- Page 1: TECHNICAL MANUAL OPERATOR’S MANUA

- Page 4 and 5: TM 1-1520-240-10 b Change 1 WARNING

- Page 7: URGENT TM 1-1520-240-10 CHANGE HEAD

- Page 11 and 12: *Zero in this column indicates an o

- Page 13 and 14: TM 1-1520-240-10 TECHNICAL MANUAL H

- Page 15: TM 1-1520-240-10 Chapter/Section Pa

- Page 18 and 19: TM 1-1520-240-10 1-1-13. Aircraft D

- Page 20 and 21: TM 1-1520-240-10 2-1-2 Figure 2-1-1

- Page 22 and 23: TM 1-1520-240-10 2-1-4 Figure 2-1-3

- Page 24 and 25: TM 1-1520-240-10 2-1-10. Brakes and

- Page 26 and 27: TM 1-1520-240-10 2-1-8 Figure 2-1-5

- Page 28 and 29: TM 1-1520-240-10 2-1-10 Figure 2-1-

- Page 30 and 31: TM 1-1520-240-10 2-1-12 Figure 2-1-

- Page 32 and 33: TM 1-1520-240-10 2-1-14 Figure 2-1-

- Page 34 and 35: TM 1-1520-240-10 2-1-16 Figure 2-1-

- Page 36 and 37: TM 1-1520-240-10 2-1-18 Figure 2-1-

- Page 38 and 39: TM 1-1520-240-10 2-2-2 Fwd Valve Fw

- Page 40 and 41: TM 1-1520-240-10 2-2-8. TROOP WARN

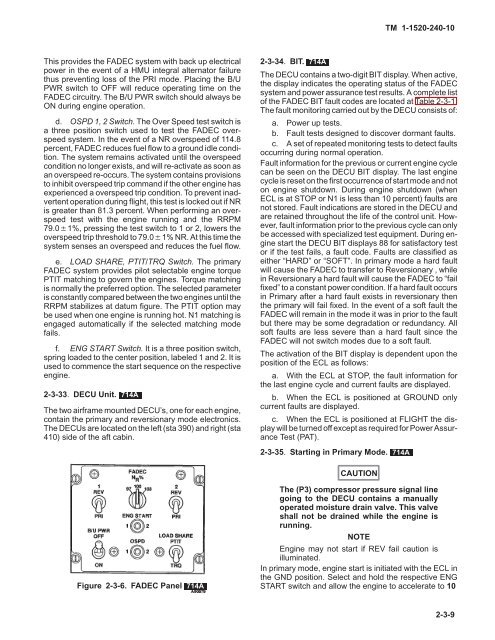

- Page 42 and 43: TM 1-1520-240-10 The power turbine

- Page 44 and 45: TM 1-1520-240-10 Figure 2-3-2. Emer

- Page 46 and 47: TM 1-1520-240-10 and NO. 2 OIL TEMP

- Page 50 and 51: TM 1-1520-240-10 2-3-10 Figure 2-3-

- Page 52 and 53: TM 1-1520-240-10 Table 2-3-1. T55-G

- Page 54 and 55: TM 1-1520-240-10 2-3-14 Table 2-3-1

- Page 56 and 57: TM 1-1520-240-10 Table 2-3-1. T55-G

- Page 58 and 59: TM 1-1520-240-10 2-3-18 Figure 2-3-

- Page 61 and 62: 2-4-1. Fuel Supply System. The fuel

- Page 63 and 64: 2-4-6. Manual Defueling Valve. A ma

- Page 65 and 66: 2-4-6). The switches are used to te

- Page 67 and 68: 2-5-1. Flight Control System. The h

- Page 69 and 70: Figure 2-5-2. Cyclic Stick Grip 2-5

- Page 71 and 72: (1) HDG Switch. The HDG (heading) s

- Page 73 and 74: 2-6-1. Hydraulic Power Supply Syste

- Page 75 and 76: us through the RAMP PWR switch and

- Page 77 and 78: TM 1-1520-240-10 No. 2 engine trans

- Page 79 and 80: TM 1-1520-240-10 2-7-12. Transmissi

- Page 82 and 83: 2-9-1. Anti Icing Systems. Anti ici

- Page 84 and 85: through the HYDRAULICS MAINT PNL LT

- Page 86 and 87: TM 1-1520-240-10 SECTION X. HEATING

- Page 88 and 89: TM 1-1520-240-10 SECTION XI. ELECTR

- Page 90: 2-11-7. BATT Switch. NOTE The follo

- Page 93 and 94: TM 1-1520-240-10 2-12-2 Figure 2-12

- Page 95 and 96: TM 1-1520-240-10 a. Electroluminesc

- Page 97 and 98: TM 1-1520-240-10 2-13-4 Figure 2-13

- Page 99 and 100:

TM 1-1520-240-10 bulkhead. The six

- Page 101 and 102:

TM 1-1520-240-10 2-13-8 Figure 2-13

- Page 104 and 105:

2-14-1. General. The following para

- Page 106 and 107:

When the helicopter descends below

- Page 108 and 109:

2-14-13. Controls and Function, Rad

- Page 110 and 111:

2-14-21. CHRONOMETER. Two digital c

- Page 112 and 113:

Table 2-14-1. Master Caution Panel

- Page 114 and 115:

2-14-30. CAUTION LT Panel. The CAUT

- Page 116 and 117:

SECTION XV. SERVICING, PARKING, AND

- Page 118 and 119:

k. Remove ground cables from the he

- Page 120 and 121:

Figure 2-15-2. Servicing Diagram (S

- Page 122 and 123:

Figure 2-15-2. Servicing Diagram (S

- Page 124 and 125:

TM 1-1520-240-10 Table 2-15-1. Serv

- Page 126 and 127:

Table 2-15-3. JP-4 Equivalent Fuel

- Page 128 and 129:

2-15-7. Gravity Refueling. Perform

- Page 130 and 131:

2-15-15. Transmission Oil System. S

- Page 132 and 133:

FLIGHT CONTROL, UTILITY, POWER STEE

- Page 134 and 135:

Figure 2-15-4. Protective Covers TM

- Page 136:

Figure 2-15-6. Installation of Heli

- Page 139 and 140:

TM 1-1520-240-10 3-1-2 Table 3-1-1.

- Page 141 and 142:

TM 1-1520-240-10 3-2-2 Figure 3-2-1

- Page 143 and 144:

TM 1-1520-240-10 3-2-6. Word-of-Day

- Page 145 and 146:

TM 1-1520-240-10 3-2-9. Conferencin

- Page 147 and 148:

TM 1-1520-240-10 SET. 3-2-8 (2) Cha

- Page 149 and 150:

TM 1-1520-240-10 3-2-10 NOTE The an

- Page 151 and 152:

TM 1-1520-240-10 c. Frequency Range

- Page 153 and 154:

TM 1-1520-240-10 3-2-19. Controls a

- Page 155 and 156:

TM 1-1520-240-10 3-2-21. HF Radio S

- Page 157 and 158:

TM 1-1520-240-10 3-2-24. Operating

- Page 159 and 160:

TM 1-1520-240-10 CONTROLS/ FUNCTION

- Page 161 and 162:

TM 1-1520-240-10 CONTROLS/ INDICATO

- Page 163 and 164:

TM 1-1520-240-10 CONTROLS/ FUNCTION

- Page 165 and 166:

TM 1-1520-240-10 (6) Push the INIT

- Page 167 and 168:

TM 1-1520-240-10 NOTE To exit and s

- Page 169 and 170:

TM 1-1520-240-10 CONTROLS/ FUNCTION

- Page 171 and 172:

TM 1-1520-240-10 3-3-8. Gyromagneti

- Page 173 and 174:

TM 1-1520-240-10 3-3-6 Figure 3-3-5

- Page 175 and 176:

TM 1-1520-240-10 CONTROLS/ INDICATO

- Page 177 and 178:

TM 1-1520-240-10 LEFT DISPLAY RIGHT

- Page 179 and 180:

TM 1-1520-240-10 e. FLY-TO DEST thu

- Page 181 and 182:

TM 1-1520-240-10 from the No. 2 (No

- Page 183 and 184:

TM 1-1520-240-10 3-3-35. Horizontal

- Page 185 and 186:

TM 1-1520-240-10 CONTROLS/ INDICATO

- Page 187 and 188:

TM 1-1520-240-10 tered in any of th

- Page 189 and 190:

TM 1-1520-240-10 (7) Observe the CD

- Page 191 and 192:

TM 1-1520-240-10 LEFT DISPLAY RIGHT

- Page 193 and 194:

TM 1-1520-240-10 3-3-26 NOTE To acc

- Page 195 and 196:

TM 1-1520-240-10 (3) Position updat

- Page 197 and 198:

TM 1-1520-240-10 (4) To select the

- Page 199 and 200:

TM 1-1520-240-10 NOTE In this mode,

- Page 201 and 202:

TM 1-1520-240-10 Table 3-3-4. Map D

- Page 204 and 205:

3-4-1. Transponder System (AN/APX-1

- Page 206 and 207:

3-4-3. Normal Operation — Transpo

- Page 208 and 209:

4-1-1. Radar Signal Detecting, AN/A

- Page 210 and 211:

4-1-2. CONTROLS AND FUNCTION, RADAR

- Page 212 and 213:

4-1-3). Check OFP and EID numbers a

- Page 214 and 215:

4-1-6. Controls and Indicators, Mis

- Page 216 and 217:

CONTROLS/ FUNCTION INDICATOR ARM In

- Page 218 and 219:

Figure 4-1-6. Flare Dispenser Syste

- Page 220 and 221:

4-1-18. Controls and Function, Coun

- Page 222 and 223:

4-1-24. Normal Operation. WARNING K

- Page 224 and 225:

4-1-26. CMDS Messages. Below is a l

- Page 226 and 227:

Figure 4-1-8. Heads Up Display AN/A

- Page 228 and 229:

No. Symbol Source Range/Description

- Page 230 and 231:

CAUTION Keep the protective caps on

- Page 232 and 233:

8. MODE 1-4/DCLT switch — DCLT (1

- Page 234 and 235:

4-2-1. Armament Subsystems The arma

- Page 236 and 237:

Figure 4-2-1. Armament Subsystem TM

- Page 238 and 239:

single cartridges or short bursts c

- Page 240 and 241:

Figure 4-2-5. Right Machine Gun Mou

- Page 242 and 243:

Figure 4-2-8. Ammunition Can — In

- Page 244:

Figure 4-2-10. M41 Mount — Instal

- Page 247 and 248:

TM 1-1520-240-10 (3) Cable cutter s

- Page 249 and 250:

TM 1-1520-240-10 4-3-4 Figure 4-3-2

- Page 251 and 252:

TM 1-1520-240-10 4-3-6 Figure 4-3-3

- Page 253 and 254:

TM 1-1520-240-10 (3) Hoist master s

- Page 255 and 256:

TM 1-1520-240-10 (2) Break the shea

- Page 257 and 258:

TM 1-1520-240-10 Figure 4-3-10. Hoi

- Page 259 and 260:

TM 1-1520-240-10 The hook assembly

- Page 261 and 262:

TM 1-1520-240-10 Figure 4-3-12. Cen

- Page 263 and 264:

TM 1-1520-240-10 4-3-18 CAUTION The

- Page 265 and 266:

TM 1-1520-240-10 HOOK OPEN caution

- Page 267 and 268:

TM 1-1520-240-10 4-3-22 Figure 4-3-

- Page 269 and 270:

TM 1-1520-240-10 4-3-24 Figure 4-3-

- Page 272 and 273:

TM 1-1520-240-10 SECTION IV. EXTEND

- Page 274 and 275:

Figure 4-4-1. ERFS II Fuel Tank TM

- Page 276 and 277:

Figure 4-4-2. ERFS II Fuel Control

- Page 278:

4-4-9. FARE Transfer. CAUTION Some

- Page 282 and 283:

5-2-1. Instrument Markings. 5-2-2.

