<br />

SMSE-W Slide Unit : Double-Wide Open Block Type, Anticorrosion E- 22<br />

SMSF Slide Bush : Round Flange Type, Anticorrosion D- 34<br />

SMSF-E Slide Bush : Round Flange Pilot End Type, Anticorrosion D- 40<br />

SMSF-G Slide Bush : Round Flange Type, Anticorrosion D- 34<br />

SMSF-G-E Slide Bush : Round Flange Pilot End Type, Anticorrosion D- 40<br />

SMSF-GW Slide Bush : Round Flange Double-Wide Type, Anticorrosion D- 46<br />

SMSF-GW-E Slide Bush : Round Flange Double-Wide Pilot End Type, Anticorrosion D- 58<br />

SMSF-W Slide Bush : Round Flange Double-Wide Type, Anticorrosion D- 46<br />

SMSF-W-E Slide Bush : Round Flange Double-Wide Pilot End Type, Anticorrosion D- 58<br />

SMSFC Slide Bush : Center Mount Round Flange Type, Anticorrosion D- 52<br />

SMSFC-G Slide Bush : Center Mount Round Flange Type, Anticorrosion D- 52<br />

SMSJ Slide Unit : Clearance Adjustable Block Type, Anticorrosion E- 18<br />

SMSJ-G Slide Unit : Clearance Adjustable Block Type, Anticorrosion E- 18<br />

SMSK Slide Bush : Square Flange Type, Anticorrosion D- 36<br />

SMSK-E Slide Bush : Square Flange Pilot End Type, Anticorrosion D- 42<br />

SMSK-G Slide Bush : Square Flange Type, Anticorrosion D- 36<br />

SMSK-G-E Slide Bush : Square Flange Pilot End Type, Anticorrosion D- 42<br />

SMSK-GW Slide Bush : Square Flange Double-Wide Type, Anticorrosion D- 48<br />

SMSK-GW-E Slide Bush : Square Flange Double-Wide Pilot End Type, Anticorrosion D- 60<br />

SMSK-W Slide Bush : Square Flange Double-Wide Type, Anticorrosion D- 48<br />

SMSK-W-E Slide Bush : Square Flange Double-Wide Pilot End Type, Anticorrosion D- 60<br />

SMSKC Slide Bush : Center Mount Square Flange Type, Anticorrosion D- 54<br />

SMSKC-G Slide Bush : Center Mount Square Flange Type, Anticorrosion D- 54<br />

SMST Slide Bush : Two Side Cut Flange Type, Anticorrosion D- 38<br />

SMST-E Slide Bush : Two Side Cut Pilot End Flange Type, Anticorrosion D- 44<br />

SMST-G Slide Bush : Two Side Cut Flange Type, Anticorrosion D- 38<br />

SMST-G-E Slide Bush : Two Side Cut Pilot End Flange Type, Anticorrosion D- 44<br />

SMST-GW Slide Bush : Two Side Cut Double-Wide Flange Type, Anticorrosion D- 50<br />

SMST-GW-E Slide Bush : Two Side Cut Double-Wide Flange Pilot End Type, Anticorrosion D- 62<br />

SMST-W Slide Bush : Two Side Cut Double-Wide Flange Type, Anticorrosion D- 50<br />

SMST-W-E Slide Bush : Two Side Cut Double-Wide Flange Pilot End Type, Anticorrosion D- 62<br />

