Finger Joint Cutters

Finger Joint Cutters

Finger Joint Cutters

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Finger</strong> <strong>Joint</strong>ing<br />

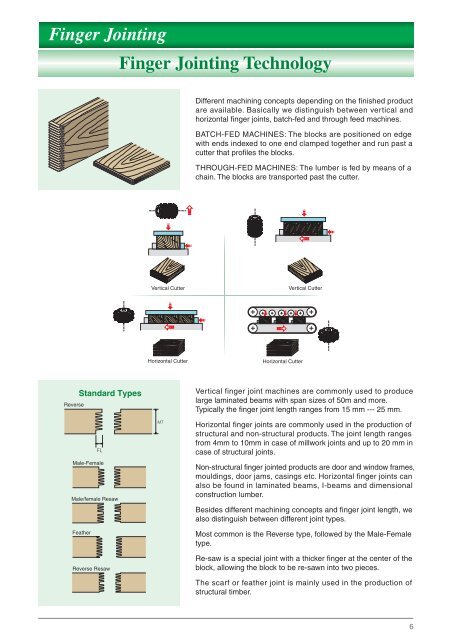

Reverse<br />

Standard Types<br />

FL<br />

Male-Female<br />

Male/female Resaw<br />

Feather<br />

Reverse Resaw<br />

<strong>Finger</strong> <strong>Joint</strong>ing Technology<br />

Vertical Cutter<br />

Horizontal Cutter<br />

MT<br />

Different machining concepts depending on the finished product<br />

are available. Basically we distinguish between vertical and<br />

horizontal finger joints, batch-fed and through feed machines.<br />

BATCH-FED MACHINES: The blocks are positioned on edge<br />

with ends indexed to one end clamped together and run past a<br />

cutter that profiles the blocks.<br />

THROUGH-FED MACHINES: The lumber is fed by means of a<br />

chain. The blocks are transported past the cutter.<br />

Horizontal Cutter<br />

Vertical Cutter<br />

Vertical finger joint machines are commonly used to produce<br />

large laminated beams with span sizes of 50m and more.<br />

Typically the finger joint length ranges from 15 mm --- 25 mm.<br />

Horizontal finger joints are commonly used in the production of<br />

structural and non-structural products. The joint length ranges<br />

from 4mm to 10mm in case of millwork joints and up to 20 mm in<br />

case of structural joints.<br />

Non-structural finger jointed products are door and window frames,<br />

mouldings, door jams, casings etc. Horizontal finger joints can<br />

also be found in laminated beams, I-beams and dimensional<br />

construction lumber.<br />

Besides different machining concepts and finger joint length, we<br />

also distinguish between different joint types.<br />

Most common is the Reverse type, followed by the Male-Female<br />

type.<br />

Re-saw is a special joint with a thicker finger at the center of the<br />

block, allowing the block to be re-sawn into two pieces.<br />

The scarf or feather joint is mainly used in the production of<br />

structural timber.<br />

6