- Page 284 and 285:

400 810 890 781 940 890 O C C C C C

- Page 286 and 287:

Figure 5-2-1 Instrument Markings (S

- Page 288:

5-3-1. Engine Rating and Power Leve

- Page 292 and 293:

5-5-1. Airspeed Operating Limits. A

- Page 294:

Figure 5-5-2. Airspeed Limitations

- Page 298 and 299:

5-7-1. Engine Inlet Screen Limitati

- Page 300 and 301:

Figure 5-7-1. Rotor Blade Start-Up

- Page 302:

TM 1-1520-240-10 5-7-5/(5-7-6 blank

- Page 305 and 306:

TM 1-1520-240-10 SEA STATE 5-8-2 Ta

- Page 308 and 309:

6-1-1. Purpose. This chapter contai

- Page 310:

6-2-1. DD Form 365-3 Chart C — Ba

- Page 313 and 314:

TM 1-1520-240-10 6-3-2 Figure 6-3-1

- Page 315 and 316:

TM 1-1520-240-10 6-4-11. Litter Sup

- Page 317 and 318:

TM 1-1520-240-10 6-4-4 Figure 6-4-2

- Page 319 and 320:

TM 1-1520-240-10 6-4-6 Figure 6-4-4

- Page 321 and 322:

TM 1-1520-240-10 6-4-8 Figure 6-4-5

- Page 323 and 324:

TM 1-1520-240-10 6-4-10 Figure 6-4-

- Page 326 and 327:

6-5-1. Mission Equipment. CH-47D mi

- Page 328:

Figure 6-5-1. Mission Equipment Wei

- Page 331 and 332:

TM 1-1520-240-10 6-6-8. Uniformly D

- Page 333 and 334:

TM 1-1520-240-10 6-6-10. Concentrat

- Page 335 and 336:

TM 1-1520-240-10 face of the floor.

- Page 337 and 338:

TM 1-1520-240-10 6-6-8 Figure 6-6-3

- Page 339 and 340:

TM 1-1520-240-10 6-6-10 Figure 6-6-

- Page 341 and 342:

TM 1-1520-240-10 6-6-12 Figure 6-6-

- Page 343 and 344:

TM 1-1520-240-10 6-6-21. Winch. Ref

- Page 345 and 346:

TM 1-1520-240-10 6-6-16 CAUTION Do

- Page 347 and 348:

TM 1-1520-240-10 6-6-35. Cargo Weig

- Page 349 and 350:

TM 1-1520-240-10 Figure 6-6-11. Car

- Page 351 and 352:

TM 1-1520-240-10 6-6-22 Figure 6-6-

- Page 353 and 354:

TM 1-1520-240-10 6-6-24 CAUTION Exc

- Page 355 and 356:

TM 1-1520-240-10 6-6-26 Table 6-6-2

- Page 357 and 358:

TM 1-1520-240-10 6-6-28 Table 6-6-3

- Page 359 and 360:

TM 1-1520-240-10 6-6-30 Figure 6-6-

- Page 361 and 362:

TM 1-1520-240-10 6-6-32 Figure 6-6-

- Page 363 and 364:

TM 1-1520-240-10 6-7-2 Figure 6-7-1

- Page 365 and 366:

TM 1-1520-240-10 b. Calculated Data

- Page 368 and 369:

7-2-1. Emergency Torque Available.

- Page 370 and 371:

SECTION III. MAXIMUM TORQUE AVAILAB

- Page 372:

Figure 7-3-2. Maximum Torque Availa

- Page 375 and 376:

TM 1-1520-240-10 7-4-2 Figure 7-4-1

- Page 377 and 378:

TM 1-1520-240-10 7-5-2 Figure 7-5-1

- Page 380 and 381:

7-6-1. Description. The takeoff cha

- Page 382 and 383:

7-7-1. Description. The cruise char

- Page 384 and 385:

Pressure OAT Altitude (ft) (C) Tabl

- Page 386 and 387:

Pressure OAT Altitude (ft) (C) Tabl

- Page 388 and 389:

Figure 7-7-1 Example Cruise Chart (

- Page 390 and 391:

Figure 7-7-3. 98 and 100% Rotor RPM

- Page 392 and 393:

Figure 7-7-5. 98 and 100% Rotor RPM

- Page 394 and 395:

Figure 7-7-7. 100% Rotor RPM, 10 an

- Page 396 and 397:

Figure 7-7-9. 100% Rotor RPM, 50C,

- Page 398 and 399:

Figure 7-7-11. 98 and 100% Rotor RP

- Page 400 and 401:

Figure 7-7-13. 98 and 100% Rotor RP

- Page 402 and 403:

Figure 7-7-15. 100% Rotor RPM, 10 a

- Page 404 and 405:

Figure 7-7-17. 100% Rotor RPM, 50C,

- Page 406 and 407:

Figure 7-7-19. 98 and 100% Rotor RP

- Page 408 and 409:

Figure 7-7-21. 98 and 100% Rotor RP

- Page 410 and 411:

Figure 7-7-23. 100% Rotor RPM, 10 a

- Page 412 and 413:

Figure 7-7-25. 100% Rotor RPM, 50C,

- Page 414 and 415:

Figure 7-7-27. 98 and 100% Rotor RP

- Page 416 and 417:

Figure 7-7-29. 98 and 100% Rotor RP

- Page 418 and 419:

Figure 7-7-31. 100% Rotor RPM, 10 a

- Page 420 and 421:

Figure 7-7-33. 100% Rotor RPM, 50C,

- Page 422 and 423:

Figure 7-7-35. 98 and 100% Rotor RP

- Page 424 and 425:

Figure 7-7-37. 98 and 100% Rotor RP

- Page 426 and 427:

Figure 7-7-39. 100% Rotor RPM, 10 a

- Page 428 and 429:

Figure 7-7-41. 100% Rotor RPM, 50C,

- Page 430 and 431:

Figure 7-7-43. 98 and 100% Rotor RP

- Page 432 and 433:

Figure 7-7-45. 98 and 100% Rotor RP

- Page 434 and 435:

Figure 7-7-47. 100% Rotor RPM, 10 a

- Page 436 and 437:

Figure 7-7-49. 100% Rotor RPM, 50C,

- Page 438 and 439:

Figure 7-7-51. 98 and 100% Rotor RP

- Page 440 and 441:

Figure 7-7-53. 98 and 100% Rotor RP

- Page 442 and 443:

Figure 7-7-55. 100% Rotor RPM, 10 a

- Page 444 and 445:

Figure 7-7-57. 100% Rotor RPM, 50C,

- Page 446 and 447:

Figure 7-7-59. 98 and 100% Rotor RP

- Page 448 and 449:

Figure 7-7-61. 98 and 100% Rotor RP

- Page 450 and 451:

Figure 7-7-63. 100% Rotor RPM, 10 a

- Page 452 and 453:

Figure 7-7-65. 100% Rotor RPM, 50C,

- Page 454 and 455:

Figure 7-7-67. 98 and 100% Rotor RP

- Page 456 and 457:

Figure 7-7-69. 98 and 100% Rotor RP

- Page 458 and 459:

Figure 7-7-71. 100% Rotor RPM, 10 a

- Page 460 and 461:

Figure 7-7-73. 98 and 100% Rotor RP

- Page 462 and 463:

Figure 7-7-75. 98 and 100% Rotor RP

- Page 464 and 465:

Figure 7-7-77. 98 and 100% Rotor RP

- Page 466 and 467:

Figure 7-7-79. 98 and 100% Rotor RP

- Page 468 and 469:

Figure 7-7-81. 98 and 100% Rotor RP

- Page 470 and 471:

Figure 7-7-83. 100% Rotor RPM, -10

- Page 472 and 473:

7-8-1. Description. The drag chart

- Page 474 and 475:

7-9-1. Description. a. Climb and de

- Page 476 and 477:

Figure 7-9-2. Climb Performance (Sh

- Page 478 and 479:

7-10-1. Description. The idle fuel

- Page 480:

Figure 7-10-2. Idle Fuel Flow Chart

- Page 483 and 484:

TM 1-1520-240-10 7-11-2 Figure 7-11

- Page 485 and 486:

TM 1-1520-240-10 c. Estimated Data.

- Page 488 and 489:

SECTION II. CONTINGENCY TORQUE AVAI

- Page 490 and 491:

SECTION III. MAXIMUM TORQUE AVAILAB

- Page 492:

Figure 7A-3-2. Intermediate Torque

- Page 495 and 496:

TM 1-1520-240-10 7A-4-2 Figure 7A-4

- Page 497 and 498:

TM 1-1520-240-10 7A-5-2 Figure 7A-5

- Page 500 and 501:

7A-6-1. Description. The takeoff ch

- Page 502 and 503:

7A-7-1. Description. The cruise cha

- Page 504 and 505:

Pressure OAT Altitude (ft) (C) Tabl

- Page 506 and 507:

Pressure OAT Altitude (ft) (C) Tabl

- Page 508 and 509:

Figure 7A-7-1. Example Cruise Chart

- Page 510 and 511:

Figure 7A-7-3. 98 and 100% Rotor RP

- Page 512 and 513:

Figure 7A-7-5. 98 and 100% Rotor RP

- Page 514 and 515:

Figure 7A-7-7. 100% Rotor RPM, 10 a

- Page 516 and 517:

Figure 7A-7-9. 100% Rotor RPM, 50C,

- Page 518 and 519:

Figure 7A-7-11. 98 and 100% Rotor R

- Page 520 and 521:

Figure 7A-7-13. 98 and 100% Rotor R

- Page 522 and 523:

Figure 7A-7-15. 100% Rotor RPM, 10

- Page 524 and 525:

Figure 7A-25. Figure 7A-7-17. 100%

- Page 526 and 527:

Figure 7A-7-19. 98 and 100% Rotor R

- Page 528 and 529:

Figure 7A-7-21. 98 and 100% Rotor R

- Page 530 and 531:

Figure 7A-7-23. 100% Rotor RPM, 10

- Page 532 and 533:

Figure 7A-7-25. 100% Rotor RPM, 50C

- Page 534 and 535:

Figure 7A-36. Figure 7A-7-27. 98 an

- Page 536 and 537:

Figure 7A-7-29. 98 and 100% Rotor R

- Page 538 and 539:

Figure 7A-7-31. 100% Rotor RPM, 10

- Page 540 and 541:

Figure 7A-7-33. 100% Rotor RPM, 50C

- Page 542 and 543:

Figure 7A-7-35. 98 and 100% Rotor R

- Page 544 and 545:

Figure 7A-46. Figure 7A-7-37. 98 an

- Page 546 and 547:

Figure 7A-7-39. 100% Rotor RPM, 10

- Page 548 and 549:

Figure 7A-7-41. 100% Rotor RPM, 50C

- Page 550 and 551:

Figure 7A-7-43. 98 and 100% Rotor R

- Page 552 and 553:

Figure 7A-7-45. 98 and 100% Rotor R

- Page 554 and 555:

Figure 7A-7-47. 100% Rotor RPM, 10

- Page 556 and 557:

Figure 7A-7-49. 100% Rotor RPM, 50C

- Page 558 and 559:

Figure 7A-7-51. 98 and 100% Rotor R

- Page 560 and 561:

Figure 7A-7-53. 98 and 100% Rotor R

- Page 562 and 563:

Figure 7A-7-55. 100% Rotor RPM, 10

- Page 564 and 565:

Figure 7A-7-57. 100% Rotor RPM, 50C

- Page 566 and 567:

Figure 7A-7-59. 98 and 100% Rotor R

- Page 568 and 569:

Figure 7A-7-61. 98 and 100% Rotor R

- Page 570 and 571:

Figure 7A-7-63. 100% Rotor RPM, 10

- Page 572 and 573:

Figure 7A-7-65. 100% Rotor RPM, 50C

- Page 574 and 575:

Figure 7A-7-67. 98 and 100% Rotor R

- Page 576 and 577:

Figure 7A-7-69. 98 and 100% Rotor R

- Page 578 and 579:

Figure 7A-7-71. 100% Rotor RPM, 10

- Page 580 and 581:

Figure 7A-7-73. 98 and 100% Rotor R

- Page 582 and 583:

Figure 7A-7-75. 98 and 100% Rotor R

- Page 584 and 585:

Figure 7A-7-77. 100% Rotor RPM, -10

- Page 586 and 587:

Figure 7A-7-79. 98 and 100% Rotor R

- Page 588 and 589:

Figure 7A-7-81. 98 and 100% Rotor R

- Page 590 and 591:

Figure 7A-7-83. 100% Rotor RPM, -10

- Page 592 and 593:

7A-8-1. Description. The drag chart

- Page 594 and 595:

7A-9-1. Description. a. Climb and d

- Page 596 and 597:

Figure 7A-9-2. Climb Performance (S

- Page 598 and 599:

7A-10-1. Description. The idle fuel

- Page 600:

Figure 7A-10-2. Single Engine Fuel

- Page 603 and 604:

TM 1-1520-240-10 7A-11-2 Figure 7A-

- Page 605 and 606:

TM 1-1520-240-10 d. Normal Procedur

- Page 607 and 608:

TM 1-1520-240-10 8-2-2 * 6. Forward

- Page 609 and 610:

TM 1-1520-240-10 8-2-4 18. 714A P3

- Page 611 and 612:

TM 1-1520-240-10 8-2-6 15. Upper bo

- Page 613 and 614:

TM 1-1520-240-10 8-2-8 * 20. Cyclic

- Page 615 and 616:

TM 1-1520-240-10 8-2-10 * 38. GEN 1

- Page 617 and 618:

TM 1-1520-240-10 8-2-12 Figure 8-2-

- Page 619 and 620:

TM 1-1520-240-10 Takeoff over water

- Page 621 and 622:

TM 1-1520-240-10 8-2-16 14. PWR XFE

- Page 624 and 625:

8-3-1. General. The flight characte

- Page 626 and 627:

SECTION IV. ADVERSE ENVIRONMENTAL C

- Page 628 and 629:

8-4-17. Before Leaving Helicopter.

- Page 630:

operating in these conditions, shou

- Page 633 and 634:

TM 1-1520-240-10 nals will be used

- Page 635 and 636:

TM 1-1520-240-10 9-1-4 EMERGENCY EX

- Page 637 and 638:

TM 1-1520-240-10 9-1-10. Dual Engin

- Page 639 and 640:

TM 1-1520-240-10 Figure 9-1-4. 712

- Page 641 and 642:

TM 1-1520-240-10 Figure 9-1-4. 712

- Page 643 and 644:

TM 1-1520-240-10 Figure 9-1-6. 714A

- Page 645 and 646:

TM 1-1520-240-10 Figure 9-1-6. 714A

- Page 647 and 648:

TM 1-1520-240-10 9-1-16 Figure 9-1-

- Page 649 and 650:

TM 1-1520-240-10 2. ENG COND lever

- Page 651 and 652:

TM 1-1520-240-10 9-1-28. Engine Shu

- Page 653 and 654:

TM 1-1520-240-10 9-1-40. 714A Torqu

- Page 655 and 656:

TM 1-1520-240-10 9-1-54. FUEL LOW a

- Page 657 and 658:

TM 1-1520-240-10 9-1-65. Emergency

- Page 659 and 660:

TM 1-1520-240-10 9-1-73. Flight Con

- Page 662 and 663:

9-2-1. ARMAMENT 9-2-2. Armament Sub

- Page 664 and 665:

Figure FO-1. General Arrangement (S

- Page 666 and 667:

DC ALE 47 DCDU 5 10 NO.1 SEQ NO.2 S

- Page 668 and 669:

Figure FO-4. DC Power Supply (Typic

- Page 670 and 671:

EAPS 1 FAN EAPS 2 FAN Figure FO-6.

- Page 672:

APPENDIX A REFERENCES TM 1-1520-240

- Page 675 and 676:

TM 1-1520-240-10 ABBREVIATION TERM

- Page 677 and 678:

TM 1-1520-240-10 ABBREVIATION TERM

- Page 679 and 680:

TM 1-1520-240-10 APPENDIX C CONDITI

- Page 681:

CONDITION 2408-13-1 ENTRY REQUIRED

- Page 684 and 685:

TM 1-1520-240-10 Subject Paragraph,

- Page 686 and 687:

TM 1-1520-240-10 Subject Paragraph,

- Page 688 and 689:

TM 1-1520-240-10 Subject Paragraph,

- Page 690 and 691:

TM 1-1520-240-10 Subject Paragraph,

- Page 692 and 693:

TM 1-1520-240-10 Subject Paragraph,

- Page 694 and 695:

TM 1-1520-240-10 Subject Paragraph,

- Page 696 and 697:

TM 1-1520-240-10 Subject Paragraph,

- Page 698 and 699:

TM 1-1520-240-10 Subject Paragraph,

- Page 700 and 701:

TM 1-1520-240-10 Subject Paragraph,

- Page 703:

By Order of the Secretary of the Ar

- Page 707 and 708:

RECOMMENDED CHANGES TO PUBLICATIONS

- Page 709 and 710:

RECOMMENDED CHANGES TO PUBLICATIONS

- Page 711 and 712:

RECOMMENDED CHANGES TO PUBLICATIONS

- Page 713 and 714:

The Metric System and Equivalents L