SMSTC Slide Bush : Two Side Cut Center Flange Type, Anticorrosion D- 56<br />

SMSTC-G Slide Bush : Two Side Cut Center Flange Type, Anticorrosion D- 56<br />

SMT Slide Bush : Two Side Cut Flange Type D- 38<br />

SMT-E Slide Bush : Two Side Cut Pilot End Flange Type D- 44<br />

SMT-G Slide Bush : Two Side Cut Flange Type D- 38<br />

SMT-G-E Slide Bush : Two Side Cut Pilot End Flange Type D- 44<br />

SMT-GW Slide Bush : Two Side Cut Double-Wide Flange Type D- 50<br />

SMT-GW-E Slide Bush : Two Side Cut Double-Wide Flange Pilot End Type D- 62<br />

SMT-W Slide Bush : Two Side Cut Double-Wide Flange Type D- 50<br />

INDEX-5

SMT-W-E Slide Bush : Two Side Cut Double-Wide Flange Pilot End Type D- 62<br />

SMTC Slide Bush : Two Side Cut Center Flange Type D- 56<br />

SMTC-G Slide Bush : Two Side Cut Center Flange Type D- 56<br />

SN Slide Shaft : NB Shaft G- 6<br />

SNB Slide Shaft : Pre-Drilled Shaft G- 9<br />

SNS Slide Shaft : NB Shaft, Anticorrosion G- 7<br />

SNSB Slide Shaft : Pre-Drilled Shaft, Anticorrosion G- 9<br />

SNT Slide Shaft : NB Pipe Shaft G- 8<br />

SNW Slide Shaft : Inch Size Shaft G- 10<br />

SNWS Slide Shaft : Inch Size Shaft, Anticorrosion G- 11<br />

SNW-PD Slide Shaft : Inch Size Pre-Drilled Shaft G- 12<br />

SNWS-PD Slide Shaft : Inch Size Pre-Drilled Shaft, Anticorrosion G- 13<br />

SPA Ball Spline : Aluminum Block Type B- 24<br />

SPA-S Ball Spline (Standard) : Standard Spline Assembly w/SPA nut B- 30<br />

SPA-W Ball Spline : Double-Wide Aluminum Block Type B- 26<br />

SPA-WS Ball Spline (Standard) : Standard Spline Assembly w/SPA-w nut B- 30<br />

SPLFS Stroke Ball Spline B- 44<br />

SPR Rotary Ball Spline B- 38<br />

SR Stroke Bush : Standard F- 4<br />

SR-B Stroke Bush : Double Retainer Type F- 6<br />

SR-BUU Stroke Bush : Double Retainer Type w/Seals F- 7<br />

SR-UU Stroke Bush : Standard w/Seals F- 5<br />

SRE Slide Rotary Bush F- 12<br />

SREK Slide Rotary Bush : Square Flange Type F- 14<br />

SS Slide Screw J- 7<br />

SSP Ball Spline : Cylindrical Type B- 16<br />

SSP-C Ball Spline : Commercial Spline Assembly w/SSP nut B- 31<br />

SSP-S Ball Spline : Standard Spline Assembly w/SSP nut B- 30<br />

SSPB Ball Spline : Block Type B- 28<br />

SSPB-C Ball Spline : Commercial Spline Assembly w/SSPB nut B- 31<br />

SSPB-S Ball Spline : Standard Spline Assembly w/SSPB nut B- 30<br />

SSPF Ball Spline : Round Flange Type B- 20<br />

SSPFS Ball Spline : Round Flange Type,Anticorrosion B- 20<br />

SSPF-C Ball Spline : Commercial Spline Assembly w/SSPF nut B- 31<br />

SSPF-S Ball Spline : Standard Spline Assembly w/SSPF nut B- 30<br />

SSPM Ball Spline : Cylindrical Keyless Type B- 18<br />

SSPM-S Ball Spline : Standard Spline Assembly w/SSPM nut B- 30<br />

SSPS Ball Spline : Cylindrical Type,Anticorrosion B- 16<br />

SSPT Ball Spline : Two Side Cut Flange Type B- 22<br />

SSPT-S Ball Spline : Standard Spline Assembly w/SSPT nut B- 30<br />

SV Slide Way H- 18<br />

SVS Slide Way : Anticorrosion H- 18<br />

SVT Slide Table H- 34<br />

SVTS Slide Table : Anticorrosion H- 34<br />

SVW Slide Way : Center Rail Type H- 26<br />

SVWS Slide Way : Center Rail Type, Anticorrosion H- 26<br />

INDEX-6<br />

<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

SW Slide Bush (Inch Standard) : Standard Type D- 98<br />

SW-AJ Slide Bush (Inch Standard) : Clearance Adjustable Type D-100<br />

SW-G Slide Bush (Inch Standard) : Standard Type D- 98<br />

SW-G-AJ Slide Bush (Inch Standard) : Clearance Adjustable Type D-100<br />

SW-G-OP Slide Bush (Inch Standard) : Open Type D-102<br />

SW-GR Slide Bush (Inch Standard) : Self-Aligning Type D- 92<br />

SW-GR-AJ Slide Bush (Inch Standard) : Self-Aligning, Clearance Adjustable Type D- 94<br />

SW-GR-OP Slide Bush (Inch Standard) : Self-Aligning, Open Type D- 96<br />

SW-GW Slide Bush (Inch Standard) : Double-Wide Type D-104<br />

SW-OP Slide Bush (Inch Standard) : Open Type D-102<br />

SW-W Slide Bush (Inch Standard) : Double-Wide Type D-104<br />

SWA Slide Unit (Inch Standard) : Block Type E- 38<br />

SWA-G Slide Unit (Inch Standard) : Block Type E- 38<br />

SWD Slide Unit (Inch Standard) : Clearance Adjustable Open Block Type E- 42<br />

SWD-G Slide Unit (Inch Standard) : Clearance Adjustable Open Block Type E- 42<br />

SWJ Slide Unit (Inch Standard) : Clearance Adjustable Block Type E- 40<br />

SWJ-G Slide Unit (Inch Standard) : Clearance Adjustable Block Type E- 40<br />

SWF Slide Bush (Inch Standard) : Round Flange Type D-106<br />

SWF-G Slide Bush (Inch Standard) : Round Flange Type D-106<br />

SWF-GW Slide Bush (Inch Standard) : Round Flange Double-Wide Type D-112<br />

SWF-W Slide Bush (Inch Standard) : Round Flange Double-Wide Type D-112<br />

SWFC Slide Bush (Inch Standard) : Center Mount Round Flange Type D-116<br />

SWFC-G Slide Bush (Inch Standard) : Center Mount Round Flange Type D-116<br />

SWK Slide Bush (Inch Standard) : Square Flange Type D-108<br />

SWK-G Slide Bush (Inch Standard) : Square Flange Type D-108<br />

SWK-GW Slide Bush (Inch Standard) : Square Flange Double-Wide Type D-114<br />

SWK-W Slide Bush (Inch Standard) : Square Flange Double-Wide Type D-114<br />

SWKC Slide Bush (Inch Standard) : Center Mount Square Flange Type D-118<br />

SWKC-G Slide Bush (Inch Standard) : Center Mount Square Flange Type D-118<br />

SWS Slide Bush (Inch Standard) : Standard Type, Anticorrosion D- 98<br />

SWS-AJ Slide Bush (Inch Standard) : Clearance Adjustable Type, Anticorrosion D-100<br />

SWS-G Slide Bush (Inch Standard) : Standard Type, Anticorrosion D- 98<br />

SWS-G-AJ Slide Bush (Inch Standard) : Clearance Adjustable Type, Anticorrosion D-100<br />

SWS-G-OP Slide Bush (Inch Standard) : Open Type, Anticorrosion D-102<br />

SWS-GW Slide Bush (Inch Standard) : Double-Wide Type, Anticorrosion D-104<br />

SWS-OP Slide Bush (Inch Standard) : Open Type, Anticorrosion D-102<br />

SWS-W Slide Bush (Inch Standard) : Double-Wide Type, Anticorrosion D-104<br />

SWSA Slide Bush (Inch Standard) : Block Type, Anticorrosion E- 38<br />

SWSA-G Slide Bush (Inch Standard) : Block Type, Anticorrosion E- 38<br />

SWSD Slide Bush (Inch Standard) : Clearance Adjustable Open Block Type, Anticorrosion E- 42<br />

SWSD-G Slide Bush (Inch Standard) : Clearance Adjustable Open Block Type, Anticorrosion E- 42<br />

SWSF Slide Bush (Inch Standard) : Round Flange Type, Anticorrosion D-106<br />

SWSF-G Slide Bush (Inch Standard) : Round Flange Type, Anticorrosion D-106<br />

SWSF-GW Slide Bush (Inch Standard) : Round Flange Double-Wide Type, Anticorrosion D-112<br />

SWSF-W Slide Bush (Inch Standard) : Round Flange Double-Wide Type, Anticorrosion D-112<br />

SWSFC Slide Bush (Inch Standard) : Center Mount Round Flange Type, Anticorrosion D-116<br />

