Digital Submerged Arc Welding Systems - Lincoln Electric

Digital Submerged Arc Welding Systems - Lincoln Electric

Digital Submerged Arc Welding Systems - Lincoln Electric

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE LINCOLN ELECTRIC COMPANY<br />

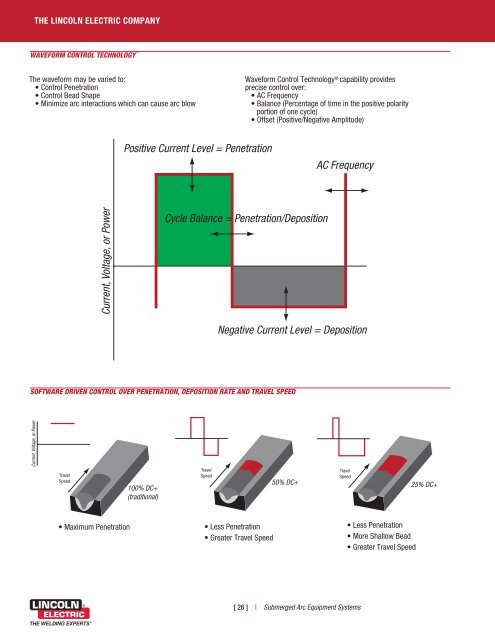

WAVEFORM CONTROL TECHNOLOGY ®<br />

The waveform may be varied to:<br />

• Control Penetration<br />

• Control Bead Shape<br />

• Minimize arc interactions which can cause arc blow<br />

Current, Voltage, or Power<br />

Travel<br />

Speed<br />

Current, Voltage, or Power<br />

Positive Current Level = Penetration<br />

100% DC+<br />

(traditional)<br />

Cycle Balance = Penetration/Deposition<br />

AC Frequency<br />

Negative Current Level = Deposition<br />

SOFTWARE DRIVEN CONTROL OVER PENETRATION, DEPOSITION RATE AND TRAVEL SPEED<br />

Travel<br />

Speed<br />

• Maximum Penetration • Less Penetration<br />

• Greater Travel Speed<br />

Waveform Control Technology ® capability provides<br />

precise control over:<br />

• AC Frequency<br />

• Balance (Percentage of time in the positive polarity<br />

portion of one cycle)<br />

• Offset (Positive/Negative Amplitude)<br />

50% DC+<br />

Travel<br />

Speed<br />

[ 26 ] | <strong>Submerged</strong> <strong>Arc</strong> Equipment <strong>Systems</strong><br />

Greater Travel Speed<br />

• Less Penetration<br />

• More Shallow Bead<br />

• Greater Travel Speed<br />

25% DC+