SWSFC-G Slide Bush (Inch Standard) : Center Mount Round Flange Type, Anticorrosion D-116<br />

SWSJ Slide Bush (Inch Standard) : Clearance Adjustable Block Type, Anticorrosion E- 40<br />

SWSJ-G Slide Bush (Inch Standard) : Clearance Adjustable Block Type, Anticorrosion E- 40<br />

SWSK Slide Bush (Inch Standard) : Square Flange Type, Anticorrosion D-108<br />

SWSK-G Slide Bush (Inch Standard) : Square Flange Type, Anticorrosion D-108<br />

SWSK-GW Slide Bush (Inch Standard) : Square Flange Double-Wide Type, Anticorrosion D-114<br />

SWSK-W Slide Bush (Inch Standard) : Square Flange Double-Wide Type, Anticorrosion D-114<br />

SWSKC Slide Bush (Inch Standard) : Center Mount Square Flange Type, Anticorrosion D-118<br />

SWSKC-G Slide Bush (Inch Standard) : Center Mount Square Flange Type, Anticorrosion D-118<br />

INDEX-7

SY <br />

SY<br />

<br />

<br />

<br />

SWST Slide Bush (Inch Standard) : Two Side Cut Flange Type, Anticorrosion D-110<br />

SWST-G Slide Bush (Inch Standard) : Two Side Cut Flange Type, Anticorrosion D-110<br />

SWT Slide Bush (Inch Standard) : Two Side Cut Flange Type D-110<br />

SWT-G Slide Bush (Inch Standard) : Two Side Cut Flange Type D-110<br />

SYBS Slide Table : Ultra Compact Type H- 52<br />

SYT Slide Table : Compact Type H- 40<br />

SYT-D Slide Table : Compact Type w/Counter Bored Rail H- 44<br />

SYTS Slide Table : Compact Type, Anticorrosion H- 40<br />

SYTS-D Slide Table : Compact Type w/Counter Bored Rail, Anticorrosion H- 44<br />

TRF Slide Bush : Triple-Wide Round Flange Type D- 64<br />

TRF-E Slide Bush : Triple-Wide Round Flange Pilot End Type D- 72<br />

TRF-G Slide Bush : Triple-Wide Round Flange Type D- 64<br />

TRF-G-E Slide Bush : Triple-Wide Round Flange Pilot End Type D- 72<br />

TRFC Slide Bush : Triple-Wide Intermediate Position Round Flange Type D- 68<br />

TRFC-G Slide Bush : Triple-Wide Intermediate Position Round Flange Type D- 68<br />

TRK Slide Bush : Triple-Wide Square Flange Type D- 66<br />

TRK-E Slide Bush : Triple-Wide Square Flange Pilot End Type D- 74<br />

TRK-G Slide Bush : Triple-Wide Square Flange Type D- 66<br />

TRK-G-E Slide Bush : Triple-Wide Square Flange Pilot End Type D- 74<br />

TRKC Slide Bush : Triple-Wide Intermediate Position Square Flange Type D- 70<br />

TRKC-G Slide Bush : Triple-Wide Intermediate Position Square Flange Type D- 70<br />

TK Topball Slide Bush (Euro Standard) : Standard Type C- 8<br />

TK-OP Topball Slide Bush (Euro Standard) : Open Type C- 8<br />

TKA Slide Unit using Topball (Euro Standard) : Block Type C- 12<br />

TKA-W Slide Unit using Topball (Euro Standard) : Double-Wide Block Type C- 13<br />

TKD Slide Unit using Topball (Euro Standard) : Clearance Adjustable Open Block Type C- 16<br />

TKD-W Slide Unit using Topball (Euro Standard) : Clearance Adjustable Double-Wide Open Block Type C- 17<br />

TKE Slide Unit using Topball (Euro Standard) : Non-Clearance Adjustable Open Block Type C- 14<br />

TKE-W Slide Unit using Topball (Euro Standard) : Non-Clearance Adjustable Double-Wide Open Block Type C- 15<br />

TW Topball Slide Bush (Inch Standard) : Standard Type C- 10<br />

TW-OP Topball Slide Bush (Inch Standard) : Open Type C- 10<br />

TWA Slide Unit using Topball (Inch Standard) : Block Type C- 18<br />

TWA-W Slide Unit using Topball (Inch Standard) : Double-Wide Block Type C- 19<br />

TWD Slide Unit using Topball (Inch Standard) : Clearance Adjustable Open Block Type C- 22<br />

TWD-W Slide Unit using Topball (Inch Standard) : Clearance Adjustable Double-Wide Open Block Type C- 23<br />

TWJ Slide Unit using Topball (Inch Standard) : Clearance Adjustable Block Type C- 20<br />

TWJ-W Slide Unit using Topball (Inch Standard) : Clearance Adjustable Double-Wide Block Type C- 21<br />

WA Slide Unit (Inch Standard) : Shaft Support Rail E- 46<br />

WH-A Slide Unit (Inch Standard) : Alminum Shaft End Supporter E- 45<br />

INDEX-8<br />

<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

A-1<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

NB slide guides are high-precision and high-rigidity linear bearings designed to utilize the<br />

motion of rolling elements. They have numerous advantageous characteristics including<br />

low friction, no stick-slip, and smooth linear motion even under high load conditions. Since<br />

they can maintain their high-efficiency and high-functionality characteristics for an<br />

extended period of time, they meet a wide range of needs, from general industrial to<br />

precision machinery.<br />

A-2

Table A-1 Types<br />

miniature type<br />

high-rigidity type<br />

rolling<br />

element<br />

ball element<br />

roller<br />

ball element<br />

TYPE<br />

cross-section geometry and contact structure<br />

retained ball, 2-row, 4-point contact (SEBS-B type)<br />

2-row, 4-point contact (SEB-A type)<br />

crossroller (SER type)<br />

4-row, 2-point contact (GL type)<br />

4-row, 2-point contact (SGL type)<br />

4-row, 2-point contact (SGW type)<br />

A-3<br />

rerained ball type<br />

advantages<br />

available in all stainless steel<br />

2-row, compact<br />

small, light, cost effective<br />

2-row, compact<br />

small, light, cost effective<br />

available in various types<br />

available in stainless steel<br />

smallest roller guide<br />

crossroller, high precision<br />

available in all stainless steel<br />

Ball cushion contribute to low noise<br />

Employing the fiber sheet greatly<br />

Increased the lubrication interval.<br />

High load capacity / Long life<br />

high self-centering characteristics<br />

<br />

high loading capacity due to large number of<br />

ball elements<br />

high dust preventive control with side seal<br />

and under seal<br />

available in anticorrosion treatment<br />

high-moment resistant<br />

low-height design<br />

smooth motion due to large number of ball<br />

elements<br />

high dust preventive control with side seal<br />

and under seal<br />

available in anticorrosion treatment<br />

pages<br />

P.A-20<br />

P.A-20<br />

P.A-34<br />

P.A-42<br />

P.A-60<br />

P.A-76<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

ACCURACY MEASUREMENT METHOD<br />

The accuracy of slide guides is measured by fixing the rail to the datum base. The accuracy is expressed in<br />

terms of the average value at the center portion.<br />

Dimensional Tolerance and Paired Guide<br />

Difference:<br />

The accuracy of the slide guide is obtained by<br />

measuring the height, H, and width, W, as shown in<br />

Figure A-1. The dimensional tolerance is measured<br />

for each of the blocks attached to the rail and is<br />

expressed in terms of the deviation from the<br />

reference value. The paired-guide difference is<br />

obtained by measuring the blocks attached to the rail<br />

and is expressed in terms of the difference between<br />

the maximum and minimum values.<br />

Motion Accuracy:<br />

The rail is first fixed to the reference base. The<br />

motion accuracy is obtained by measuring the<br />

difference in the indicator readings when the block is<br />

moved along the entire span of the rail.<br />

Notation for Number of Rails and Paired<br />

Guide Difference:<br />

When more than two rails are used in parallel, the<br />

guide difference must be measured on more than<br />

one block. For measuring the height, H, the number<br />

of rails can be specified by simply indicating the<br />

necessary number of rails in the part number call-out.<br />

For measuring the width, W, contact NB.<br />

Note When four rails are used as illustrated in Figure<br />

A-3, W4 should be specified in the call-out. Please<br />

indicate the number of rails when ordering.<br />

A-4<br />

Figure A-1 Accuracy Measurement<br />

reference surface NB mark<br />

Figure A-2 Measurement Method for Motion Accuracy<br />

example part number<br />

SGL25TF2-350/ W 2<br />

Figure A-3 4-Parallel Rows<br />

reference<br />

base<br />

symbol for number of rails<br />

W 2 : 2 parallel rows<br />

W 3 : 3 parallel rows

RIGIDITY AND PRE-LOAD<br />

The rolling elements of the slide guide deform<br />

elastically due to the applied load. The amount of<br />

deformation depends on the type of rolling element. It<br />

is proportional to the 2/3rd power for ball elements.<br />

For rollers, it is proportional to the 0.9th power. In<br />

either case, the amount of deformation decreases as<br />

the applied load increases. Greater rigidity is<br />

achieved by applying a pre-load.<br />

A pre-load causes internal stress within the slide<br />

guide, resulting in some reduction in lifetime.<br />

However, when the part is used under shock or<br />

vibration loading conditions, a pre-load will absorb<br />

the load and will actually help lengthen the life of the<br />

part. Because the pre-load causes elastic<br />

deformation of the rolling elements, it becomes less<br />

tolerable to the installation dimensional difference.<br />

Extreme care should be exercised in machining the<br />

installation surface.<br />

Three primary ranges of pre-loads are available from<br />

NB: normal, light, and medium. This allows the user<br />

to select the appropriate level for the application.<br />

Table A-2 Type of Pre-Load<br />

type of<br />

pre-load<br />

standard<br />

light<br />

medium<br />

symbol<br />

none<br />

T1<br />

T2<br />

vibration<br />

absorption<br />

ability<br />

increases<br />

effect of pre-load<br />

selfaligning<br />

ability<br />

lifetime rigidity<br />

reduces<br />

reduces<br />

A-5<br />

<br />

Figure A-4 Elastic Deformation of Rolling Elements<br />

amount of elastic deformation<br />

increases<br />

frictional<br />

resistance<br />

increases<br />

P1:pre-load<br />

P2:zero pre-load<br />

applied load<br />

zero clearance<br />

operating environment<br />

with pre-load roller and<br />

zero clearance<br />

flat surface<br />

with pre-load<br />

ball and<br />

curvature<br />

surface<br />

minute vibration is applied, accurate<br />

motion is required, moment is applied in a<br />

given direction<br />

light vibration is applied, slight torsion is<br />

applied, moment is applied<br />

shock and vibration are applied, over-hang<br />

load is applied, torsion is applied<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

RATED LOAD AND RATED LIFE<br />

Loading Direction and Rated Load:<br />

A slide guide experiences load and moment, as shown in Figure A-5. For each load and moment, the Basic load<br />

rating and allowable static moment are defined.<br />

Figure A-5 Direction of Loading<br />

rated load<br />

C and Co<br />

Rated Life Calculation:<br />

Two types of rolling elements are used in NB slide<br />

guides: ball or roller elements. There is a different<br />

equation for calculating the rated life of each type.<br />

For ball element slide guides (types SEB, SGL and<br />

SGW), the equation is:<br />

3<br />

L= 50(6) fc C<br />

<br />

fw P<br />

For roller element slide guides (type SER), the<br />

equations is:<br />

10/3<br />

L= 50(7)<br />

fcfT C<br />

<br />

fw P<br />

L : travel life (km) fc : contact coefficent<br />

fT : temperature coefficent fw : load coefficent<br />

C : basic dynamic load rating (N) P : load (N)<br />

Refer to page Eng. 5 for a description of each coefficient<br />

The contact coefficient is used when two or more slides are used in close<br />

proximity to each other.<br />

A-6<br />

moment<br />

If the stroke distance and frequency are constant, life<br />

can be expressed in terms of time, the equation is:<br />

L10 3<br />

Lh= (8)<br />

2sn160<br />

Lh : travel life in time (hr) s : stroke distance (mm)<br />

L : travel life (km) n1 : stroke frequency per min (cpm)

MOUNTING<br />

A-7<br />

<br />

Slide guides have a high rated load capacity in spite of their compact size. They can be used in various types of<br />

machinery and other equipment using various methods. Figure A-6 shows some representative slide guide<br />

arrangements.<br />

Figure A-6 Slide Guide Arrangements<br />

1 rail horizontal (light load)<br />

2 rails horizontal (light load)<br />

reference surface<br />

2 rails sideways<br />

reference<br />

surface<br />

reference<br />

surface<br />

reference<br />

surface<br />

reference surface<br />

reference surface<br />

1 rail sideway<br />

reference<br />

surface<br />

reference surface<br />

2 rails horizontal (medium high load)<br />

reference surface<br />

2 rails opposing<br />

reference surface<br />

reference<br />

surface<br />

reference<br />

surface<br />

reference<br />

surface<br />

2 rails horizontal (moving rail)<br />

reference surface<br />

reference<br />

surface<br />

reference surface<br />

reference surface reference surface<br />

Refer to the next page for the area indicated by "".<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

Mounting Surface Shape and Accuracy:<br />

NB slide guides are designed and fabricated to be<br />

accurately mounted by attaching them to a machined<br />

mounting base. One approach is to provide a<br />

shoulder on the mounting surface and align the<br />

reference surface of the rail or block against this<br />

surface (Figure A-7). To avoid corner interference, an<br />

escape groove should be provided at the shoulder<br />

corner or the radius of the shoulder corner should be<br />

smaller than the radius of the slide guide corner. The<br />

accuracy of the rail surface affects the accuracy of<br />

the machinery or other equipment along with the<br />

slide guide motion accuracy. The accuracy of the<br />

mounting surface should be equivalent to that of the<br />

desired slide guide motion accuracy. The specified<br />

pre-load may not be achieved due to deformation of<br />

the block, for example, the mounted block surface is<br />

not flat. Refer to Figure A-8. Careful attention should<br />

therefore be given to achieve the specified flatness.<br />

Reference Surface Indication:<br />

Reference surfaces are provided to enable accurate<br />

and simplified mounting. They are placed in the same<br />

direction on the block and the rail, as shown in Figure<br />

A-9. They are located on the side opposite to the NB<br />

mark.<br />

Depending on the mounting arrangement, the<br />

standard reference surface may not ensure mounting<br />

accuracy (for example, 1 rail sideway or 2 rails<br />

opposing, page A7, Figure A-6). In such cases, NB<br />

can provide a reference surface on the opposite side.<br />

This should be specified when ordering.<br />

A-8<br />

Figure A-7 Shape of Mounting Surface<br />

Figure A-8 Effect of Flatness<br />

Figure A-9 Reference Surfaces<br />

reference<br />

surface<br />

reference<br />

surface<br />

gap<br />

NB mark

A-9<br />

<br />

Mounting:<br />

In general, a slide guide is used with 2 rails in parallel. In that case, one rail is on the so-called reference side and<br />

the other is the so-called adjustable side.<br />

Applications where shock/vibration loading and<br />

high load are involved and high accuracy is required.<br />

The effect of shock and vibration on accuracy is<br />

eliminated by mounting on the slide guide a side<br />

piece, which is typically a side plate (Figure A-10),<br />

tightening set screws (Figure A-11), or a tapered<br />

gib (Figure A-12).<br />

Figure A-10 Mounting of Side Plate<br />

reference side adjustable side<br />

Provide an escape groove in the side plate, and push slightly protruding<br />

portion from the bed table.<br />

Applications where light load and low speed are<br />

involved.<br />

Figures A-1315 show the mounting methods<br />

when high accuracy is not required or the load<br />

capacity of the slide guide is sufficient due to a light<br />

load or low speed. In these cases, a side piece or<br />

reference surface may not be required.<br />

Figure A-13 Without Side Piece<br />

reference side adjustable side<br />

Figure A-11 Mounting of Tightening Set Screw<br />

reference side adjustable side<br />

Because space is limited in the guide rail portion, small screws must be<br />

used. Use as many screws as necessary for the length of the rail.<br />

Figure A-12 Mounting of Tapered Gib<br />

reference side adjustable side<br />

By rotating mounting screws of the tapered gib, the gib applies a side<br />

force to the slide guide. The groove shape and surrounding dimensions<br />

must be carefully designed to achieve the desired force.<br />

Figure A-14 No Datum Surface on Adjustable Side<br />

reference side adjustable side<br />

Figure A-15 Without Datum Surface<br />

reference side adjustable side<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

Mounting Method:<br />

When reference surfaces are provided for both the<br />

table and the base, use the following procedure to<br />

mount the slide guide.<br />

1. Remove burrs, scratches, dust, etc. from the base<br />

and table. Apply a low viscosity oil to the base and<br />

the table. Place the slide guide on the base carefully.<br />

Temporarily fix the rail mounting bolts.<br />

2. Tighten the screw for the side piece so that the<br />

installation reference surface and the rail reference<br />

surface are in contact. If a side piece is not provided,<br />

use a C clamp to position the mounting reference<br />

surface and the rail reference surface so that they<br />

contact each other.<br />

3. Tighten the mounting bolts to the specified torque,<br />

and <strong>complete</strong> the mounting of the rail. The rail is<br />

designed so that its accuracy is optimum when the<br />

bolts are tightened to the specified value. Refer to the<br />

recommended torgue table for each product type for<br />

the specified torque.<br />

4. Repeat steps 2 and 3 for the rail on the adjustable<br />

side.<br />

5. Move the blocks at the mounting location of the<br />

table, and place the table softly. Then slightly tighten<br />

the screws.<br />

6. Position the reference surface of the block against<br />

the table. Tighten the mounting screws in a diagonal<br />

sequence.<br />

7. Repeat steps 5 and 6 for the block on the<br />

adjustable side.<br />

A-10<br />

Figure A-16 Mounting Using Reference Surfaces<br />

When a side piece is not provided.

When reference surface is not provided on<br />

adjustable side:<br />

When a reference surface is not provided on the<br />

adjustable side, mount the 2 rails in parallel by using<br />

a jig, as mounted in Figure A-17. After mounting the<br />

reference-side guide, install the adjustable-side guide.<br />

When reference surface is not provided on<br />

reference side:<br />

When a reference surface is not provided on the<br />

reference side, mount the 2 rails by using a reference<br />

surface in the vicinity of the slide guide, as illustrated<br />

in Figure A-18.<br />

Temporarily fix the slide guide to the base, and mount<br />

an indicator on the block. Two or more blocks should<br />

be used; they should be fixed using a measurement<br />

plate (Figure A-18).<br />

Place the indicator against the reference surface of<br />

the base. Tighten the bolts from one end of the rail to<br />

ensure straightness. If there is no reference surface<br />

handy, use a straight edge to achieve straightness<br />

(Figure A-19).<br />

Note:<br />

The SEB-A and SER slide guides do not have ball<br />

element retainers, so if they must be removed from<br />

the mounting rail, use a temporary rail to prevent the<br />

ball elements from falling out will be necessary.<br />

Although the SEBS-B SGL and SGW slide guides do<br />

have ball element retainers, the ball elements may<br />

still fall out depending upon how the guide block is<br />

removed from the rail and also the pre-load condition.<br />

The use of a temporary rail is strongly recommended<br />

to prevent damage to the guide block (Figure A-20).<br />

Contact NB for information on temporary rails.<br />

A-11<br />

Figure A-17 Using a Jig<br />

jig<br />

Figure A-18 Using Base Reference Surface<br />

base reference<br />

surface<br />

Figure A-19 Using a Straight Edge<br />

Figure A-20 Guide Block Removal<br />

<br />

straight edge<br />

measurement plate<br />

temporary rail<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

RAIL LENGTH<br />

Guide Rail Length:<br />

Single rails are fabricated as standards to the lengths<br />

shown in the dimensional tables for each type and<br />

series. Unless otherwise specified, the distance to<br />

the first hole from one end of the rail (referred to as<br />

dimension "N") is within the range specified in the<br />

dimensional tables. The guide rail is therefore<br />

fabricated according to the equation given below. For<br />

other than standard dimensional requirements,<br />

contact NB.<br />

L = M P + 2N<br />

L : length (mm) N : distance to the first hole center from the end of the rail<br />

(mm) P : hole pitch (mm) M : number of pitches.<br />

Note:<br />

Slide guide rails are machined with mounting holes<br />

as depicted in Figure A-21 during the initial<br />

fabrication process (before heat treatment).<br />

Specifying a different hole pitch or size will increase<br />

the cost and lead time, so please try to avoid<br />

changing these specifications.<br />

JOINT RAILS<br />

Rails can be joined together to obtain a length which<br />

exceeds the specified maximum standard length.<br />

There are two ways to do this.<br />

Place the joints at the same location for the right<br />

and left rails so as to make the design and<br />

maintenance simple (Figure A-23 ).<br />

Place the joints for the right and left rails at<br />

different locations so that the block does not move<br />

over the two joints at the same time so as to<br />

minimize the effect of the joint on accuracy (Figure<br />

A-23 ).<br />

A-12<br />

Figure A-21 Guide Rail Mounting Hole<br />

Figure A-22 Guide Rail Grinding Method<br />

grinding stone<br />

Please keep the following points in mind when using<br />

joint rails.<br />

To avoid dislocation at joints due to shock loading,<br />

provide a shoulder at the joint on the installation<br />

side.<br />

Use the joint marks provided.<br />

Tightly butt the rails to be joined so that there is no<br />

gap between them.<br />

Notes:<br />

The standard accuracy and pre-load grade are only<br />

available on joined rail systems. The GL type and the<br />

SER type guide series can not be made with joined<br />

rails. Contact NB for further information on joining .

Figure A-23 Examples of Joined Guide Rails<br />

Joints for right/left rails are placed at the same location<br />

Joints for right/left rails are placed at different locations<br />

A-13<br />

Joint match mark<br />

Joint match mark<br />

Joint match mark<br />

<br />

Joint match mark<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

DUST PREVENTION<br />

Seals:<br />

Side seal (Series: SEB, SER, GL, SGL or SGW)<br />

Slide guides with side-seals are used in typical<br />

environments to prevent dust from entering the guide<br />

block from above.<br />

Under seal (Series: GL, SGL or SGW)<br />

Slide guides with side and under seals are used in<br />

more harsh environments or to prevent dust entering<br />

from below.<br />

Double Side Seal Option (Series: GL or SGL)<br />

With this option, the prevention against dust is greatly<br />

improved. Ideal for use in applications where bellows<br />

or covers are not able to be fitted over the system.<br />

No Side Seal (Series: SEB or SER)<br />

When the presence of dust or debris is extremely low<br />

and only minor motion resistance is desired, a No<br />

Side Seal option may be required. Be aware that with<br />

this option, that dust prevention can not be expected.<br />

A-14<br />

Figure A-24 Side-Seals and Under-Seals<br />

under-seal<br />

Figure A-25 Double Side-Seal Figure A-26 Scraper<br />

spacer<br />

side seal<br />

side-seal<br />

Scraper Option (Series: GL or SGL)<br />

When the working application environment has<br />

unfavorable foreign matter or debris such as welding<br />

splatter or cutting debris, the Scraper option provides<br />

an effective protective measure for the Guide Block.<br />

spacer<br />

scraper<br />

side seal

Bellows Option (Series: GL or SGL)<br />

This option fully covers the Slide Rail preventing dust,<br />

debris, and other foreign particles from disrupting the<br />

smooth linear motion movement. (Refer to Page A-16<br />

for further details)<br />

Special Cap:<br />

For GL, SGL and SGW guides, special rail mounting<br />

caps are available to prevent dust from entering the<br />

installation mounting holes. These caps are installed<br />

after the rail is installed by using a jig and slowly<br />

inserting them into the holes until their top surface is<br />

flush with the rail surface.<br />

Table A-3 Special Caps<br />

part number<br />

F3<br />

F4<br />

F5<br />

F6<br />

F8<br />

F12<br />

dimensions<br />

D mm t mm<br />

6.1 1.3<br />

7.6 1.1<br />

9.7 2.5<br />

11.2 2.7<br />

14.3 3.65<br />

20.3 4.65<br />

GL-F, E, TF, TE<br />

15<br />

15D<br />

20<br />

25,30<br />

35<br />

<br />

CORROSION RESISTANCE<br />

A-15<br />

Figure A-27 Optional Bellows<br />

Bellows<br />

Figure A-28 Special Cap Installation<br />

cap<br />

applicable slide guide<br />

GL-HTF, HTE SGL-F, E, TF, TE SGL-HTF, HTE<br />

<br />

15<br />

<br />

15<br />

15D<br />

15<br />

20<br />

20<br />

20<br />

25<br />

25,30<br />

25<br />

30,35<br />

35<br />

30,35<br />

45<br />

<br />

45<br />

<br />

insertion jig<br />

SGW<br />

<br />

17,21,27<br />

<br />

35<br />

<br />

For corrosion resistance, the SEB and SER guides are available in stainless steel material option. Raydent<br />

surface treatment can be specified for the GL, SGL and SGW guide series. This treatment is suitable for<br />

applications where corrosion resistance is required or periodic lubrication is difficult.<br />

LUBRICATION<br />

Lithium soap grease is applied to NB slide guides before they are shipped so that they are ready for immediate<br />

use. The same type of grease should be added periodically depending on the operating conditions.<br />

For GL, SGL, and SGW types, a Fiber Sheet is available which significantly extends lubricant replenishment<br />

intervals. Refer to page A-19 for details.<br />

For use in clean rooms or vacuum environments, slide guides without grease are available. Slide guides<br />

lubricated with customer specified grease for special applications are also available. Please contact us if you<br />

need such products.<br />

NB also provides low dust generation linear system lubricant. Please refer to page Eng-20 for further details.<br />

cap<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

BELLOWS<br />

By protecting the entire length of Guide Rails, the dust prevention is greatly enhanced. Please refer to Figure A-<br />

29 for dimensional information.<br />

External dimensions and the stroke of Slide Guide are affected when using bellows.<br />

Figure A-29 Dimensions of Slide Guide with Bellows<br />

guide fitting plate intermediate plate rail fitting plate<br />

t1 t2 max/1group t1<br />

min/1group<br />

Part Number<br />

GL 15F/TF/E/TE SGL 15F/TF/E/TE<br />

GL 15HTE SGL 15HTE<br />

GL 15HTF SGL 15HTF<br />

GL 20F/TF/E/TE SGL 20F/TF/E/TE<br />

GL 20HTF/HTE SGL 20HTF/HTE<br />

GL 25F/TF/E/TE SGL 25F/TF/E/TE<br />

GL 25HTF SGL 25HTF<br />

GL 25HTE SGL 25HTE<br />

GL 30F/TF/E/TE SGL 30F/TF/E/TE<br />

GL 30HTE SGL 30HTE<br />

GL 30HTF SGL 30HTF<br />

GL 35F/TF/E/TE SGL 35F/TF/E/TE<br />

GL 35HTE SGL 35HTE<br />

GL 35HTF SGL 35HTF<br />

GL 45HTF SGL 45HTF<br />

GL 45HTE SGL 45HTE<br />

Note: 1 group indicates the minimum unit of bellows.<br />

B<br />

33<br />

41<br />

47<br />

58<br />

68<br />

84<br />

H<br />

23<br />

27<br />

32<br />

40<br />

46<br />

59<br />

h<br />

1<br />

5<br />

1<br />

3<br />

1<br />

8<br />

4<br />

2<br />

5<br />

2<br />

9<br />

1<br />

11<br />

A-16<br />

b<br />

19<br />

21.5<br />

25.5<br />

31<br />

37<br />

50<br />

t1<br />

1.5<br />

2.0<br />

cross section of<br />

guide with bellow<br />

SGL 20 or smaller SGL 25 or larger<br />

Note: Do not remove the Guide Fitting Plate installation bolts or the Slide Guide is no longer functional.<br />

t2<br />

1.0<br />

max/1 group<br />

When bellows are fitted to the Guide Block, the grease fitting cannot be installed.<br />

Please contact NB for details on the installation of bellows, as well as for special application usage.<br />

B<br />

b<br />

h<br />

H<br />

32<br />

40<br />

44<br />

56<br />

68<br />

72<br />

B<br />

h<br />

b<br />

H<br />

min/1 group<br />

6.5

A-17<br />

<br />

Calulcation method of length of Bellows and Slide Guide Rails<br />

Example) In this case, one(1) piece of SGL15TE Guide Block is mounted on a Rail with Bellows; the required<br />

stroke is 420mm. Group numbers required for a stroke of 420mm is calculated as illustrated below.<br />

Stroke 440<br />

17.2 18 groups(round up)<br />

max- min 32-6.5<br />

When 18 groups of Bellows are fitted, the maximum length 1 is calculated:<br />

1guide fitting platemax/1 group number of groups + Intermediate plate (number of groups 1)<br />

1.5 + 32 18 + 1.0 (18 1) 594.5<br />

When 18 groups of Bellows are fitted, the minimum length 2 is calculated:<br />

2guide fitting plate min/1 group number of groups intermediate plate (number of groups-1)<br />

1.56.5181.0(18-1)135.5<br />

With these calculation results, stroke limit(S) and length of the guide rail needed(L)are obtained as follows:<br />

S12594.5135.5459<br />

L12length of SGL 15TE block594.5135.556.5786.5787(round up)<br />

Figure A-30 External diagram f Slide Guide with bellows attached<br />

When Slide Guide is moved to the left side<br />

2 1<br />

When Slide Guide is moved to the right side<br />

2<br />

SGL15TE: 56.5<br />

1<br />

S<br />

L<br />

L<br />

S<br />

SGL15TE: 56.5<br />

2<br />

2<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

FIBER SHEET<br />

For the NB slide guide GL, SGL, and SGW types, fiber sheets are available. The sheet significantly extends<br />

lubricant replenishment intervals and has an excellent durability even under harsh conditions with dust, which<br />

absorbs lubricant. Embedded in a block body, as shown in Fig.A-31, it does not change the length of the block. In<br />

addition, the fiber sheet does not require any change in mounting method, which allows replacement with<br />

existing products without a design change.<br />

Figure A-31 Detailed View of the Fiber Sheet<br />

A-18<br />

Fiber Sheet

Simplified lubrication management<br />

A-19<br />

<br />

NB's fiber sheet is material with a porous structure containing the lubricant oil. The oil is supplied to the ball<br />

elements at the proper time and in the proper amount by the principle of capillarity, greatly increasing the<br />

intervals between when oiling is required.<br />

Figure A-32 Degreased model durability test<br />

SGL35F model, tested without grease.<br />

Operation failed several hours after<br />

start of test.<br />

An acceleration test was performed with oil absorbing material sprayed on the units to validate the GL type's<br />

lubrication performance and durability even under poor operating conditions.<br />

Figure A-33 Lubrication acceleration test<br />

GL35F Fiber Sheet model, tested without grease.<br />

Operation for twice calculated service life ( 3)<br />

Quality and quantity of the oil remaining within the fiber<br />

sheet were both good.<br />

Test Conditions<br />

Load: 1/8 x C<br />

Speed: 60 m/min.<br />

Operating<br />

0 5,000 10,000 15,000<br />

3: Value for load coefficient of 1.5.<br />

Distance (km)<br />

Outstanding durability even under poor operating conditions<br />

SGL15TFBW + grease<br />

Oil film ran out after<br />

1,697 km, causing<br />

operation failure<br />

Operating<br />

0 1,000 2,000 3,000 4,000<br />

Distance (km)<br />

GL15TFBW Fiber Sheet + grease<br />

No problems noted even<br />

after 4,300 km of operation<br />

Test Conditions<br />

Load: 1/10 x MR<br />

Speed: 60 m/min.<br />

With oil absorbing<br />

material sprayed<br />

on unit<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

The SEB type slide guide is a linear motion bearing in which the ball elements roll along<br />

two tracking grooves. This is the smallest and lightest slide guide series offered by Nippon<br />

Bearing. The compact design allows for the size and weight of machinery and other<br />

equipment to be reduced.<br />

STRUCTURE AND ADVANTAGES<br />

The SEB type slide guide consists of a rail with<br />

precisely machined raceway grooves and a block<br />

assembly consisting of the main body, return caps<br />

and ball elements. Side-seals are available as an<br />

optional feature.<br />

Retained Ball:<br />

With the retained balls, the SEBS "B" type block is<br />

able to be removed from the guide rail, simplifying its<br />

installation and resulting in lower assembly costs.<br />

All Stainless Steel Type:<br />

By using Stainless Steel for the return caps, the<br />

SEBS "BM" type is constructed from only Stainless<br />

Steel making this the ideal choice for special<br />

environments such as high temperature, clean room,<br />

or vacuum applications.<br />

Figure A-34 Structure of SEB Type Slide Guide<br />

Miniature<br />

SEB Type<br />

A-20<br />

Moment Resistant:<br />

A wide block "WA" type, a long block "AY" type, and a<br />

wide/long block "WAY" type are moment resistant<br />

slide guides available. One of these should be<br />

suitable for any demanding operating condition.<br />

Tapped-Hole rail Types:<br />

Slide guides with clearance holes are standard and<br />

tapped holes are available upon request.<br />

Anti-Corrosion:<br />

The SEBS type slide guide uses Martensite stainless<br />

steel which is highly resistant to corrosion and may<br />

be used in hostile environments.<br />

SEB-B type (Retained ball type) SEB-A type (Non-Retained ball type)<br />

return cap<br />

side-seal<br />

block<br />

guide rail<br />

retainer<br />

guide rail<br />

ball<br />

retainer<br />

ball<br />

block<br />

return cap<br />

block<br />

side-seal guide rail<br />

ball elements

A-21<br />

<br />

The SEB(S) type slide guides are categorized according to their block shape and the rail installation method.<br />

They are also available in stainless steel and with or without optional side-seals.<br />

Table A-4 Type<br />

retained ball type<br />

All stainlless steel<br />

non-retained ball type<br />

Wide type<br />

Wide type<br />

standard block<br />

counterbore rail type<br />

SEBS-B type<br />

SEBS-BM type<br />

SEB-A type<br />

SEB-WA type<br />

TYPES<br />

P.A-26<br />

P.A-26<br />

P.A-30<br />

P.A-32<br />

long block<br />

counterbore rail type<br />

standard block<br />

tapped hole rail type<br />

SEBS-BY type SEBS-B-N type<br />

P.A-26 P.A-26<br />

SEB-AY type SEB-A-N type<br />

P.A-30 P.A-30<br />

long block<br />

tapped hole rail type<br />

SEBS-BY-N type<br />

SEBS-BYM type SEBS-BM-N type<br />

SEBS-BYM-N type<br />

P.A-26 P.A-26<br />

P.A-26<br />

SEBS-WB type SEBS-WBY type SEBS-WB-N type<br />

SEBS-WBY-N type<br />

SEB-AY-N type<br />

SEB-WAY type SEB-WA-N type<br />

SEB-WAY-N type<br />

P.A-26<br />

P.A-28 P.A-28 P.A-28<br />

P.A-28<br />

P.A-30<br />

P.A-32 P.A-32<br />

P.A-32<br />

SLIDE GUIDE<br />

BALL SPLINE<br />

ROTARY BALL SPLINE<br />

STROKE BALL SPLINE<br />

TOPBALL PRODUCTS SLIDE BUSH SLIDE UNIT<br />

STROKE BUSH<br />

SLIDEROTARYBUSH<br />

SLIDE SHAFT<br />

SLIDE WAY/GONIO WAY<br />

SLIDE TABLE<br />

MINIATURE SLIDE<br />

ACTUATOR SLIDE SCREW

ACCURACY<br />

The SEB(S) slide guides are available in two grades<br />

of accuracy: high-grade and precision-grade (P).<br />

Table A-5 Accuracy unit/mm<br />

accuracy grade<br />

high precision<br />

accuracy symbol<br />

none P<br />

allowable dimensional difference in height H 0.020 0.010<br />

paired difference for height H 0.015 0.007<br />

allowable dimensional difference in width W 0.025 0.015<br />

paired difference for width W 0.020 0.010<br />

Running parallelism of surface C to surface A<br />

Running parallelism of surface D to surface B<br />

Refer to Figure A-36<br />

Figure A-36 Motion Accuracy<br />

running parallelism<br />

PRE-LOAD<br />

guide length<br />